304/316L stainless steel material, corrosion resistance, high temperature resistance, easy to clean, not easy to rust

![]()

![]()

![]()

Price:$530.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 100-1250mm

Conveying length: 4-45m

Output: 2.2-458m³/h

Applicable materials: flour, salt, monosodium glutamate, traditional Chinese medicine powder, western medicine powder, various feeds, etc.

Application: food, condiment, medicine, grain, feed, and other industries

Commitment:

Stainless steel auger conveyor is made of 304 or 316L stainless steel, which is resistant to acid and alkali corrosion, high temperature, and the spiral surface is not easy to rust after treatment, ensuring that the raw materials are contaminated and there is no residual material in the machine. , Suitable for applications that must strictly avoid any contamination of the processed materials and require absolute cleanliness and perfect corrosion resistance. Common applications include food, chemicals, drugs, and any other applications that require it for sanitation, corrosion or extreme temperature.

Stainless steel auger conveyor adopts SUS314 or 316L stainless steel screw conveyor, which has the characteristics of cleanliness, not easy to rust, acid and alkali corrosion resistance, high temperature resistance, etc. Corrosion-resistant applications, such as food production, feed processing, flour processing, pharmaceutical and chemical industries.

Conveying salt particles

Conveying sludge

Clean and hygienic

The stainless steel material is selected, and the whole machine has been polished inside and outside, so the stainless steel surface is smooth, free of burrs, high in cleanliness, and the conveyor will not rust, which meets the hygienic requirements of the food and pharmaceutical industries.

No pollution, easy to discharge and clean

The silo and conveying pipe are all made of stainless steel (the material can be 201, 301, 304, 316, 316L, 321 stainless steel, the material itself has wear resistance and corrosion resistance, the higher the nickel content, the higher the quality), ensuring Raw materials will not be contaminated.

Preservative

304 or 316L stainless steel, to avoid chemical reaction with acid and alkaline materials when conveying materials.

High temperature resistance

The working temperature is -20 degrees Celsius to 50 degrees Celsius, and it can transport powder, granules and small lump materials at 200 degrees Celsius.

Convenient nesting

There is a discharge valve at the lower end of the feed port, and the spiral can be reversed for discharge, so discharge and cleaning are very convenient.

Convey evenly

Small diameter and high rotating speed ensure smooth, fast and even delivery of products during the working process.

Stainless steel auger conveyor conveys the material along the displacement direction by the rotating spiral blade, which relies on the double force of the material's own gravity and the friction force of the screw conveyor casing on the material; and the displacement of the material in the middle bearing depends on The rear material is conveyed by the thrust of forward movement; the screw conveyor is equipped with a feed inlet and a driving device (reducer, motor) at one end, and a discharge port at the other end. When the machine is operating, the spiral blade pushes the material to move. In this movement, the weight of the material itself will friction with the groove wall to generate force, which will cause the material to move forward along the direction of the spiral blade grinding along with the rotation of the screw. For the spiral conveyor with a large inclination angle, the material is continuously poured into the pipe wall and blades, and the centrifugal force on the material is greater than its own gravity, and then it is pushed forward.

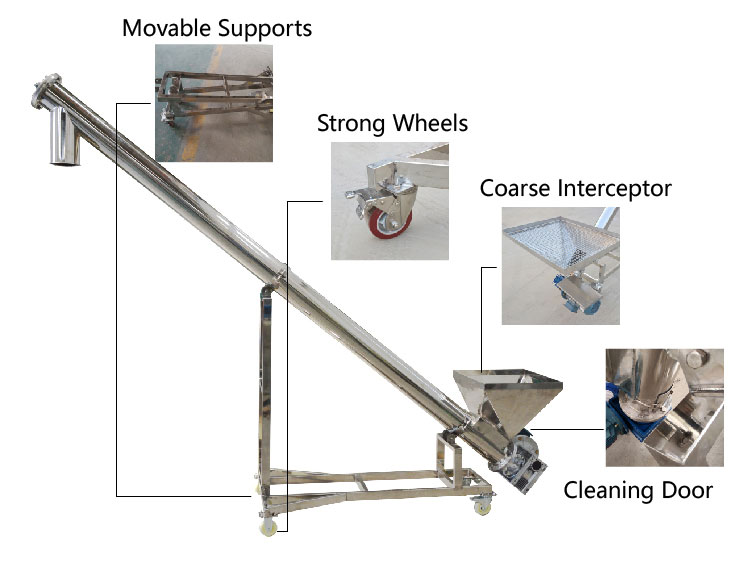

1. Feeding device: welded with angle steel and steel plate, connected with feeding equipment, at the upper part of the tail.

2. Head section: It is mainly composed of three parts: thrust bearing, spiral body, and casing. The thrust bearing is to bear the axial thrust when the material is conveyed. When using a helical gear reducer, the additional overhung load of the drive must also be taken at the same time.

3. Intermediate section: It mainly includes the hanging bearing, the spiral body and the casing. The hanging bearing supports the screw shaft, so that the stainless steel screw conveyor can work normally, which is an important part.

4. Driving device: It is composed of motor, reducer, coupling and other parts, and is the main component for the stable operation of the equipment.

6. Tail section: mainly consists of four parts: flat bearing, screw body, suspension bearing, and casing. The flat bearing can not only support the tail screw, but also be used to adjust the slight change in the axial length of the entire screw conveyor during installation.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| 304 and 316 stainless steel comparison | ||||

| Serial number comparison item | Comparison item | 304 | 316L | Remark |

| 1 | Price | Low | High | 304 stainless steel has excellent performance, low unit price, and is more widely used |

| 2 | Molybdenum content% | 0 | 2-3 | The higher the Mo content, the better the corrosion resistance and heat resistance |

| 3 | Nickel content% | 8-10.5 | 10-14 | The higher the Ni content, the better the corrosion resistance and heat resistance |

| 4 | Carbon content% | <0.08 | 0.03 | The higher the C content, the lower the C content, the better the welding performance |

| Note | 1: When we refer to 316 stainless steel, it refers to 316L stainless steel 2: Carbon is a strong austenite forming element, which can significantly increase the strength of steel, but the higher the carbon content in carbon steel, the worse the plasticity, and carbon also has an adverse effect on corrosion resistance |

|||

S tainless steel screw conveyor materials can be divided into 304, 316L two stainless steel materials.

The difference between 304 stainless steel and 316L stainless steel:

304 stainless steel can withstand high temperature of 800 ℃, has the characteristics of corrosion resistance, easy processing, and good toughness. When the requirements for corrosion resistance are not high, 304 stainless steel is better because the unit price of 304 stainless steel is lower than that of 316 stainless steel.

316L stainless steel is a material with a lower carbon content in the same series. Compared with 304, 316L stainless steel has stronger chemical corrosion resistance, and is more resistant to high temperature creep, stress fracture and tensile strength than other steels. When there are higher requirements for corrosion and heat resistance, 316 stainless steel is better.

Dahan stainless steel screw conveyor is preferably made of 304 and 316 stainless steel, and the thickness of the plate is controlled at 10mm. The equipment has better wear resistance and long service life. The Dahan manufacturer has also obtained ISO\CE certification. Guarantee higher product quality.

The stainless steel screw conveyor can withstand high temperature of 200 ℃, resist the erosion of acid and alkaline materials in special industries, and can ensure that the materials will not be polluted during the transportation process, and meet the high standards of hygiene in the food and pharmaceutical industries. The hourly transportation volume can reach 134 Cubic / hour, can be arranged horizontally or inclined, and can also be designed according to user requirements, and the conveying distance is longer.

Dahan stainless steel screw conveyor adopts a lower direct selling price, and the manufacturer and the user realize one-to-one communication, which reduces the link of middlemen, not only can reduce the circulation cost, but also can understand the actual situation of the user more directly, and reduce the need for the user to choose Trouble in the process and avoid unnecessary waste.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.