Particle Size Test in Pharmaceuticals automatically determines the number of particles based on particle size, accurately measuring the particle size distribution (range 0.005 - 50 micrometers) of dry and wet bulk drugs. The system automatically counts particles based on size, providing precise particle size analysis data to optimize drug dissolution and bioavailability, ensuring formulation homogeneity and final product quality, fully complying with stringent pharmaceutical industry regulations.

The pharmaceutical company focuses on the development and production of solid pharmaceutical dosage forms such as tablets, capsules and granules. They need to conduct particle size testing to evaluate the size distribution of drug particles to ensure that the product's quality, stability and dissolution properties meet pharmacopoeia standards and regulatory requirements.

The particle size distribution of drug particles has an important impact on the bioavailability and efficacy of drugs. Customers require accurate and reliable measurement of the particle size characteristics of pharmaceutical particles for quality control, process optimization and product improvement. They face the following challenges:

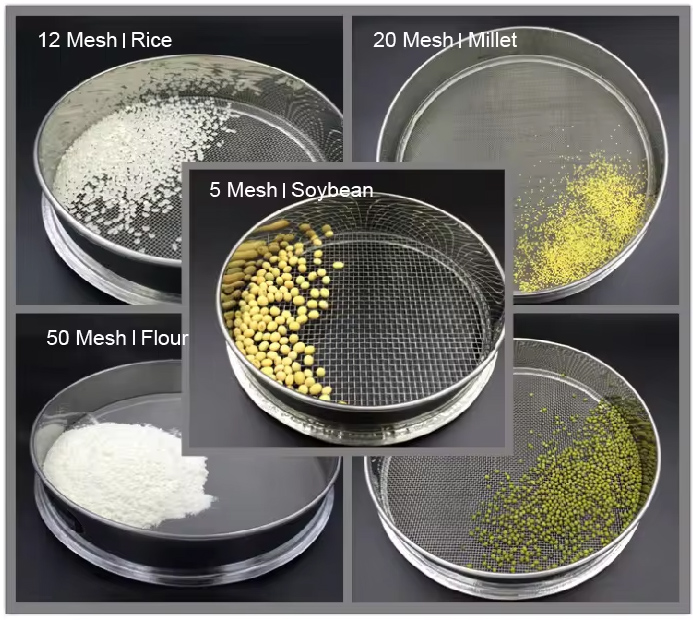

Wide range of particle sizes: Different pharmaceutical dosage forms have different particle size requirements, ranging from micron to millimeter particle sizes. The customer needed a test method that could accurately measure particles across a wide range of particle sizes.

Precision and repeatability: Particle size testing requires high precision and repeatability to ensure accuracy and consistency of test results.

Speed and efficiency: Customers want to be able to complete particle size testing of a large number of samples in a short time to improve production efficiency and laboratory work efficiency.

To meet customer needs, pharmaceutical companies have adopted the following solutions:

Test screening equipment: The customer used high-precision test screening equipment, such as a rotary test sieve machine. This equipment can separate and classify particles by passing samples through sieves of different particle sizes in a controlled vibration manner.

Multi-sieve mesh combination: Customers choose appropriate mesh size combinations based on different particle requirements. By using different sized mesh openings, they can analyze and control particles in different size ranges.

Screening speed and efficiency: In order to improve screening efficiency, the customer reasonably arranged the sample processing sequence and adopted an efficient vibration screening method. They also conduct necessary operational training to ensure that operators can operate the equipment proficiently.

Through particle size testing, drug manufacturers can obtain important information about the particle size of drug products. They can evaluate whether a product meets the required particle size range, optimize process parameters to improve product performance, and ensure product consistency and quality. In addition, particle size analysis helps them meet pharmacopeial standards and regulatory requirements to ensure product safety and effectiveness.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.