Conveying systems designed specifically for conveying sand or other granular materials.

![]()

![]()

Price:$300.00-$5,000.00/Set

Consult now and enjoy a 10% discount

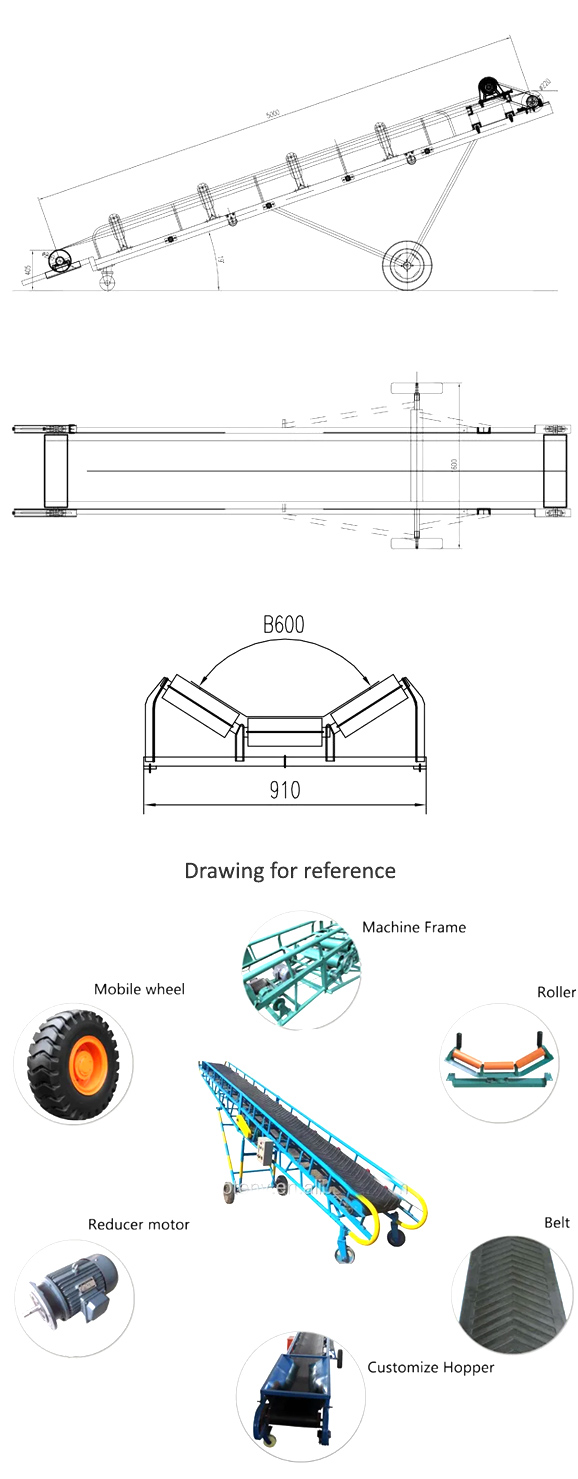

Belt Width: 400/500/650/600/800/1000/1200/1500mm

Conveying length: 10-30 meters

Conveying capacity: 30-3000t/h

Conveying speed: 1.25-2.0m/s

Voltage: 380V

Power: 0.4kW - 22kW

Application: Can be used for a variety of applications, from loading and unloading trucks to transferring sand between different stages of processing.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Sand belt conveyor is a type of conveyor system used to transport sand or other granular materials. It is specifically designed to handle the challenges associated with moving bulk materials like sand efficiently and effectively.These conveyors are commonly used in industries such as mining, construction, agriculture, and foundries, where the transportation of sand is a crucial part of the production process. They offer advantages such as efficient material handling, reduced labor requirements, and increased productivity.

The conveyor system is designed with features to prevent spillage and ensure the smooth movement of sand. The belt is often textured or patterned to offer grip and prevent the material from slipping during transportation. Side skirts or containment systems may be incorporated to contain the sand and minimize dust or spillage.

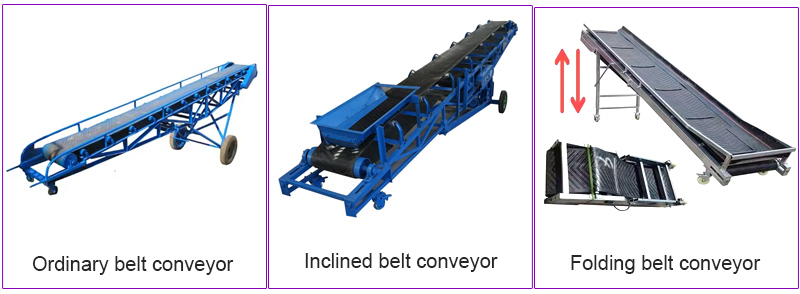

Several common belt conveyor types used in sand conveying applications include:

1. Ordinary belt conveyor: This is the most common type, consisting of a continuous belt of rubber or PVC material. It is suitable for small and medium-sized sand transportation and can be transported horizontally or slightly inclined.

2. Inclined belt conveyor: This type of conveyor has an obliquely inclined conveyor belt, which can be used to transport sand from a low place to a high place, or from a high place to a low place. It is often used in the process of stacking and unloading materials, which can save manual labor and improve efficiency.

3. Folding belt conveyor: This type of conveyor usually consists of multiple foldable segments, allowing it to be adjusted between different lengths and heights. It is suitable for situations where rapid adjustment and layout are required according to site needs.

Sand belt conveyors play an important role in various industrial fields and application scenarios. The following are the application scenarios of sand belt conveyors:

Mining industry: Sand belt conveyors are widely used in mines to transport bulk materials such as coal, ore, gravel, etc. from mining sites to processing plants or shipping docks.

Construction sites: On construction sites, sand belt conveyors are used to transport cement, sand, concrete and other materials.

Ports and terminals: Sand belt conveyors are widely used in ports and terminals for loading and unloading bulk cargo from ships, such as coal, ore, grain, etc.

Metallurgical industry: In the metallurgical industry, sand belt conveyors are used to transport raw materials such as ore, coke, limestone, etc.

Concrete production: Used to transport raw materials such as sand and stone to concrete mixing stations to produce concrete.

Efficient Material Handling

Sand belt conveyors offer a reliable and efficient means of transporting bulk materials, reducing the need for manual labor and increasing productivity.

Minimized Material Loss

The enclosed design of sand belt conveyors helps prevent material spillage and loss during transportation, ensuring the integrity of the transported materials.

Wear resistance

The conveyor belts of belt conveyors are usually made of wear-resistant materials, which can resist the wear of granular materials such as sand and extend their service life.

High capacity

Belt conveyors can efficiently transport large amounts of sand and are suitable for scenarios requiring large-scale material transportation.

Reduced Labor Costs

By automating the transportation process, sand belt conveyors help businesses save on labor costs and improve overall operational efficiency.

Dust Containment

Sand belt conveyors may be equipped with dust containment systems to minimize the release of dust particles into the surrounding environment.

Different conveyor belt materials: Belt conveyors use conveyor belts made of flexible materials such as rubber, PVC, and PU; plate conveyors use conveyor plates made of rigid materials such as metal plates and plastic plates.

Different conveying methods: Belt conveyors convey materials through the continuous movement of conveyor belts; plate conveyors convey materials by driving chain plates or rollers to drive conveyor plates to move.

Different application scope: Belt conveyors are suitable for conveying bulk materials, block materials, bagged materials, etc., and have a wide range of applications; plate conveyors are more suitable for conveying items with regular shapes, such as bottles, cans, boxed items, etc.

Different conveying speeds: Belt conveyors have faster conveying speeds and can achieve high-speed continuous conveying; plate conveyors have relatively slow conveying speeds and are more suitable for low-speed conveying.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

Implementing dust control measures in sand belt conveyors is crucial to minimize airborne dust emissions and create a healthier and safer work environment. Here are some common methods for controlling dust in sand belt conveyors:

1.Enclosures and Covers: Install enclosures or covers along the conveyor system to contain the dust within the conveyor's enclosed space. These enclosures can be made of materials such as sheet metal or fabric and should be designed to prevent dust from escaping into the surrounding environment.

2.Dust Collection Systems: Install dust collection systems along the conveyor line to capture airborne dust particles. These systems typically consist of dust collectors, such as baghouses or cyclone separators, which use filters to trap and collect dust. The collected dust can then be disposed of or recycled appropriately.

3.Belt Cleaning Systems: Install belt cleaning systems to remove residual material from the conveyor belt surface. Belt scrapers or brushes can effectively remove excess sand and prevent it from becoming airborne. Regular maintenance and adjustment of these cleaning systems are essential to ensure their effectiveness.

4.Proper Belt Tension: Maintain the appropriate tension of the conveyor belt to avoid excessive slippage or material spillage, which can generate dust. Proper belt tension helps ensure efficient material transfer and minimizes the generation of airborne dust.

5.Material Moisture Control: Control the moisture content of the sand to minimize dust generation. In certain applications, adding water or moisture to the sand before it enters the conveyor system can help reduce dust emissions. However, it is important to strike a balance to prevent material handling issues or belt slippage due to excessive moisture.

Xinxiang Dahan is a professional belt conveyor manufacturer focusing on producing high-quality sand belt conveyors. They have advanced production equipment and technical teams dedicated to providing reliable and efficient conveying solutions. Xinxiang Dahan's sand belt conveyors are widely used in mining, construction, metallurgy, chemical and other industries, and are widely recognized by customers for their stability, durability and adaptability. They have earned a good reputation for high-quality products and professional services, and continue to provide customers with customized conveying solutions.

Belt conveyors are usually used to convey sand for the following reasons:

Prevent leakage: The skirt design of the belt conveyor can effectively prevent sand from splashing and leaking, keeping the conveying process clean and safe.

High conveying efficiency: Belt conveyors can achieve continuous and stable conveying of sand.

Strong adaptability: Belt conveyors are suitable for various scenarios, and can convey sand horizontally, inclined or vertically to adapt to different process requirements and site layouts.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.