Used to transport plastic bottles from one point to another within a production or processing facility

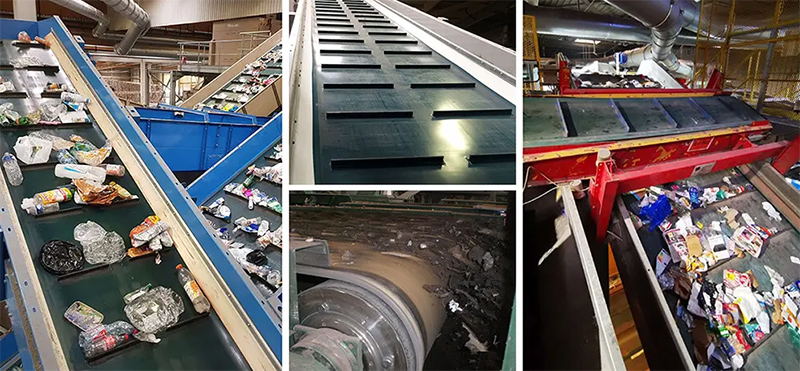

![]()

![]()

Price::$680.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Conveying angle: 0-90°

Belt width: 300-1500mm

Belt Type: Skirt

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Belt material: PVC, PU, rubber

Frame material: SUS304 stainless steel/carbon steel/aluminum

Weight: 300 kg

Application: Typically used in industries such as beverage manufacturing, recycling plants and packaging facilities where large volumes of plastic bottles are handled.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Plastic bottle belt conveyor is a type of conveyor system specifically designed for the transportation of plastic bottles in various industries, such as beverage production, bottling plants, and recycling facilities. It is commonly used to move plastic bottles between different stages of the production or recycling process, such as filling, capping, labeling, packaging, or sorting.

The plastic bottle belt conveyor is designed to securely hold and transport plastic bottles while minimizing the risk of damage or spills. It typically includes features such as side guides, adjustable rails, or cleats along the edges of the belt to ensure bottle stability and prevent tipping or falling.These conveyors can be customized to accommodate bottles of various sizes, shapes, and weights. The conveyor system can be adjusted in terms of width, length, and height to match the specific requirements of the application.

Plastic bottle belt conveyors are widely used, involving plastic bottle production, packaging, recycling and other industries. Here are some specific applications where plastic bottle belt conveyors are commonly used:

1. Beverage production: Plastics are used to transport empty bottles from the bottle depalletizer to the filling area. They ensure a smooth, continuous flow of bottles for an efficient filling, capping, labeling and packaging process.

2. Bottling plant: used to move the filled bottles from the filling station to the capping machine, labeling machine and packaging area. They help to automate the bottle handling process, increasing production speed and reducing manual labor.

3. Packaging and distribution: The bottles are transported to a packaging machine, such as shrink wrap or cartoning equipment, where the bottles are grouped, packaged, or boxed for shipping or display.

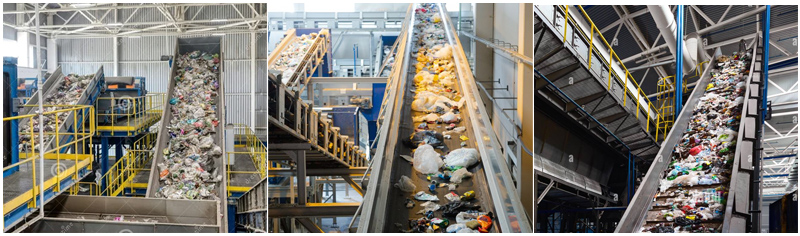

4. Recycling facilities: Plastic bottle belt conveyors are used in recycling facilities to transport and sort plastic bottles for recycling. They facilitate the movement of bottles through all stages of the recycling process, including sorting, shredding, washing and pelletizing.

Plastic bottle belt conveyor plays a vital role in modern industrial production, especially in the beverage, food, chemical and other industries. Its main functions are as follows:

1. Conveying: Bulk plastic bottles are continuously conveyed from one end of the production line to the other end. By controlling the speed and direction of the conveyor belt, the plastic bottles are conveyed in a specific direction.

2. Sorting function: By changing the speed, inclination or adding a separator, the plastic bottles of different specifications or types can be initially sorted.

Increased Efficiency

Plastic bottle belt conveyors automate the transportation process, eliminating the need for manual handling. This leads to increased efficiency and productivity as it allows for a continuous flow of plastic bottles. Workers can focus on other tasks, optimizing their time and resources.

Improved Throughput

By streamlining the movement of plastic bottles, belt conveyors enhance throughput in recycling operations. The conveyor systems can handle a large volume of bottles, ensuring a smooth and efficient recycling process. This results in higher productivity and faster processing times.

Gentle Handling

Plastic bottles can be fragile and prone to damage. Belt conveyors designed for plastic bottles incorporate features that ensure gentle handling. Adjustable speeds, cushioned belts, and transfer mechanisms minimize bottle breakage, reducing waste and improving overall product quality.

Versatility

Plastic bottle belt conveyors are versatile and can handle different sizes, shapes, and weights of plastic bottles. They can be customized to accommodate various bottle dimensions, ensuring a smooth and reliable conveying process regardless of bottle variations.

Adjustable Speed

Many plastic bottle belt conveyors come with adjustable speed settings to accommodate varying production requirements and prevent bottle breakage.

Automation Integration

Plastic bottle belt conveyors can be integrated with other automated systems such as fillers, cappers, labelers, and packers to create a seamless production line.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

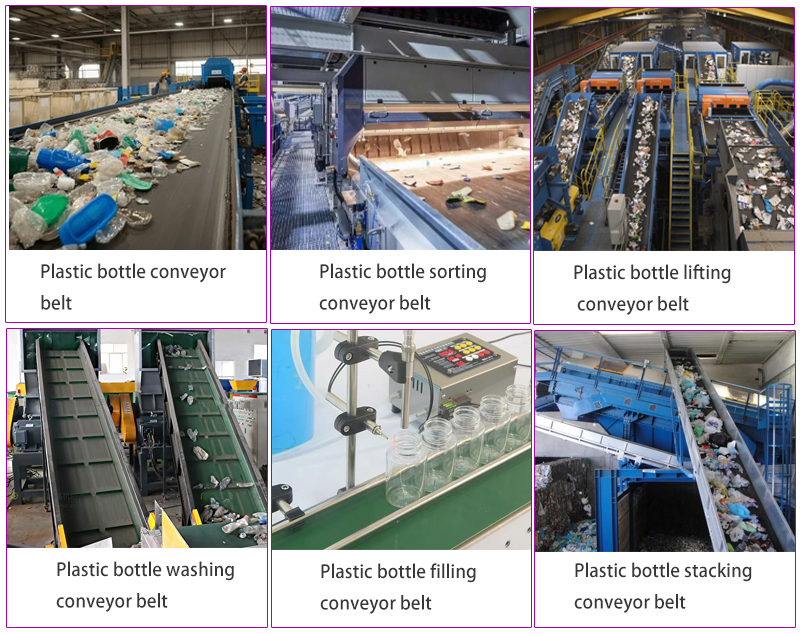

The types of plastic bottle belt conveyors can be classified according to their specific functions and uses. The following are several common types:

1. Plastic bottle conveyor belt: used to transport plastic bottles horizontally or obliquely in the production line. It has a simple design and is suitable for large-scale transportation, ensuring the stability of the bottles during transportation.

2. Plastic bottle sorting conveyor belt: used to automatically sort plastic bottles, suitable for recycling and logistics industries, suitable for PET bottle production, washing and recycling lines, bottle flakes washing and recycling line equipment, bottle flakes processing plants, film washing and recycling line equipment, bottle flakes crushers and other fields.

3. Plastic bottle lifting conveyor belt: used to transport plastic bottles between different heights.

4. Plastic bottle washing conveyor belt: used to wash plastic bottles, usually in combination with washing equipment.

5. Plastic bottle filling conveyor belt: usually used to transport empty bottles to the filling machine and convey the finished products after filling, with the bottle mouth facing up to ensure that the bottle mouth faces up during filling to prevent leakage.

6. Plastic bottle stacking conveyor belt: used to stack plastic bottles to a designated location.

Here are some key features and considerations related to plastic bottle belt conveyors:

Belt Type: Plastic bottle belt conveyors typically use a specialized belt made of plastic or rubber material that is durable, non-slip, and resistant to chemicals and moisture. The belt is designed to securely hold plastic bottles during transportation while minimizing the risk of damage or spills.

Bottle Orientation: Depending on the specific application, the belt conveyor may be designed to handle bottles in a specific orientation, such as upright or inverted. This ensures proper alignment and stability during transport.

Bottle Support and Stability: To prevent bottles from tipping or falling, plastic bottle conveyors often incorporate features such as side guides, adjustable rails, or cleats along the edges of the belt. These elements help to keep the bottles in a stable position throughout the conveyor's length.

Size and Configuration: Plastic bottle belt conveyors can be customized to accommodate bottles of various sizes, shapes, and weights. The conveyor system can be adjusted in terms of width, length, and height to match the specific requirements of the application. It is important to ensure that the conveyor is properly sized to handle the desired bottle capacity and production rate.

Sanitation and Hygiene: In industries such as food and beverage, cleanliness and hygiene are crucial. Plastic bottle belt conveyors are designed to be easily cleanable, with features such as wash-down components, smooth surfaces, and removable parts for maintenance and sanitation purposes.

Integration with Other Equipment: Plastic bottle belt conveyors can be integrated with other equipment or machinery, such as filling machines, capping machines, labeling systems, or sorting systems. This allows for seamless automation and improved production efficiency.

| Customer case | Convey products | Application occasions | Use | Conveying capacity |

| Beverage Manufacturer | Plastic Bottles | Beverage Production Line | Transport bottles between filling and capping stations | 10,000 bottles per hour |

| Recycling Facility | Recycled Plastic Bottles | Sorting and Processing Line | Move bottles for cleaning and shredding processes | 5,000 bottles per hour |

| Packaging Plant | Empty Plastic Bottles | Packaging Line | Convey bottles to the filling and labeling stations | 8,000 bottles per hour |

Xinxiang Dahan is a professional plastic bottle belt conveyor manufacturer. As a leader in the field, they are committed to providing customers with high-quality, reliable conveying solutions.

Xinxiang Dahan's plastic bottle belt conveyors are widely used in various industries, including plastic bottle recycling and reuse, plastic bottle production lines, plastic bottle packaging lines, and plastic bottle sorting and classification centers. Their conveyors are advanced in design, have efficient and stable conveying performance, and can meet the needs of different scenarios.

The company focuses on product quality and customer satisfaction, and they use high-quality materials and advanced production processes to ensure the durability and reliability of their conveyors. They also offer customized solutions, designing and manufacturing conveyors to customers' specific requirements to meet their unique application needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.