vibratory sieve

vibratory sieve stainless steel vibratory sieve

stainless steel vibratory sieve multi-layer vibratory sieve

multi-layer vibratory sieve plastic vibratory sieve

plastic vibratory sieve industrial vibratory sieve

industrial vibratory sieve

Safety screening for the elimination of foreign bodies, separation of different particle sizes in the same product, and solid-liquid separation

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Function:Screening, separation, sorting, sieving, grading

Diamater:400-2000mm or customized

Screen Mesh:2-500 Mesh Capacity:100Kg-10Tons/hour

Layer:1-5 layer

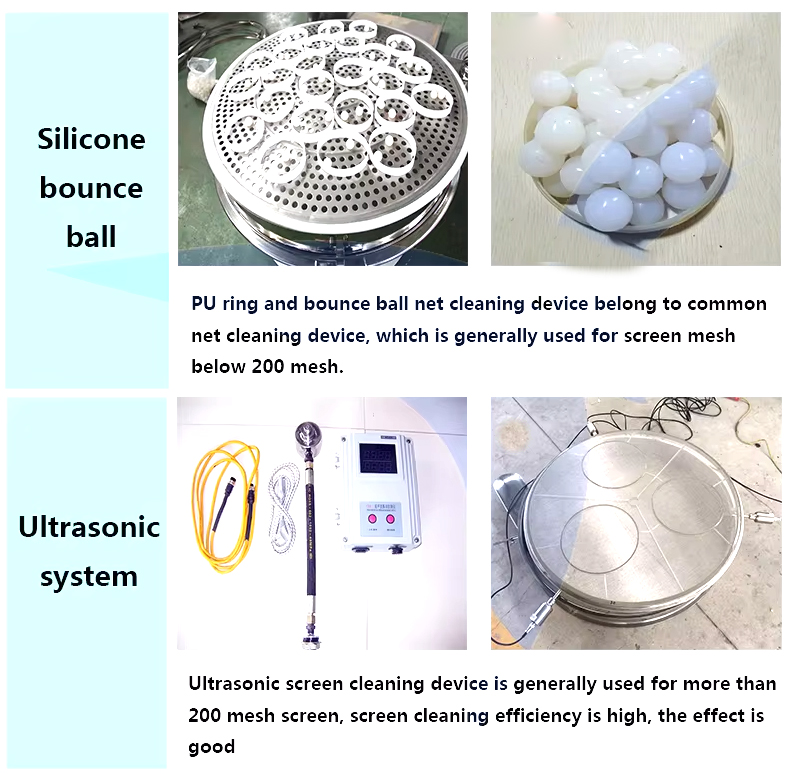

Cleaning system:Bouncing Ball,Ultrasonic System

Voltage:110V/220V/380V/415V/460V

Powder:0.18-2.22KW

Material:Carbon Steel, Stainless Steel 304/316L

Noise level:75db

Application: Widely used in food processing, mineral screening, pharmaceutical raw material screening, chemical raw material screening and other industries

Commitment:

Vibratory sieve is used for accurate batch grading or safe screening of powders and liquids, it removes oversized contaminants from your powders and liquids, it also accurately separates your powders and granules It can be divided into different sizes, And can separate up to 6 grades of products in one operation, and our sieves require minimal headroom for easy integration into your production line, widely used in food and beverage, pharmaceutical, powder coating, metal powder, chemical, Agriculture, plastics and other industries.

Vibratory sieves are available in diameters of 400, 600, 800, 1000, 1200, 1500, 1800, 2000mm, allowing throughputs from 100 to 5,000 kg/h, depending on the product, mesh size and machine feed flow, and can be tailored to industry needs Choose carbon steel, stainless steel, plastic materials, and can also be designed into gate type, edged type, mobile type, etc.

Vibratory sieve is a vibratory sieve mechanical equipment that uses the relative motion of the bulk material and the sieve surface to make some particles pass through the sieve holes and divide the coarse material, medium material and fine material into different levels according to the particle size. Its main functions are as follows:

1. Removal of impurities: high fluidity powder processing, fast removal of large particles or fine powder with low content. Such as food powder, chemical powder, powder coating, pharmaceutical powder, etc.

2. Size classification: Continuously select mixed materials of different particle sizes and classify them into different particle size grades. Can be divided into one, two, three, four and so on. What's more, only one operation can continuously filter up to 5 stages of product separation. Such as grain, feed, fertilizer granules, plastic granules, etc.

3. Solid-liquid separation: quickly remove insoluble solids in various slurries, and remove unqualified impurities or suspended solids in slurries. If fruit juice, soybean milk, oil, grape juice, red wine, etc.

Dahan Machinery offers a wide range of vibratory sieves and separators for a wide range of applications, choose the type of screening system you need from the options below.

450 Filter Sieve

ISpecifically designed for filtering liquids, suitable for low-volume, low-impurity slurries, for filtering and eliminating suspended matter and unwanted particles in powders or liquids.

Direct Discharge Sifter

Suitable for rough inspection screening and impurity removal of powders and granules, ideal for screening incoming ingredients and final production inspection of finished products.

Centrifugal Sifter

Separate particles of different sizes into two product streams, remove pollutants in dry powder, and break up agglomerates at the same time, the output is 5-10 times that of ordinary vibratory sieve.

Ultrasonic Vibrating Sieve

It enables sieving on finer meshes (down to 20 microns) without any blocking

Industrial Vibratory Vieve

Ideal for screening incoming ingredients and final production checks on finished powders.

Laboratory Vibratory Sieve Shaker

Used for measuring powders and solid particles in the laboratory with a particle size range of 20 µm - 63 mm.

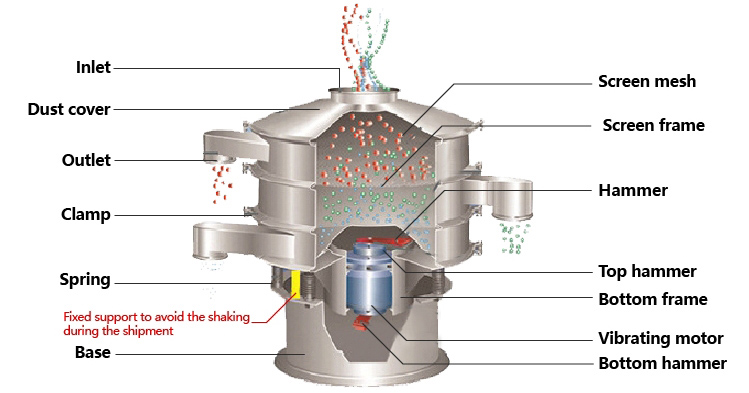

Material Feeding: The material to be sieved is fed onto the top sieve.

Vibration: The sieve machine creates a vertical or three-dimensional vibration. This vibration causes the material to move across the sieve surface.

Particle Separation: Particles larger than the mesh opening of a particular sieve are retained on that sieve, while smaller particles pass through to the next sieve.

Collection: The separated materials are collected in different compartments or containers.

Improve product quality

Eliminates oversizing and contamination in powder or liquid slurries, suitable for sieving from 36 microns to 25 mm.

Multi-layer separation

Up to 5 levels of classification can be provided in one operation for precise particle size distribution, for particle homogenization, etc.

High throughput

Impurities and coarse materials are automatically discharged, and after screening, they can enter the next round of screening work by themselves, allowing a production capacity of 100 to 5,000 kg/hour.

Not easy to block the mesh

The bouncing ball cleaning device is installed under the screen of each layer. By continuously hitting the screen, the material can be screened smoothly and effectively avoid the problem of material blocking the screen.

Totally closed system

Totally enclosed construction protects operator health and safety by reducing dust levels and providing a verifiable OEL5 seal (less than 1µg/m3).

Small footprint

The compact form requires minimal headroom, fits easily into your existing production line, and is available with installation castor wheels for easy movement inside plant if required.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibratory sieve has professional and unique design for the industry: vibratory sieve such as edge type, gate type, strong type, sealed type, mobile type, silo type, etc. At the same time, there are a variety of grid structure designs, allowing customers to have more choices.

| Type | Ultrasonic vibratory sieve | Gated vibratory sieve | Edged vibratory sieve | Vibratory sieve with silo |

|

|

|

|

|

| Features | Sieving on finer meshes (down to 20 microns) without any blocking or blinding of the aperture. | It can be used for a long-term screening operation at one time, and the opening and closing of the control gate can be used to achieve the purpose of good screening. | On the basis of ordinary vibratory sieve, the feeding port is enlarged, and the special angle is designed to prevent liquid splashing. | By adjusting the butterfly valve in the silo, the flow of the material is controlled, saving labor without the need for workers to continuously feed the material. |

| Application | It is suitable for fine powder materials with static electricity, adsorption and light specific gravity, such as graphite powder, phosphor powder, metal powder, etc. | It is mostly used for the screening of ultra-light and ultra-fine materials, such as traditional Chinese medicine powder, pollen and other industries. | Widely used in paint, water filtration, pulp filtration and other industries. | It is used in the environment where the screening place is not fixed, it is convenient for users to move, and it can meet the work needs of different places. |

Mesh cleaning: PU sliders, Silicone bouncing balls, and Ultrasonic system

| General requirements | Diameter Size(mm) | 400/800/1000/1200/1500/2000 |

| Number of Layers(L) | 1-5(Suggest ≤ 3) | |

| Material | Stainless Steel(304/316L)•Carbon Steel(Q235)•PP | |

| Screen Mesh Number | 5-500 mesh | |

| Screen cleaning device | Bouncing ball/brush/ultrasonic | |

| Sealing Strip | Silica gel / Rubber | |

| Special requirements | Overall height of the fuselage | Please communicate specifically |

| Feed inlet | Angle / Size and so on | |

| Outlet | Angle / Size /Add valve | |

| Observation port | Silicone cover / Rubber cover / Glass cover | |

| spring | You can choose whether to add a silicone protective cover | |

| Internal spray(mm) | PTFE / ePTFE / WC / Al2O3 | |

| Equipment surface treatment | Polishing / Sandblasting | |

| Body metal material requirements | For example: require no Cu and Zn (except electrical parts) | |

| Vibration motor | Ordinary motor / Explosion-proof motor |

The Vibratory sieve removes all oversized contaminants and is ideal for high volume safety screening of powders and liquid slurries. These screens fit neatly into the production line, providing considerable screening capacity without excessive headroom. , widely used in many of the following industries:

1. Chemical industry: resins, paints, industrial medicines, cosmetics, paints, herbal powders, etc.

2. Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

3. Metal and metallurgical mines: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod

4. Powder, manganese dioxide, electrolytic copper powder, electromagnetic material, grinding powder, refractory material, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

5. Other industries: waste oil, waste water, dyeing and finishing waste water, papermaking, additives, activated carbon.

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Medicine powder | 0.8 | 80 | DH-800-1S | 550㎏ | |

| Iron powder | 3 | 400 | DH-800-1S | 230㎏ | |

| Mica | 0.8 | 200 | DH-800-1S | 110㎏ | |

| Waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000IT |

Dahan vibratory sieve manufacturers have strictly formulated detailed quality management standards for each step from material selection, design, production to assembly and operation. Our products have successively obtained ISO and EU CE certification, and the quality is guaranteed. As a direct-sale vibratory sieve manufacturer, our price adopts a lower factory price to reduce the user's investment cost, and our product models are complete, and can also be customized for each user.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address::China,Yanjin county forest park gate to the west 1000 meters north road.