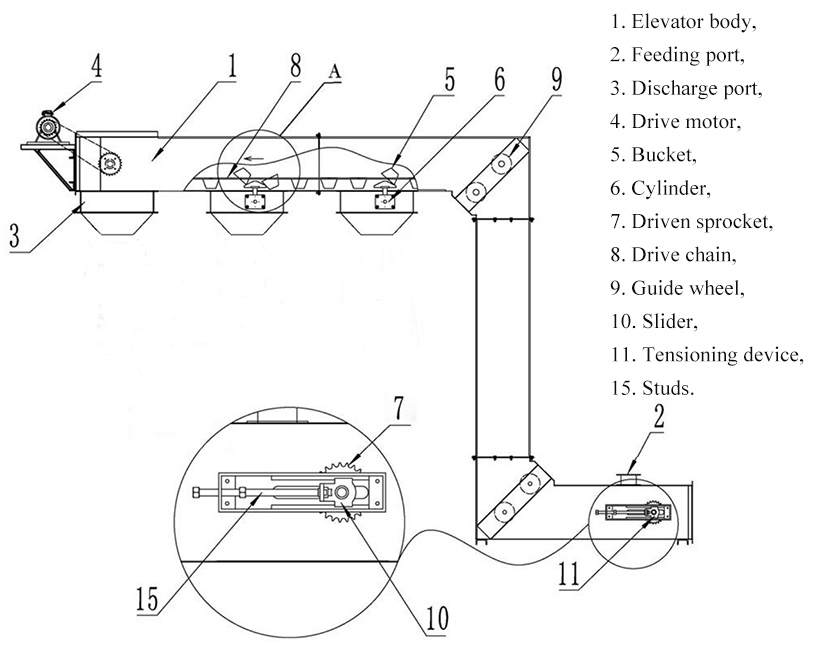

Z type bucket elevator is used for horizontal-vertical-horizontal combined conveying of powder, bulk particles or fragile products. However, everyone does not have sufficient understanding of its structure and principle. This article will explain the Z-type bucket elevator in detail for you. Structure diagram and working principle.

The Z type bucket elevator conveys the material through the hopper hung on the chain. As the chain is lifted to the top, it bypasses the upper wheel and then turns downward. The discharge device at the discharge port completes single-point or multi-point discharge (multiple Point unloading is not multi-point simultaneous unloading). In addition, Z-type bucket elevators are generally equipped with elevator shell plates to prevent dust from flying in the bucket elevator.

Watch a video below to learn more about its conveying and lifting principles:

Z type bucket elevator is mainly composed of casing, conveyor chain, hopper, driving wheel, diverting wheel, tensioning device, guiding device, feeding port, discharging port, etc.

Z type bucket elevator can choose different materials and configurations according to the lifting materials and user requirements.

1. Shell: semi-enclosed / dustproof / stainless steel or carbon steel sprayed shell.

2. Bucket material: SS304 stainless steel bucket/carbon steel bucket/food ABS or PP bucket.

3. Hopper capacity: 1.8L, 2.4L, 3.6L, 6L, 10L.

4. Drive device: explosion-proof geared motor/ordinary geared motor.

5. Sprocket: alloy steel sprocket/stainless steel sprocket.

6. Chain: alloy steel chain/stainless steel chain.

7. Control device: manual start and stop/automatic start and stop, frequency conversion control.

8. Feeding method of lifting conveyor: common hopper feeding/electromagnetic vibrating feeder.

9. Transmission voltage: 220V, 380V (single-phase or three-phase).

10. Bucket conveyor type: Z type, C type, single or multiple feed ports, single or multiple discharge ports.

The above is the working principle structure diagram and structural analysis of the Z-type bucket elevator. The Z type bucket elevator is very suitable for powder, bulk particles or fragile products. On the one hand, the Z-type bucket conveyor can pass single or multiple feeds mouth feed. On the other hand, the discharge can also be done through multiple discharge ports/outlets. , a hoist can meet the feeding of multiple silos.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.