Flour is a powder made from wheat and is the staple food in most parts of northern China. For the flour industry, the fineness requirements for flour are very fine, so it is necessary to use a flour screening machine to screen coarse particles and impurities in the flour, and to use a vibrating sieve for the screening and removal of flour. Dahan will answer the meaning for you next.

The purpose of flour screening mainly includes the requirements of impurity removal and sieve loosening. Therefore, for different purposes, Dahan manufacturers recommend the following three vibrating screens for everyone to choose:

Mesh number: 140 mesh Capacity: 3~30 tons/hour

| PRODUCT | PROPORTION | MESH OPENING | CAPACITY (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | 3200 IT |

| Flour | 0.6 | 24 | 1500㎏ |

| Rice flour | 0.5 0.8 | 100 | 300 ㎏ |

| Pollen | 0.4 | 12 | 100㎏ |

| Skim milk powder | 0.57-0.7 | 24 | 3000㎏ |

| Whole milk powder | 0.57-0.8 | 12 | 1600㎏ |

| Rice bran | 0.5 | 16 | 500㎏ |

| Instant soup powder | 0.6-0.8 | 6.8 | 360㎏ |

| Powdered sugar | 0.5-0.8 | 100 | 200㎏ |

In more large-scale flour production lines, such as flour mills, most of them use central discharge vibrating screen to screen and remove flour.

The flour central discharge vibrating screenn seals energy consumption, avoids the dusting phenomenon of the flour during the screening process, thus ensuring the screening precision of the flour. It can be used in single or multi-layer, automatic operation, and can be continuously produced in 24 hours, which is in line with the rough removal of flour. Miscellaneous and high production requirements.

Mesh number: 400 mesh Capacity: 100-2000 kg/h

| PRODUCT | PROPORTION | MESH OPENING | CAPACITY kg/h |

MODEL |

| flour | 0.6 | 24 mesh | 1500 | DZSF-515-3S |

| Iron ore powder | 2.3 | 150 mesh | 10000 | DZSF-1020-3s |

| Sawdust | 0.2 | 80 mesh | 18000 | DZSF-1030-3S |

| Wood flour | 0.4 | 120 mesh | 2000 | DZSF-1036-4s |

As a high-precision fine powder screening equipment, the vibro sifter can not only screen the impurities of flour, but also sieve the flour to meet the screening requirements of customers. In general, the screening accuracy of flour is required to be 400 mesh, which is very suitable for screening by vibrating sieve.

The flour vibro sifter can screen particles as fine as 500 mesh or 0.028 mm, and is equipped with a cleaning device to reduce the phenomenon of blockage of the material during the screening process, greatly improving the screening output and screening of the screening machine.

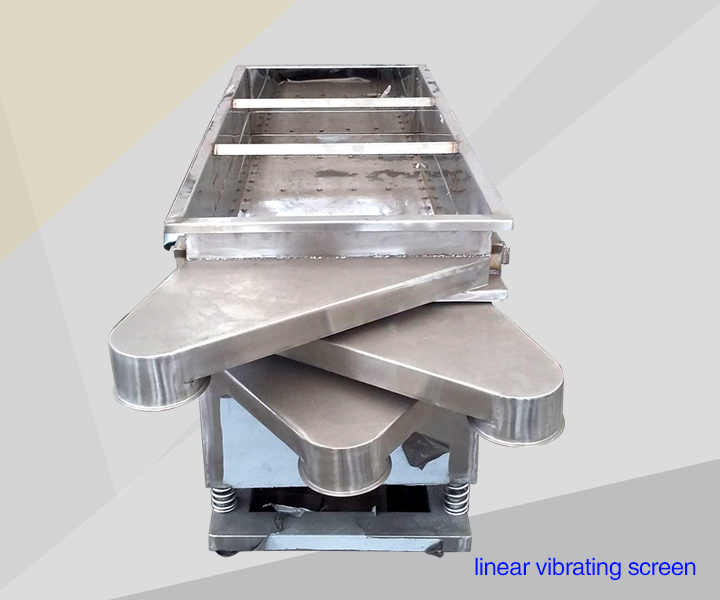

Summary: In the above three vibrating screens, if the user requires high screening accuracy, the vibro siftern should be preferred, but the simple de-mixing can select the central discharge vibro sifter and the linear vibrating screen, the central discharge vibrating screen output and the linear vibrating screen output. Regardless of the upper and lower, but because the price of the linear vibrating screen is cheaper than that of the central discharge vibrating screen, the user prefers to select the linear vibrating screen instead of the central discharge vibrating screen

In summary, the use of the vibrating screen for the screening and removal of flour is also subject to the actual conditions of the user's screening machine. Dahan provides one-on-one technical guidance. If you have any questions, please feel free to contact us.

Mesh number: 400 mesh Capacity: 0.12-20 tons/hour

| PRODUCT | MESH OPENING | DH-600 | DH-800 | DH-1200 | DH-1500 |

| Milk powder | 400µ | 350Kg/h | 800Kg/h | 1.800Kg/h | 2.800Kg/h |

| Species (oregano, thyme, cinnamon…) | 600µ | 400Kg/h | 1.000Kg/h | 1.500Kg/h | 1.800Kg/h |

| Sweet pepper | 1000µ | 180Kg/h | 350Kg/h | 1.000Kg/h | 1.300Kg/h |

| Serum lactic | 50µ | 1.000l/h | 2.200l/h | 5.000l/h | 7.500l/h |

| Sugar glass | 150µ | 800 Kg/h | 2.000 Kg/h | 3.000 Kg/h | 3.500Kg/h |

| Wheat flour | 300µ | 300 Kg/h | 600 Kg/h | 1.350 Kg/h | 2.100Kg/h |

| Ammonium sulfate | 350µ | 400Kg/h | 900Kg/h | 2.000Kg/h | 3.100Kg/h |

| Toner powder | 100µ | 90Kg/h | 170Kg/h | 400Kg/h | 600Kg/h |

| Glass powder | 100µ | 270Kg/h | 500Kg/h | 1.300Kg/h | 2.000Kg/h |

| Shredded tire | 1000µ | 300Kg/h | 650Kg/h | 1.500Kg/h | 2.200Kg/h |

| Purines | 125µ | 2.000l/h | 4.000l/h | 10.000l/h | 15.000l/h |

| Acrylic paint | 80µ | 500l/h | 1.200l/h | 2.700l/h | 4.200l/h |

The linear vibrating screen is mainly for simple classification and impurity removal of impurities in the flour.

The flour linear vibrating screen can be used in one layer or in multiple layers. It can be divided into 6 different materials at a time. One machine can realize multiple functions. The screening and classification accuracy is over 96%, and the screening efficiency is high. Closed structure, no dust and overflow, automatic discharge, more suitable for the assembly line of flour.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.