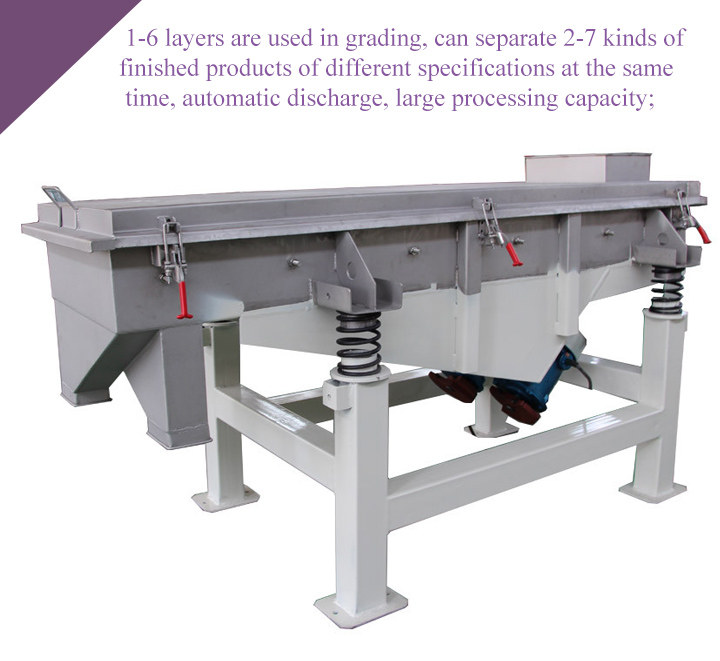

The carbon steel linear vibrating screen is made of Q235 carbon steel, which is more common and is generally used in industries that do not have strict hygiene requirements and has low cost. Suitable for up to 400 meshes, it adopts a multi-layer fully enclosed structure design and multiple discharge ports. The screened materials can be divided into multiple levels according to the size and granularity. The material is automatically discharged and the output is large.

1. Carbon steel has low strength and hardness, high plasticity and toughness, good welding performance, good forge and stampability, low cost and wide performance range.

2. Sieve to 400 mesh, suitable for non-viscous dry powder or granular materials.

3. The accuracy rate of screening and classification is over 96%, and the screening efficiency is high.

4. 1-6 layers of screen frame can be used, 2-7 kinds of finished products of different specifications can be separated at the same time, automatic discharge, and large processing capacity.

5. The fully enclosed structure can effectively prevent dust pollution and material leakage during the screening process.

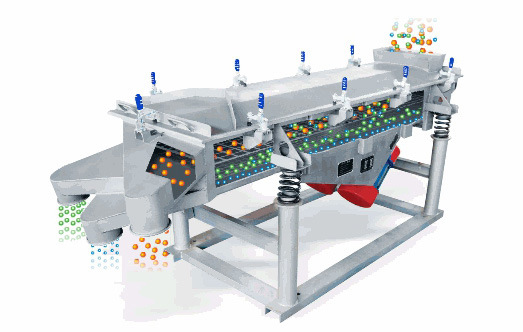

The carbon steel linear vibrating screen uses two vibrating motors to rotate in the opposite direction, so that the exciter generates a reverse excitation force, and drives the screen box to move back and forth linearly. When the material enters the screen box from the inlet at one end, it is evenly distributed on the screen. On the surface, under the combined force of the exciting force and the weight of the material, the material is thrown up on the screen surface and jumps forward to the discharge port. Finally, the material is screened and screened through various layers of screens with different apertures. For classification, the materials are discharged from the corresponding outlet of each layer, thus completing the entire screening process.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Food industry: soybeans, chestnuts, steamed buns, spices, powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.;

Chemical industry: fertilizer, urea, petroleum coke, resin, coating, cosmetics, paint, etc.;

Pharmaceutical industry: industrial medicines, Chinese medicine powder, granular pills, pellets, etc.;

Metallurgical industry: aluminum powder, lead powder, copper powder, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand ,Wait;

Other industries: plastics, abrasives, waste oil, wastewater, dyeing and finishing wastewater, papermaking, additives, activated carbon, carbon, building materials, etc.

| Material | Specific Gravity | Mesh | Capacity KG/H |

Model |

| Quartz sand | 1.6 | 70 mesh | 30000 | DZSF-1540-3s |

| Sunflower seeds | 0.04 | 80 mesh | 7100 | DZSF-525-1s |

| Plastic particles | 0.95 | 3 mm | 500 | DZSF-515-2s |

| Iron ore powder | 2.3 | 150 mesh | 10000 | DZSF-1020-3s |

| Slag | 4 | 5 mm | 10000 | DZSF-1020-1s |

| Sawdust | 0.2 | 80 mesh | 18000 | DZSF-1030-3S |

| Emery | 4 | 60 mesh | 300 | DZSF-515-1S |

| Wood flour | 0.4 | 120 mesh | 2000 | DZSF-1036-4s |

| Activated carbon | 0.8 | 36 mesh | 500 | DZSF-515-1s |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.