The palm oil filtration process is a very important process in the palm oil processing process. It refers to the removal of unwanted impurities in crude palm oil, such as fibers, sand, water, etc. The traditional manual filtration method is boiling, with palm oil With the development of processing industry, this method can no longer meet the requirements of modern palm oil factories. In order to speed up the efficiency and quality of palm oil filtration, it is necessary to use palm oil vibrating sieve to remove impurities or solid particles in palm oil.

Crude palm oil (CPO) and palm meal (PE) can be obtained from palm pulp through the process of boiling, crushing, and squeezing. At the same time, during the crushing process, the palm fruit (ie palm kernel) is separated, After crushing and removing the shell, the remaining kernels are extracted to obtain crude palm kernel oil (CPKO) and palm kernel meal (PKE). There are two different oils in the oil palm fruit. Palm oil is obtained from the pulp and Palm kernel oil is obtained from palm seeds (kernels), and the crude palm oil obtained after pressing contains impurities, which need to be filtered with filtering equipment, and clarified palm oil can be obtained after filtering.

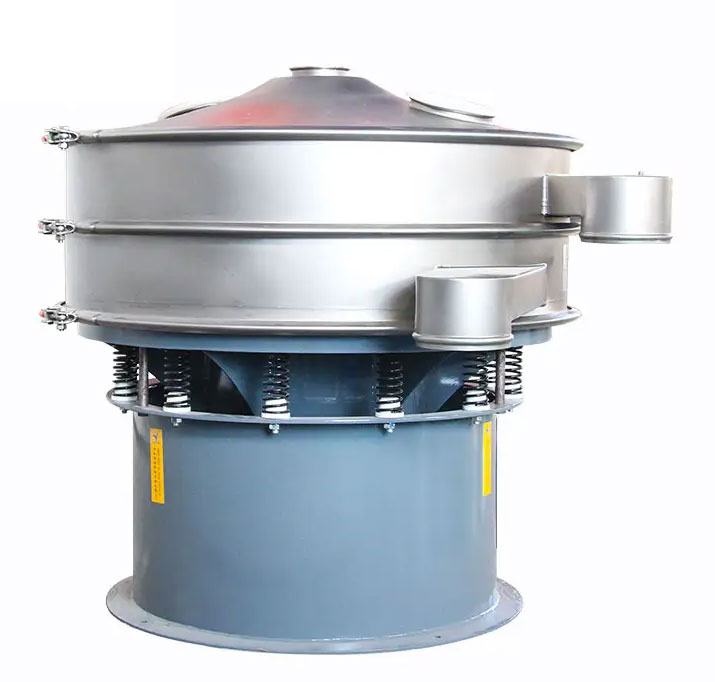

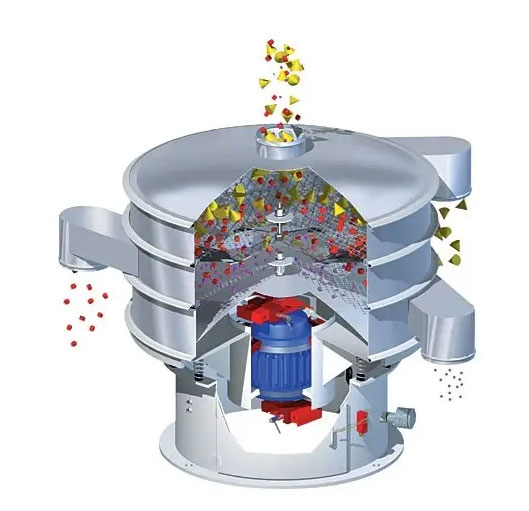

Feed the palm oil to be separated through the feed port (feed port at the top of the vibrating screen), make sure the cover plate, screen structure and base are fastened with snap rings, due to the unbalanced weight assembly, the vibrating motor will be energized, resulting in a vibrating motion , the sieve will start to vibrate, then the palm oil fed into the hopper will pass through the sieve according to the particle size, the material larger than the sieve size stays on the sieve surface and is discharged from the coarse material outlet, and the material smaller than the sieve size falls into the The lower layer, according to the design of the vibrating screen, you can configure 1-5 layers of screens to achieve particle size classification.

1. The machine can achieve high capacity on mesh sizes as low as 20 microns, ideal for minimizing handling costs and reducing product waste.

2. Impurities in palm oil can be quickly removed to obtain cleaner red palm oil, which is easier to store and has higher value.

3. All contact parts are made of high-quality stainless steel, which is easy to clean between batches.

4. The sieve frame adopts a heightened design to prevent palm oil from splashing out during the filtration process and will not waste products.

5. The body is seamlessly welded, and the sealing rings between the screen frames are tightly connected, which is more suitable for filtering palm oil

6. Mobile wheels can be installed at the bottom of the machine, which can move flexibly in the palm oil factory to cooperate with production.

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.