Providing optimal filtration of liquid substances, designed to efficiently filter aqueous applications and highly viscous substances, it can eliminate suspended and unwanted particles present in liquids.

![]()

![]()

Price:$420.00-$600.00/Set

Consult now and enjoy a 10% discount

Diameter: 450mm

Mesh size: within 400 mesh

Capacity: 400-1200 kg/h

Material: all stainless steel, stainless steel + carbon steel (the price will be cheaper than all stainless steel)

Customization: add valve at the discharge port, trolley type, heighten the screen frame, mobile type

Application: Capable of filtering liquid applications, such as soy milk, liquid chocolate, paint, syrup, paint, oil, etc. Paint is suitable for powder or slurry with less impurity content.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

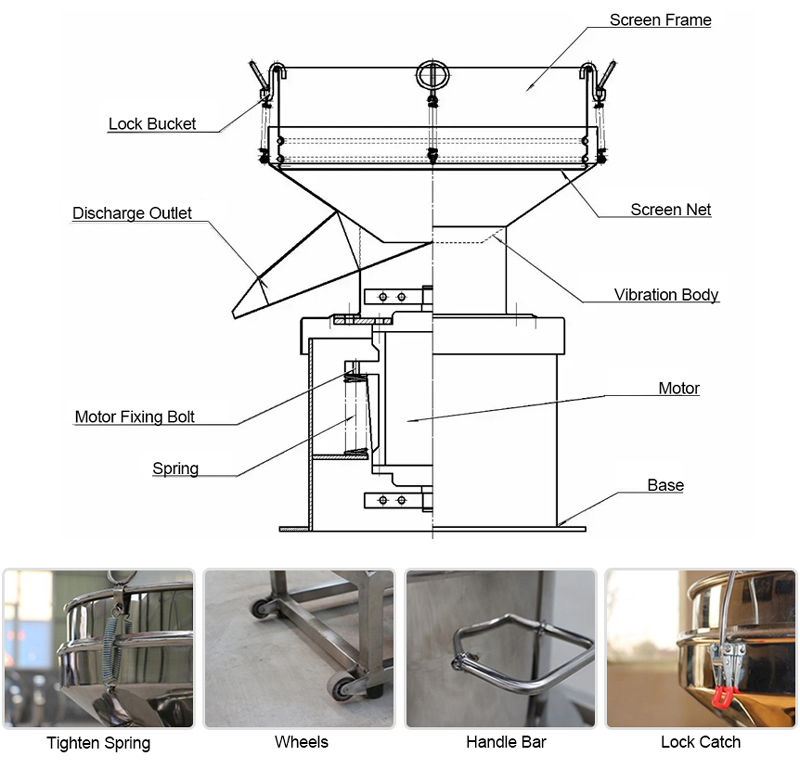

Vibrating filter, also called vibrating screen filter, is used to separate and filter solids from liquids or slurries. The working principle is to let the liquid or slurry mixture pass through a sieve or sieve vibrating at high frequency. The vibration separates the solid particles from the liquid and gathers them in the sieve surface while the liquid passes through the screen and collects in a separate container. Vibrating filters can be designed in different mesh sizes and materials to suit different applications, and can be used in a variety of industries, including food and beverage processing, pharmaceutical and chemical processing.

The main function of the vibrating filter is to separate and filter solid particles from liquid or slurry, which is achieved by passing the liquid or slurry mixture through a vibrating screen or sieve to separate the solid particles from the liquid. Has a variety of functions, including:

1. Solid separation: separate solid particles from liquid or slurry by vibrating sieve or sieve. Vibration separates the solid particles from the liquid and collects on the screen surface, while the liquid passes through the screen and is collected in a separate container.

2. Filtration: Can also be used to filter liquids or slurries, capturing any residual solid particles that may have passed through the screen.

| Application industry | Practical application | Application industry | Practical application |

| Food and Beverage Processing | Used to separate solids from liquids during the production of juices, sauces, soups and other food products. | Paints and coatings | Removes solid particles and impurities from paint and coating formulations. |

| Pharmaceutical processing | Used to separate and filter solids from liquid medicines, and in the production of vaccines and other pharmaceutical products. | Oil | To remove solid particles and impurities from crude oil and other oil and gas products. |

| Chemical processing | Used to separate and filter solids, including solvents, dyes and pigments, from liquid chemicals. | Water treatment | Used in water treatment plants to remove solid particles and impurities from wastewater and other liquids. |

The working principle of a vibrating filter involves the separation and filtration of solid particles from a liquid or slurry using a vibrating screen or sieve, usually made of wire mesh or other material with openings or pores of a specific size. The size of the openings or pores determines the size of the solid particles that can pass through the screen and be filtered from the liquid. When the liquid or slurry mixture passes through the vibrating screen, the solid particles are trapped on the screen surface and removed from the liquid. vibration

High separation efficiency

High-frequency vibration helps to efficiently separate solid particles from liquid or slurry with high separation efficiency.

Versatility

Can be designed in different mesh sizes and materials to suit different applications, making it a versatile solution for separating and filtering solid particles from liquids or slurries.

Safety

The motor is waterproof and dustproof, and the motor is equipped with a waterproof cover to prevent the motor from being exposed to water, and the safety can be guaranteed even if the liquid is filtered.

Low maintenance

The relatively simple design requires minimal maintenance or cleaning, making it a cost-effective solution for industrial applications.

Compact size

Compact in size, it can be easily integrated into existing production lines, thus saving space in production facilities.

Reduce waste

By separating and filtering solid particles from liquids or slurries, vibratory filtration helps reduce waste and improve the overall efficiency of industrial processes.

| Model | Power (kW) |

Whole machine size (mm) |

Sieve body size(Diameter*Height) (mm) |

Weight (kG) |

Description |

| DH-450 | 0.18 | 500*500*600 | 488*135 | 40 | The seat material is Q235 high quality carbon steel, stainless steel can be selected according to needs |

| DH-450s (With mobile trolley) |

500*500*1000 | 48 |

The vibrating filter can be customized to meet the specific needs of different industrial applications.

1. Stainless steel vibrating filter: It is specially designed for food, medicine, chemical industry and other industries for impurity removal, classification, solid-liquid separation, etc. It is made of 304 stainless steel or 316L stainless steel, and the inside and outside of the whole machine are polished. No welding seams, high cleanliness, easy to clean, can ensure that materials are not polluted during the screening process, and meet the hygienic requirements of the food and pharmaceutical industries.

2. Vibrating filter with valve: the amount of filtration can be controlled through the valve, and the filtration time can be extended by closing the valve, and the filtration accuracy of the product can be improved.

3. Vibrating filter with trolley: it is fixed on the trolley and can be moved at any time when needed. It is suitable for factories whose usage occasions change frequently.

| Product | Image | Mesh Size | Capacity |

| Soy Milk |  |

120 mesh,160 mesh | 1200 liters/hour |

| Flour |  |

30 mesh | 700 kg/h |

| Juice |  |

40 mesh-80 mesh | 6-10 m³/h |

| Lotion |  |

600 mesh | 1 ton/hour |

| Pomegranate juice (seed and juice separated) |  |

100 mesh | 5 tons/hour |

| Coating |  |

450 mesh | 800 liters/hour |

| Corn flour (flour, kernels separated) |  |

150 mesh | 200 kg/h |

| Spray paint |  |

325 mesh | 1200 liters/hour |

| Pigment |  |

100-200 mesh | 500 kg/h |

| Battery powder |  |

100 mesh,120 mesh | 600 kg/h |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.