The foundry industry uses screw conveyors to handle bulk materials, mainly when the material type is liquid or granular. Some semi-solid materials such as wood chips, aggregates, food waste, bone meal, ash and many other materials can be transported by screw conveyors, but screw conveyors also have some limitations, this article will analyze the advantages and disadvantages of screw conveyors for you:

1. It can handle different types of material types. It can be slow or free flowing.

2. There are multiple inlets and outlets, which can discharge materials at various points required, and can also control the flow of materials with the help of sliding doors or valves.

3. They are adjustable and can be accommodated in smaller spaces.

4. Screw conveyors are used in some industries to mix various materials and break clumps.

5. The custom screw conveyor without a central shaft (ie, shaftless screw conveyor) can be used for conveying wet, slow and viscous materials in the industry.

6. The screw conveyor can also help to heat, cool or dry the material. Internal pressure and steam can be maintained. This is very important when we are dealing with toxic or hazardous materials.

7. The auger screw conveyor is easy to install and safer when working in a higher position.

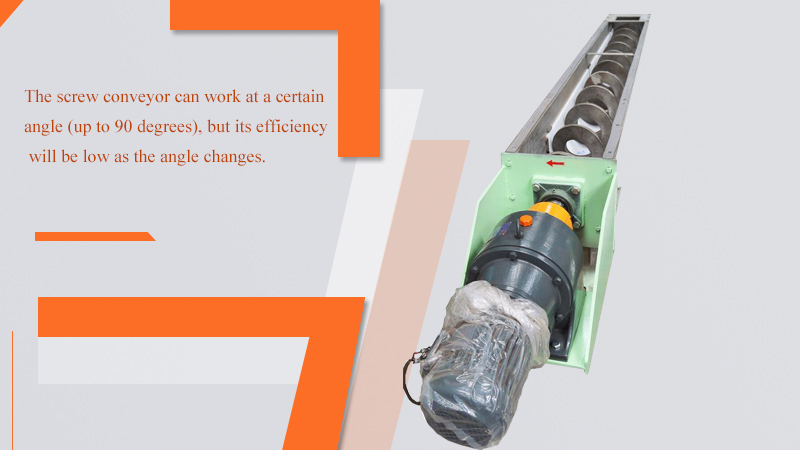

1. The screw conveyor can work at a certain angle (up to 90 degrees), but its efficiency will be low as the angle changes.

2. If the material is fragile or brittle, it cannot be used.

4. Abrasive and rough materials can also cause wear of the screw shaft.

The above is that a screw conveyor is a machine after all. It has a working limit which depends on several factors such as material density, grain size, rotational speed, angle of work, etc. However, each industry type requires a different type of screw conveyor. Therefore, before choosing a screw conveyor, you must know your material type.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.