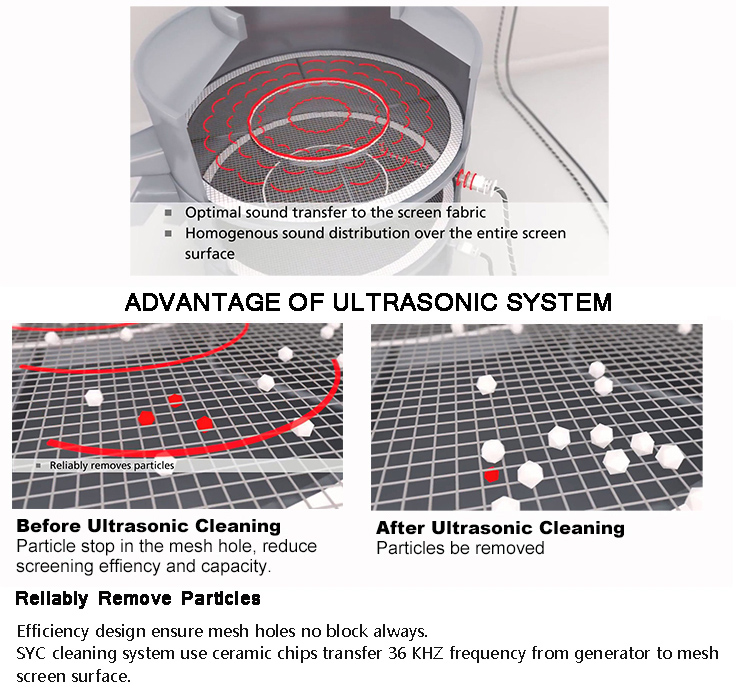

Utilizes ultrasonic technology to sift and separate food powders, preventing them from clogging the screen.

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-5000kg/h

Screen frame: 1-5 layers (3 layers is best)

Motor power: 0.25Kw to 2.2Kw or customized

Application: Designed to efficiently and accurately separate food powders such as flour, spices, sugar, cocoa powder, milk powder, whey powder, turmeric powder and pepper powder according to particle size.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Food powder ultrasonic sieving machine is designed to sieve food powders above 400 meshes, solve the screening problems such as blocking, sticking, and static electricity during screening of fine food powders, and remove large particles or foreign pollutants in food powders. To improve the quality of the finished product, ultrasonic frequencies are used to vibrate the mesh, which keeps the holes from clogging and makes it easier to screen powders, the system increases the screening capacity by a factor of 10, increasing productivity while allowing separation accuracy down to 20µm (# 635 mesh).

The food powder ultrasonic sieving machine used in the food industry needs to use the whole machine 304 stainless steel. This is to comply with the national food hygiene and safety, and not to destroy the material characteristics.

Food powder ultrasonic sieving machine is widely used in food powder. Here are some common applications of ultrasonic sieving machines in food powder handling:

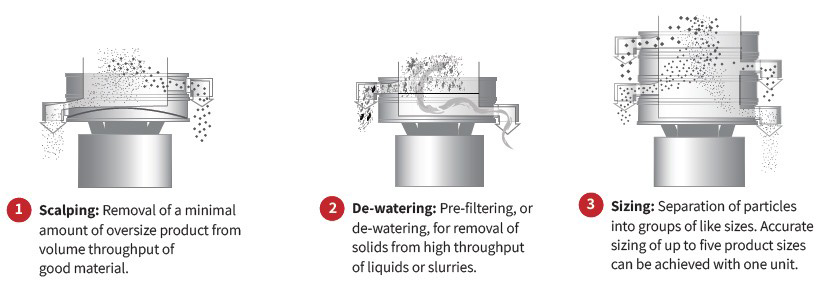

Screening and Classification: Can be used to screen and classify food powders according to particle size. It can effectively remove impurities and unqualified particles, ensuring the uniformity and quality of the powder.

Remove clumps: Food powders often form clumps during storage or transportation, affecting flow and uniformity. The vibration and ultrasonic action of the ultrasonic sieving machine can help break up and disperse the clumps, returning the powder to a free-flowing state.

Eliminate static electricity: Some food powders have electrostatic properties and are prone to sticking and clogging problems. The ultrasonic sieving machine's ultrasonic transmission can reduce electrostatic effects, prevent powder from adhering to the screen, and improve screening efficiency.

Removal of micro-particles: There may be micro-particles or fine impurities in some food powders, such as micro-dust, fibers, etc. The high-frequency vibration of the ultrasonic sieving machine can effectively separate these fine particles and improve the purity of the powder.

Food powder ultrasonic sieving machin employs ultrasonic technology to overcome the challenges associated with traditional sieving methods, particularly when dealing with fine powders that tend to clog or blind the screen. particularly when dealing with fine powders that tend to clog or blind the screen.

80-120 mesh: Commonly used for sieving food powders with large particles, such as coarse-grained seasonings, grain flour, etc. Commonly used in the production of seasonings, sieving all kinds of seasonings and removing impurities.

120-200 mesh: Suitable for sieving medium and fine particle size food powder, such as flour, milk powder, etc., commonly used in the flour milling industry, used for sieving large particles of impurities.

200-300 mesh: mainly used for sieving fine-grained food powder, such as powdered sugar, cocoa powder, etc., commonly used in food factories, bakery to ensure the fineness of the powder, improve the taste of baked goods.

Above 300 mesh: Used for sieving ultra-fine powder, such as some special functional food powder, used for sieving all kinds of powdered health care raw materials.

Note: The above mesh range is only a general reference, the specific mesh selection should be adjusted according to the actual situation.

High sieving accuracy

The ultrasonic vibrations enhance the sieving process by effectively separating fine particles and ensuring a high level of accuracy in particle size distribution.

Efficient and fast sieving

The ultrasonic energy helps to increase the throughput and sieving efficiency, allowing for higher production rates and faster processing of food powders.

Prevents mesh clogging

The ultrasonic vibrations prevent the food powder particles from sticking to the sieve mesh, reducing the chances of mesh clogging and ensuring continuous sieving operation.

Improved product quality

By achieving precise particle size control and reducing impurities, the ultrasonic sieving machine helps to improve the quality and consistency of food powders, resulting in better product performance and customer satisfaction.

Easy to clean and maintain

The machine is designed for easy cleaning and maintenance, with removable sieve frames and quick-release clamps, allowing for convenient access to the sieve mesh and reducing downtime during cleaning and maintenance procedures.

Versatile and customizable

Food powder ultrasonic sieving machine can be customized to meet specific requirements, including different mesh sizes, sieve decks, and configurations, making it suitable for a wide range of food powder applications.

| Model | Diameter (mm) |

Screening area (m2) |

Screen size target |

Layers | Input power (V/HZ) |

Ultrasound model |

Transducer location |

Frequency (KHz) |

Ultrasound gear |

Power (Kw) |

| DHC-200 | ⌀200 | 0.03 | 10-1200 | 1-5 | 220/50 | DHC-7 | External | 38KHz | Continuous 1-9 gears Pulse 2 gear |

0.18 |

| DHC-400 | ⌀340 | 0.09 | 1-3 | Sieving machine 380/50 Ultrasonic sieving machine220/50 |

Built-in/External | 0.25 | ||||

| DHC-600 | ⌀540 | 0.23 | 0.55 | |||||||

| DHC-800 | ⌀730 | 0.42 | 0.75 | |||||||

| DHC-1000 | ⌀900 | 0.64 | 60-635 | 1.1 | ||||||

| DHC-1200 | ⌀1100 | 0.95 | 1.5 | |||||||

| DHC-1500 | ⌀1400 | 1.54 | 2.2 | |||||||

| DHC-1800 | ⌀1700 | 2.27 | 3 |

| Materials | Use | Mesh size | Capacity |

| cocoa powder | Classification and removal of impurities | 100 mesh | 500 kg/h |

| spice powder | Improve flow and mixing uniformity | 80 mesh | 300 kg/h |

| protein powder | Solve the problem of powder clogging | 120 mesh | 800 kg/h |

| food coloring powder | wetting and dispersing | 200 mesh | 200 kg/h |

| yeast | Grading and improving product quality | 60 mesh | 400 kg/h |

The dust generated during the food powder screening process will pollute the environment and endanger the health of operators. The dust generated can be effectively collected by installing dust collectors or dust removal equipment to reduce the spread of dust in the environment. The following are some measures that can be used to deal with dust problems:

Address:China,Yanjin county forest park gate to the west 1000 meters north road.