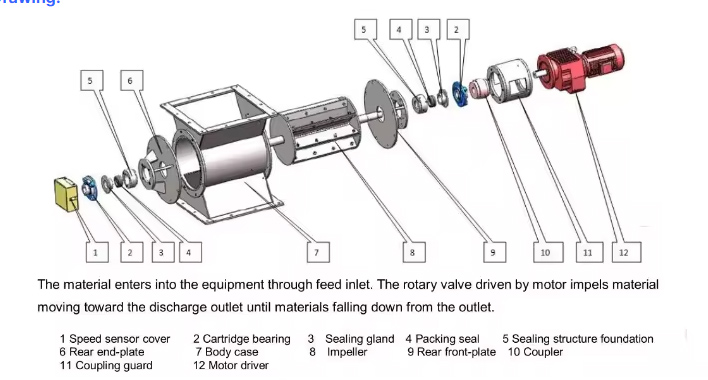

The device pushes the material to the discharge port through the rotating star-shaped spiral blades.

![]()

![]()

![]()

Price:$200.00-$800.00/Set

Consult now and enjoy a 10% discount

Diameter: 150-400mm

Discharge per revolution: 0.005-0.045m³/r•p•m

Impeller speed: 10-35r•p•m

Feeding rate: 2-90m³/h

Motor power: 0.75-3KW

Frame Material: Carbon Steel/Stainless Steel

Application: It is particularly suitable for dust and small particle materials, and is used in environmental protection, metallurgy, chemical industry, grain, cement and other industries.

Commitment:

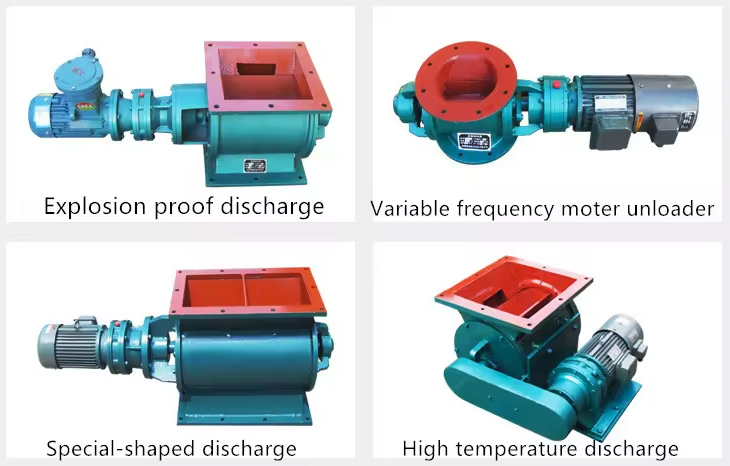

The star discharger consists of a rotor with multiple blades or vanes arranged in a star-shaped configuration. This rotor rotates within a housing, creating a seal between the inlet and outlet of the material storage vessel. As the rotor turns, the blades sweep the material evenly towards the outlet, allowing for a controlled and uniform discharge of bulk materials.

The star discharger, also known as a star unloader or rotary valve discharger, is a critical component in material handling systems, particularly in industries such as agriculture, food processing, mining, and manufacturing. This specialized equipment is designed to efficiently and evenly discharge bulk materials from silos, hoppers, or bins, ensuring a continuous flow of materials and preventing blockages.

Star discharger is often used in dust removal system as one of the important equipment of dust removal system. It is particularly suitable for dust and small particles, and is widely used in food processing, metallurgy, chemical industry, grain, cement, road construction, drying equipment and other industrial industries.

Material Discharge: The primary function of the star discharger is to discharge bulk materials such as grains, powders, pellets, and other granular substances from storage vessels like silos, hoppers, and bins.

Preventing Bridging and Blockages: The rotating blades of the star discharger help prevent material bridging and blockages within the storage vessel, ensuring a consistent flow of materials and preventing downtime.

Batching and Feeding Systems: Star dischargers are commonly used in batching and feeding systems to deliver precise amounts of materials to downstream processes, such as mixers, conveyors, or packaging machines.

Dust Control: Some star dischargers are equipped with features for dust control, helping to minimize dust emissions during material discharge and transfer.

Star discharger has a simple structure and reliable operation, and is suitable for efficient and stable unloading of granular materials in various industrial fields. It has the following characteristics and advantages:

Uniform Material Flow: The star discharger ensures a uniform and controlled flow of materials, preventing uneven discharge and material segregation.

Reliable Operation: With its robust construction and efficient design, the star discharger offers reliable and continuous operation, reducing the risk of downtime and production interruptions.

Versatility: Star dischargers are versatile and can handle a wide range of bulk materials, making them suitable for various industries and applications.

Low Maintenance: These machines are designed for easy maintenance, with minimal wear and tear on components, leading to reduced maintenance costs and increased operational efficiency.

Safety: Star dischargers are equipped with safety features to protect operators and ensure safe handling of materials during the discharge process.

The working principle of the star discharger is as follows: the material enters the container of the discharger from above. There is a star-shaped spiral blade inside the container. When the motor drives the spiral blade to rotate, the material is pushed toward the discharge port. Due to the special shape of the spiral blade, the material is gradually squeezed and pushed during the movement, and finally discharged smoothly through the discharge port.

A food processing company uses a star discharger in its production process to transport grains from the storage warehouse to the production line. This equipment helps the company achieve efficient material transportation and ensures the continuity and stability of production. The uniform discharge characteristics of the star discharger allow grains to be transported smoothly, avoiding blockages and material waste. By optimizing the material transportation process, the company has improved production efficiency, reduced production costs, and ensured product quality.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.