vibrating sieve shaker

vibrating sieve shaker stainless steel vibrating sieve shaker

stainless steel vibrating sieve shaker ultrasonic vibrating sieve shaker

ultrasonic vibrating sieve shaker electromagnetic vibrating sieve shaker

electromagnetic vibrating sieve shaker vibrating sieve shaker machine

vibrating sieve shaker machine

Typically used in laboratories for particle size analysis to separate particles by size by shaking the sieve in an oscillating motion

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

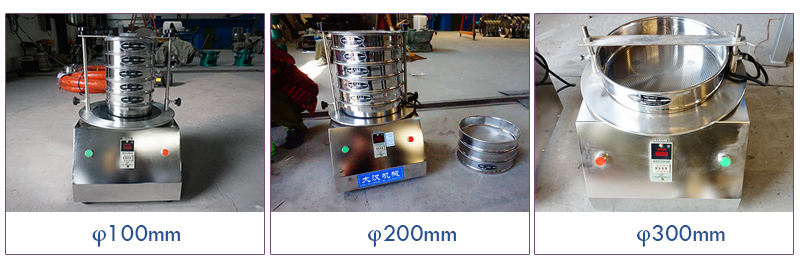

Diameter:200mm, 300mm, 400mm

Screen type:wire woven mesh, perforated plate screen

Screen material:brass, stainless steel, nylon

Measuring range:20µm-25mm

Feeding amount:≤200g

Layers:1-7 layers

Time display:1s-99 minutes

Voltage:220V Weight:43kg

Application:

Vibrating sieve shaker is used for dry and wet sieving of large batches up to 25 kg. It is suitable for sieves with diameters of 100 mm, 200 mm and 300 mm, and the controllable electromagnetic drive provides an optimum adaptation to the product requirements. Sharp parts are obtained even after very short sieving times, which can be used in the laboratory for particle size composition analysis and detection of powders, granules, liquids.

The primary purpose of a vibrating sieve shaker is to separate particles based on their size. Sieve shakers are commonly used in various industries, laboratories, and research settings for particle size analysis. Here are the key purposes and benefits of using a sieve shaker:

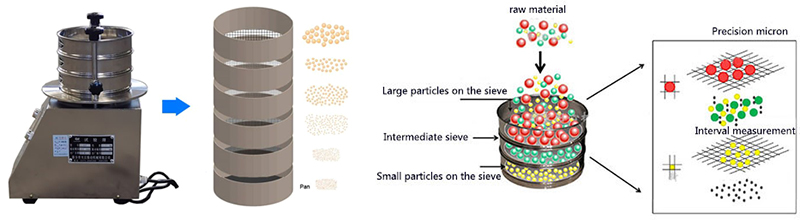

1.Particle Size Analysis: By passing the sample through a series of nested sieves with varying mesh sizes and subjecting them to mechanical vibrations, the vibrating sieve shaker separates particles based on their size.

2.Quality Control: In manufacturing and production processes, sieve shakers are used for quality control to ensure that materials meet specified particle size requirements.

3.Research and Development: Vibrating sieve shaker play a vital role in research and development activities across various industries. Researchers use sieve analysis data to study material properties, optimize processes, and develop new products.

4.Grading and Classification: Vibratory sieve shakers are used for grading and classifying materials based on particle size. This information is valuable in industries such as construction, pharmaceuticals, food processing, and mining.

5.Standardized Testing: Many industries and regulatory bodies have standardized testing methods that require the use of vibratory sieve shakers for particle size analysis. This ensures consistency and comparability of results across different laboratories.

Laboratory vibrating sieve shaker

Specialized equipment used in scientific laboratories for particle size analysis and quality control purposes. These devices are designed to efficiently separate particles based on their size using vibration and sieving techniques.

Measuring range: 20µm-25mm

Screen diameter: 200 mm / 300 mm

Ultrasonic vibrating sieve shaker

This technology involves the use of high-frequency ultrasonic vibrations to improve the efficiency and performance of particle size analysis. The ultrasonic energy assists in preventing particles from clogging the sieve apertures.

Measuring range: 20 µm - 40 mm

Screen diameter: 200 mm / 300 mm/

Rotap vibrating sieve shakerr

Widely used laboratory equipment for particle size analysis. It employs a unique shaking motion that effectively separates particles based on their size, utilizes a combination of horizontal and vertical movements to agitate the particles and facilitate their passage through sieves of different mesh sizes.

Slap times: 156±3 times/min

Slap height: 38±6mm

Electromagnetic sieve shaker

A type of sieve shaker that uses an electromagnetic drive mechanism to generate vibrations for particle size analysis. This technology is particularly effective for fine and ultrafine particles that may be challenging to separate using traditional sieve shakers.

Measuring range: 20 µm - 40 mm

Screen diameter: 200 mm / 300 mm

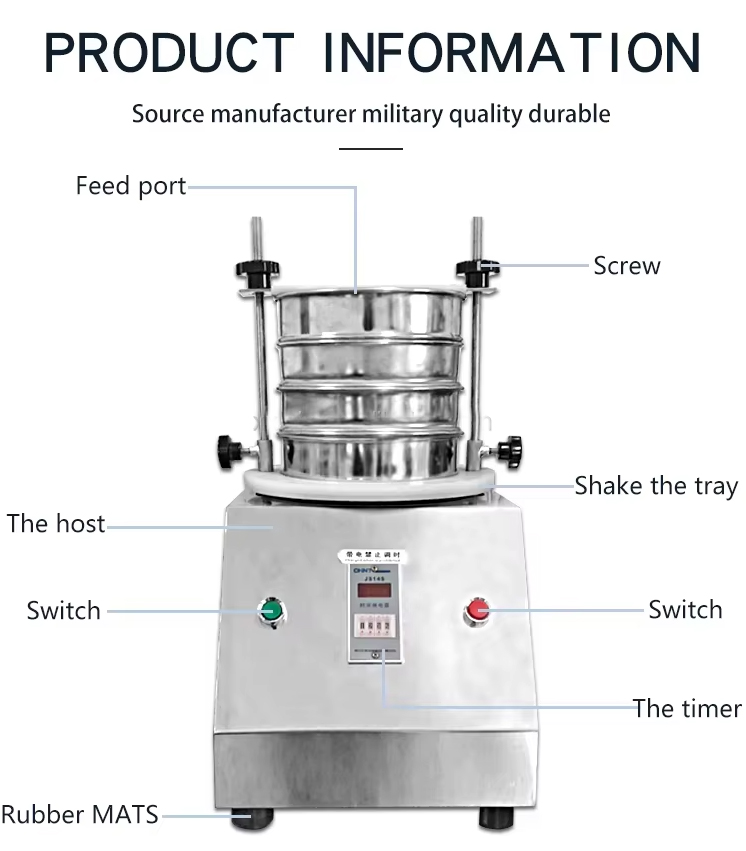

Vibration Mechanism: The vibrating sieve shaker consists of a vibrating platform or sieve deck that vibrates rapidly in a controlled manner. This vibration helps to move the particles on the sieve surface and aids in the separation process.

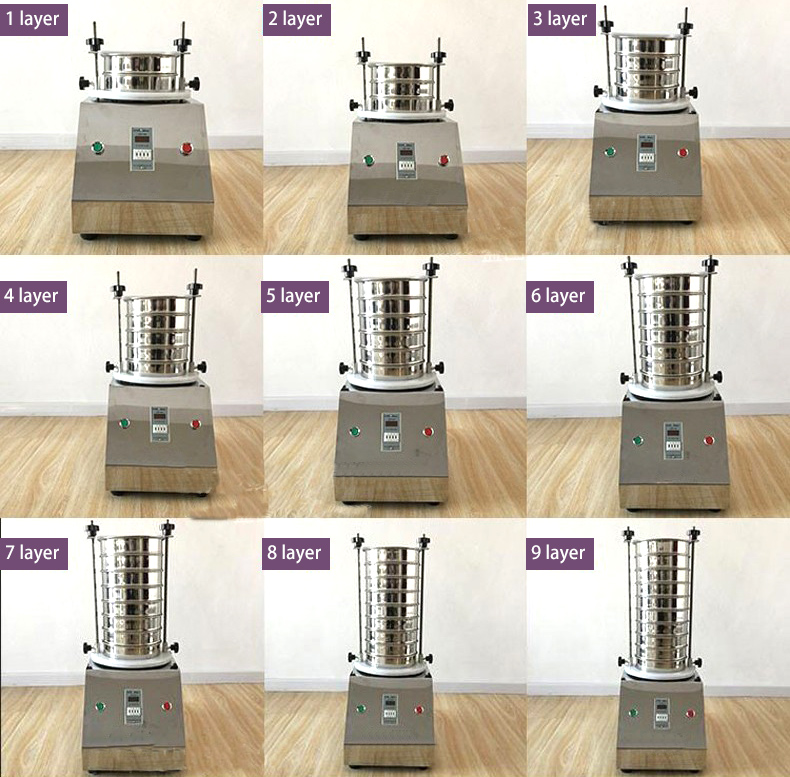

Sieve Stack: The sieve shaker usually accommodates multiple sieve screens stacked on top of each other. Each sieve screen has a specific mesh size to allow particles of a certain size to pass through.

Material Loading: The material to be sieved is placed on the top sieve screen of the stack.

Separation Process: As the vibrating sieve shaker vibrates, the particles in the material move across the sieve screens. Smaller particles pass through the mesh of the sieve screens, while larger particles are retained on the screens.

Analysis: After the sieving process is complete, the retained particles on each sieve screen are collected and analyzed to determine the particle size distribution of the material.

| No. | name | unit | parameter |

| 01 | frame | the number of layer | 1-8 |

| 02 | frame diameter | mm | &200 |

| 03 | sieve size | mm | 0.025-3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 2-500 |

| 06 | vibration frequency | times/min | 1440 |

| 07 | outside dimension | LWH | 350*350*(300+n*5) |

| 08 | power supply | V;HZ | 200;50 |

| 09 | machine weight | kg | 2-500 |

| 10 | vibration motor | power | o.12kw |

Stainless steel material

The screen frame is stretched and polished by SUS304 stainless steel, with a wall thickness of 0.6mm, uniform gloss, strong and durable, and non-magnetic

Standards compliant

The screen and the screen frame are fixed by soldering forming to prevent looseness and shaking, and meet the requirements of the national standard GB/T6003.1-1997.

Multi-level classification

It is equipped with 1-7 layers of test sieve, which can accurately separate a kind of granular material into 2-7 particle sections at the same time.

0-99 minutes timer

Equipped with time relay control, the screening time can be controlled freely, which can ensure the repeatability of the test.

Laboratory vibrating sieve shaker typically consists of the following components:

Sieves:A stack of sieves with varying mesh sizes, arranged in order of decreasing aperture. These sieves are typically made of metal or nylon.

Vibrating Mechanism: This mechanism generates the vibrations that cause the particles to pass through the sieves. It can be either electromagnetic or mechanical.

Base or Frame: A sturdy base or frame to support the sieves and vibrating mechanism.

Timer: A timer to control the duration of the sieving process.

Cover: A cover to enclose the shaker and prevent particles from escaping.

Pharmaceutical Industry: For particle size analysis of powders and granules used in drug formulations.

Food Industry: For quality control of food products like flour, sugar, and spices.

Chemical Industry: For analyzing particle size distribution of pigments, catalysts, and other chemical substances.

Mining and Metallurgy: For determining the size of minerals and ores.

Environmental Science: For studying the particle size of soil, sediments, and pollutants.

Construction Industry: For analyzing the particle size distribution of aggregates used in concrete and asphalt.

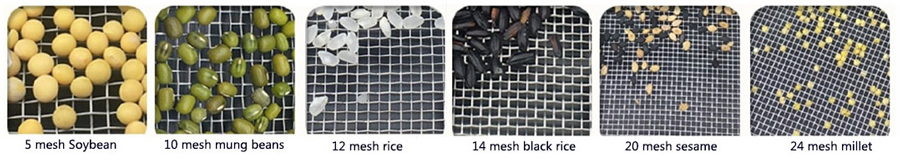

| Materials | Mesh | Materials | Mesh | Materials | Mesh |

| Oat kernels | 14 | Black beans | 5 | Barley | 8 |

| Buckwheat | 12 | Sesame | 24 | Medicinal powder | 60 |

| Corn flour | 30 | Almond powder | 40 | Flour | 50 |

| Whole grains | 40 | Coffee powder | 120 | Soy milk | 120 |

| Sichuan peppercorn | 6 | Chili seed | 10 | Pearl powder | 150 |

Vibrating sieve shakers are used in various industries, including pharmaceuticals, food processing, chemicals, and mining, where particle size analysis is crucial for quality control and product development. They offer a quick and efficient way to perform particle size analysis and ensure that materials meet the required specifications.

| Common mesh sizes and application examples: | ||

| Mesh size Mesh size (micrometers) | Application examples | |

| 20 Mesh | 850 | Preliminary screening of coarse particles |

| 40Mesh | 425 | Coarse screening of food and chemical raw materials |

| 60Mesh | 250 | Screening of pharmaceutical raw materials and fine powders |

| 80Mesh | 180 | Screening of fine powders |

| 100Mesh | 150 | Screening of ultrafine powders |

| 200Mesh | 75 | Screening of nanomaterials |

1. Determine the standard sieve to be selected according to the inspected material and the corresponding standard.

2. Stack the standard sieves on the tray according to the aperture from small to large, from bottom to top, and position the standard sieves by grooves or positioning screws.

3. Put the tested material into the standard sieve at the upper end, and cover the upper cover and pressing plate of the standard sieve. Then press the pressure plate with the round handle on the wire column, and tighten the round handle on the wire column to compress the standard screen. (Note that the force on both sides should be the same, and then tighten with the set screw.)

4. Adjust the timer switch to the corresponding required position. Then turn on the power switch, and the analytical sieve starts to work.

5. After the vibrating sieve shaker stops working, unscrew the round handle on the wire column, remove the upper cover and pressing plate, and carefully remove the standard sieve.

6. Cut off the power.

Dahan vibrating sieve shaker adopts the national standard GB/T6003.2-1997, which conforms to the international standard ISO3310-2:1990 R20/3, R20, R40/3 series.

Available from stock: Dahan is a direct-selling manufacturer, with sufficient product models in stock, and special model designs can also be supported.

Quality Assurance: 30-day refund for quality problems, the whole machine warranty period is 1 year, during which quality problems occur, our factory will provide maintenance services for free.

Fast delivery: standard parts stock in stock, 7 working days for special customization, fast delivery, guaranteed cycle.

Service guarantee: 7*24 hours of all-weather service response, clear reply within 1 hour, 72 hours on-site maintenance.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address::China,Yanjin county forest park gate to the west 1000 meters north road.