Transfer powder and small granular materials from top storage bins or hoppers to bottom discharge ports for uniform or variable-speed feeding

![]()

![]()

![]()

Price:$200.00-$800.00/Set

Consult now and enjoy a 10% discount

Diameter: 150-400mm

Discharge per revolution: 0.005-0.045m³/r•p•m

Impeller speed: 10-35r•p•m

Feeding rate: 2-90m³/h

Motor power: 0.75-3KW

Frame Material: Carbon Steel/Stainless Steel

Application: Continuous and uniform conveying of dust, pulverized coal and other dry materials (particle size less than 10 mm)

Commitment:

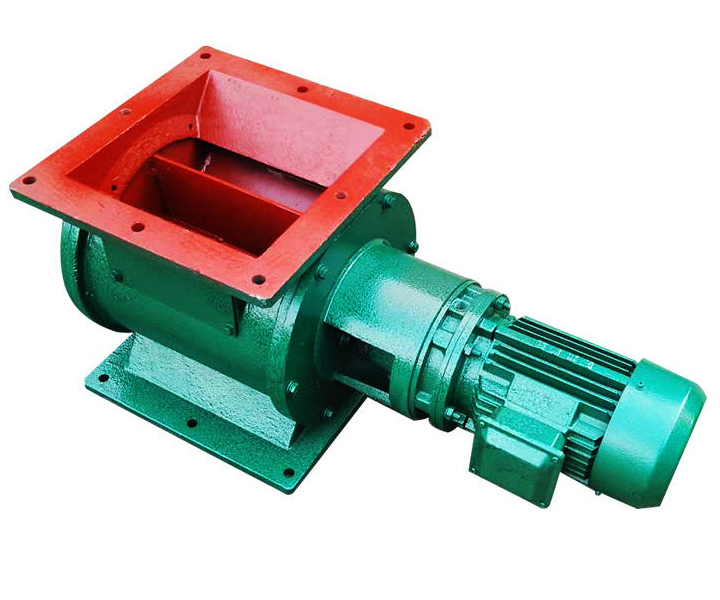

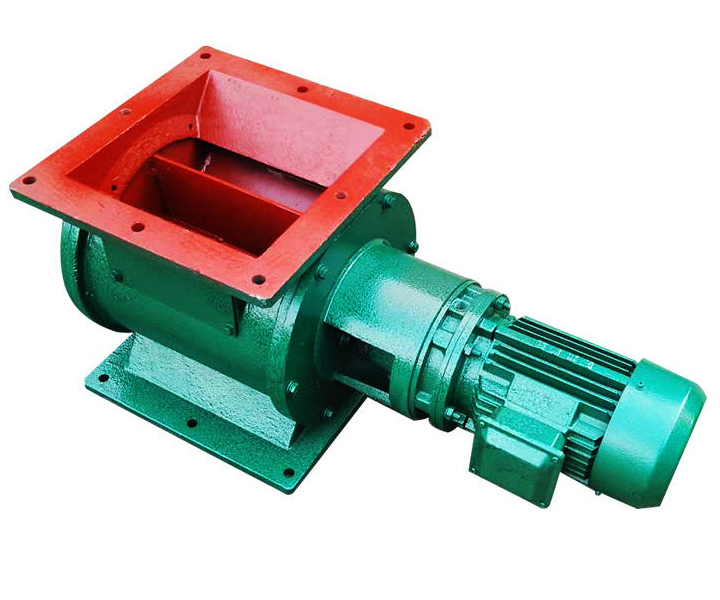

Impeller feeder, also known as rigid impeller feeder, electric discharge valve, star discharge valve, etc., uses a rotating impeller with compartments to transport powder and small granular materials from the upper storage bin or hopper to the lower discharge. It is specially designed for storage, feeding powder engineering, quantitative feeding and ash discharge in the air dust removal equipment system.

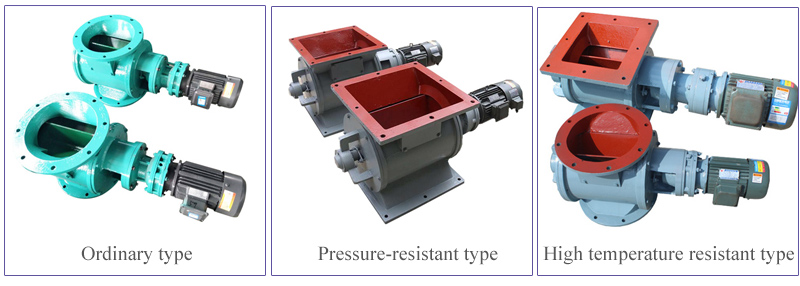

Impeller feeder is divided into three categories: ordinary type (represented by code J), pressure-resistant type (represented by code N), and high-temperature resistant type (represented by code H):

1. Ordinary type: The upper and lower flanges of the impeller feeder are basically square or round, and can also be selected by the user. The ordinary type is generally suitable for no wind pressure.

2. Pressure-resistant type: The characteristic of this type of rotary blanking valve is that the end of the rotor blade is made of special wear-resistant material, which can ensure that the blade end has a good contact with the inner wall of the shell, and the blade end can be easily adjusted after wear. , so that it still maintains good contact with the inner wall of the casing. If the closed rotor has better air-locking performance, the wear-resistant type is mainly suitable for materials with strong grinding performance.

3. High temperature resistant type: the temperature of the conveyed material can reach 280 ℃, and the bearings at both ends are isolated from the impeller, which can prevent the ultra-fine powder from contacting the bearing.

The main function of impeller feeder is to control silos, mixers, cyclones or hoppers to discharge bulk materials under the action of gravity. It is specially designed for bulk material unloading devices under dust removal equipment, silos, storage silos, hoppers, etc. Feeding equipment for material systems in building materials, chemical industry, metallurgy, light industry and other industries.

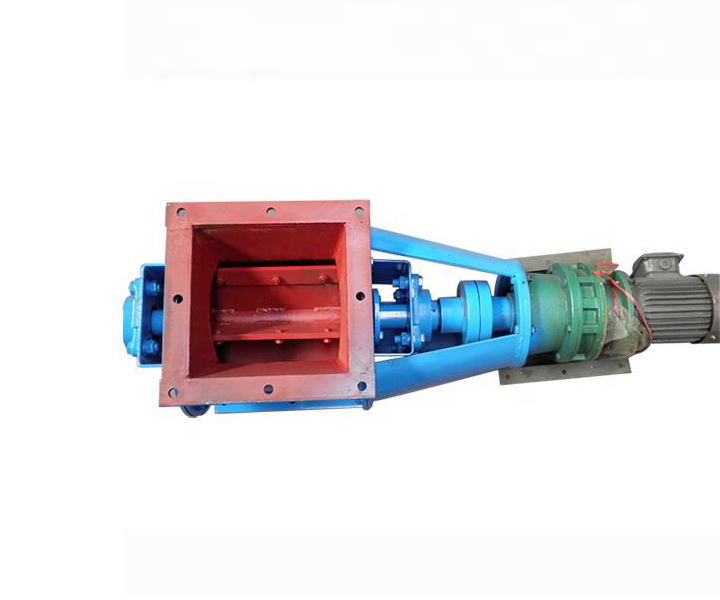

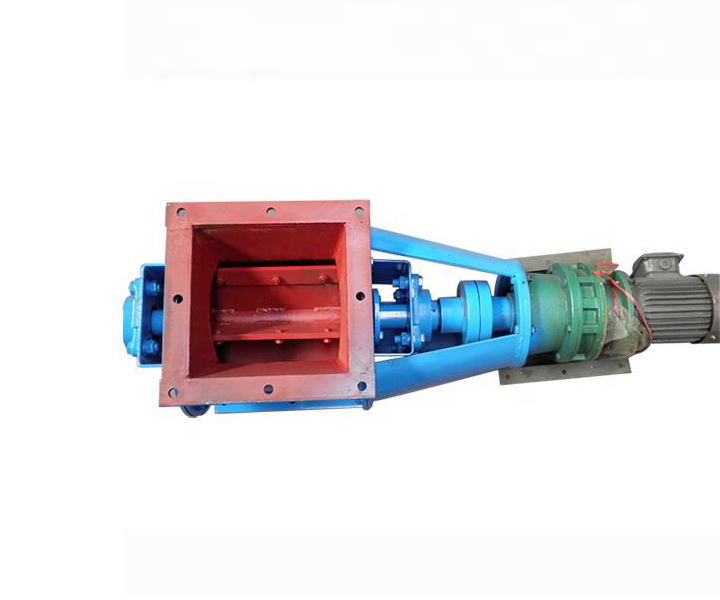

The Impeller feeder is driven by the motor through the speed reducer to drive the main shaft and the impeller to rotate, so that the material enters the impeller groove from the upper silo through the feed port, and the rotating impeller brings the material to the discharge port and feeds it out. It is a uniform and continuous batching, conveying and unloading equipment in a mechanized and automatic control system.

Discharge evenly and continuously

When the material in the upper silo falls by its own weight and fills the gap between the blades, it is discharged from the lower part with the rotation of the blade, which can realize quantitative and continuous discharge.

Adjustable feeding amount

The feeding amount can be adjusted at any time by adjusting and changing the speed of the impeller, which is easy to operate, and is often used as the unloader of the silo in the dust removal system.

Sealing system

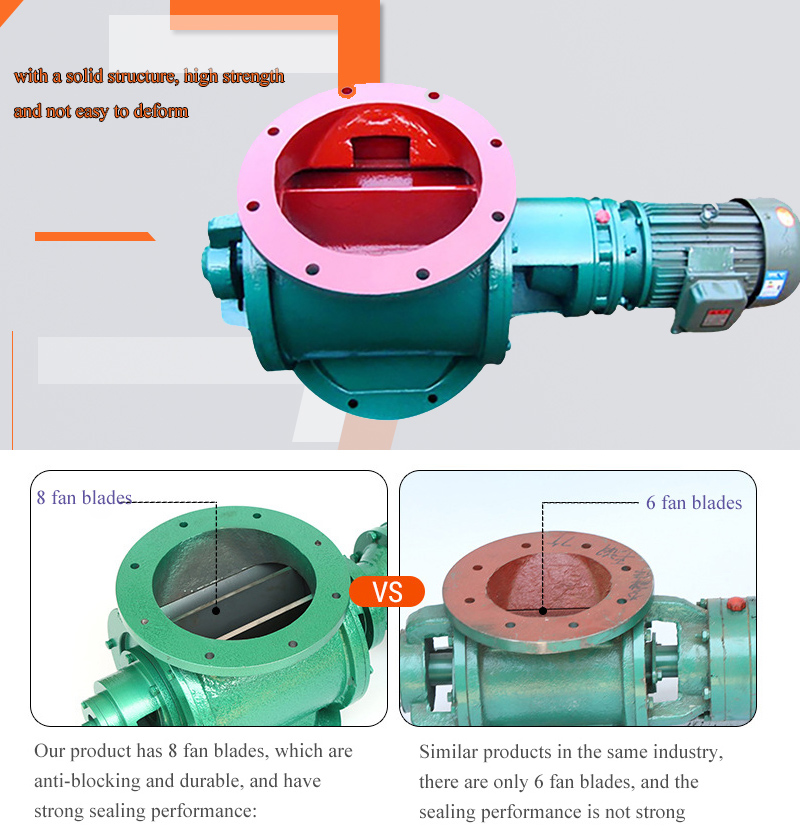

Bearings and gearboxes are far away from the valve body to avoid the influence of high temperature dust and prevent dust leakage.

Multi-purpose machine

It can also remove dust and impurities while unloading, and has a moving friction cleaning effect on the surface of the product.

Less wear

The outer body design of the bearings at both ends reduces dust entering the bearing, which is a good way to reduce wear.

Customizable

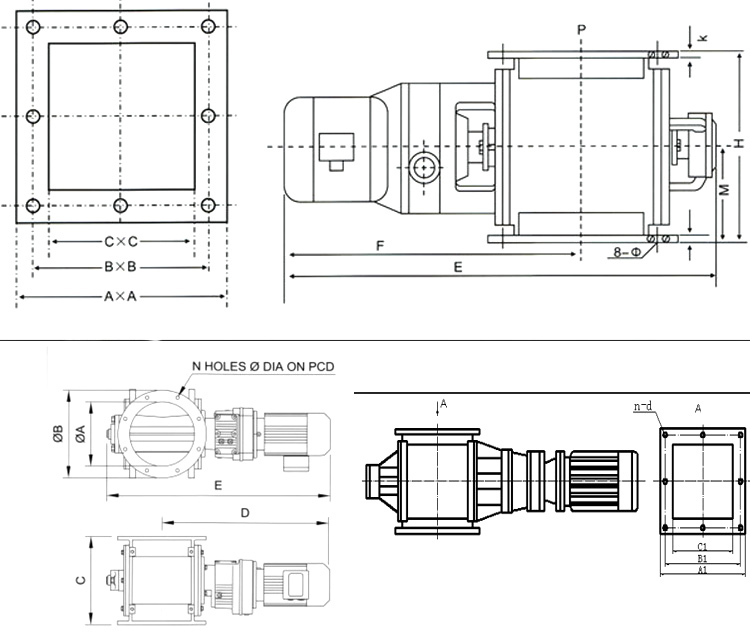

The discharge port can be designed in different styles such as round or square according to the different needs of customers.

| Model | JL200 | JL300 | JL400 | JL500 | JL630 | JL1000 | ||||||

| Impeller size(mm) | 200*200 | 300*300 | 400*400 | 500*500 | 630*600 | 1000*1000 | ||||||

| Capacity per revolution(m3/(r·p·m) | 0.005 | 0.018 | 0.045 | 0.05 | 0.09 | 0.11 | ||||||

| Impeller speed(r·p·m) | 10 | 19 | 19 | 25.5 | 25.5 | 35 | 25 | 35 | 20 | 28 | 20 | 28 |

| Theory feeding capacity(m3/h) | 3 | 6 | 20 | 27 | 68 | 90 | 75 | 105 | 108 | 126 | 154 | 192 |

| Rated feed ability(m3/h) | 2 | 4 | 15 | 20 | 60 | 80 | 70 | 90 | 98 | 110 | 132 | 160 |

| motor power(kw) | 0.75 | 0.75 | 1.5 | 2.2 | 3 | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 | 7.5 |

| Reducer Model | BW1 | BW2 | BW2 | BW3 | BW4 | BW5 | ||||||

| Max material size(mm) | 30 | 45 | 50 | 60 | 75 | 110 | ||||||

1. The name of the conveyed material, the specific gravity of the material, and the material is powder or small granular.

2. Conveying capacity: The size of the impeller feeder and the speed ratio of the reducer can be selected according to the conveying capacity. Determine the output of the impeller feeder, and select the appropriate diameter of the impeller feeder according to the output. Select the appropriate diameter of the impeller feeder. The normal diameter of the impeller feeder is round or square at the top and bottom. When non-standard customization, it can be made into an upper circle and a lower circle or an upper circle and a lower circle.

3. When the basic model of the impeller feeder is determined, it is necessary to pay attention to whether the working environment of the impeller feeder has "positive pressure" or "negative pressure". When there is wind pressure, the impeller feeder must be selected as air lock Type, there is generally mechanical air lock, which is to mechanically finish the impeller and valve body of the impeller feeder. After finishing, the gap is small, and the material fills the gap during work to achieve the purpose of air lock. In addition, there is a flexible air lock. According to different materials, wear-resistant canvas belts and thin stainless steel sheets can be selected, which are fixed on the rim of the impeller and exceed the rim by 5-10mm. During the rotation process, the deformation of the stainless steel sheet or the canvas belt is used to block the wheel. The gap between the edge and the valve body can achieve the purpose of locking the wind.

4. Whether there is high pressure in the working conditions of the impeller feeder, if there is high pressure, the valve body of the impeller feeder and the outer circle of the impeller of the impeller feeder need to be finished to achieve the purpose of locking and closing the air.

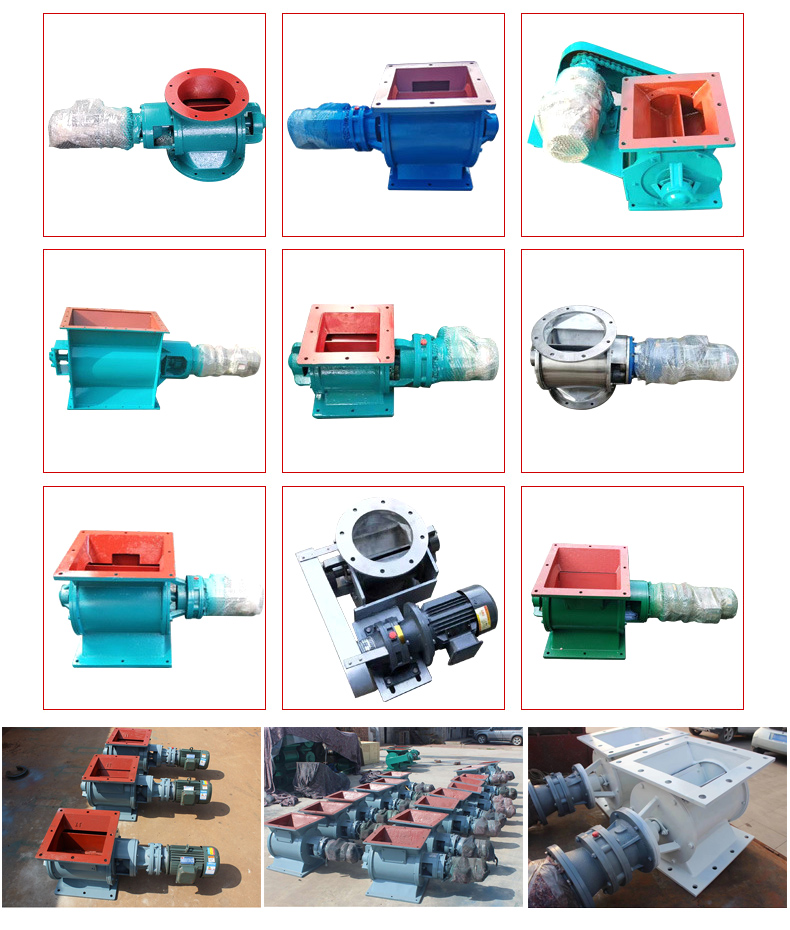

Xinxiang Dahan impeller feeder manufacturers produce various specifications. The flange of the ash discharge valve is divided into: (round mouth, square mouth), the shell raw materials are divided into: (cast iron, carbon steel, stainless steel), etc. The ash discharge valve transmission is divided into: ( Direct connection type, chain type), can be equipped with variable frequency motor and general motor, etc. There are conventional types of ash discharge valves, and the caliber and discharge volume can also be customized according to user needs.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.