A conveying system that uses a rotating screw to move bulk materials vertically or at an angle, mounted on wheels or casters for easy movement within a facility or from one location to another.

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 100mm-1250mm

Tilt angle: 0-60°

Hopper size: 100L

Conveying length: 1-20 meters

Conveying height: ≤3 meters

Motor power: 7.5KW-11KW

Optional material: carbon steel, stainless steel

Application: Commonly used in various industries, including agriculture, mining, food processing and construction. They are suitable for handling a variety of materials such as grains, powders, granules and bulk solids.

Commitment:

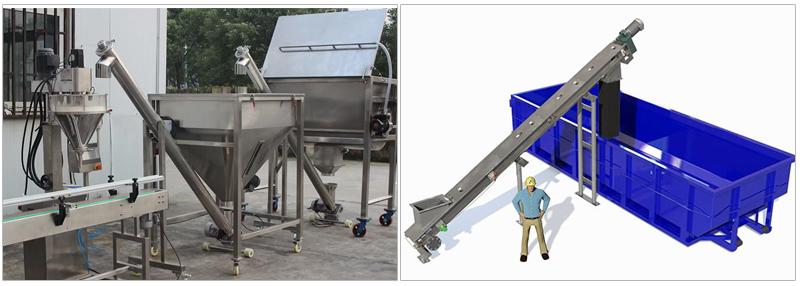

Mobile inclined screw conveyor is a type of screw conveyor that is designed to be easily movable and inclined for transporting materials at an angle. This type of conveyor is mounted on wheels or casters, allowing it to be easily relocated within a facility or from one location to another.

Mobile inclined screw conveyor can be used for horizontal, inclined or vertical conveying as required, and is suitable for various industrial fields, such as metallurgy, chemical industry, building materials, etc. Its mobility makes the equipment more flexible and applicable, and can meet the material conveying needs of different occasions.

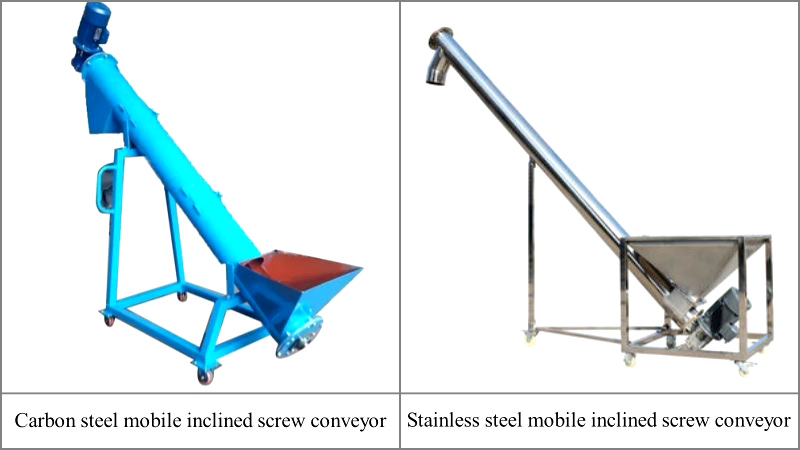

Mobile inclined screw conveyors can generally be divided into two types: carbon steel and stainless steel. These two types of mobile inclined screw conveyors differ in material and are suitable for different industrial environments and requirements:

Carbon steel mobile inclined screw conveyor: Carbon steel mobile inclined screw conveyor is usually made of carbon steel material, suitable for the conveying of granular materials in general industrial fields, with good strength and durability, and relatively low price.

Stainless steel mobile inclined screw conveyor: Stainless steel mobile inclined screw conveyor is made of stainless steel material, suitable for industries with high hygiene requirements, such as food, medicine and other fields, with corrosion resistance and easy cleaning characteristics.

Mobile inclined screw conveyors offer a convenient solution for transporting materials at an incline while providing the flexibility to move them to different locations as needed.

Construction Sites: Mobile inclined screw conveyors can be used at construction sites for transporting materials like cement, sand, and aggregates to different levels or areas.

Agricultural Facilities: In agriculture, these conveyors can be used for handling grains, seeds, fertilizers, and other agricultural products that need to be transported at an incline.

Warehousing and Logistics: They are useful in warehouses and logistics operations for efficiently moving goods and materials between different levels or areas.

Food Processing Industry: Mobile inclined screw conveyors are employed in the food processing industry for handling ingredients, powders, and other materials that require inclined transport.

Manufacturing Plants: These conveyors are used in manufacturing plants for transporting materials such as plastic granules, chemicals, and other bulk solids at an angle.

The working principle of the mobile inclined screw conveyor is to convey the material along the pipe or channel through the rotational movement of the screw. When the screw rotates, the material is pushed and moved along the conveying direction. During the movement, the material is pushed and stirred by the spiral blades, thereby achieving the conveying and mixing of the material. The rotation of the screw is driven by a transmission device, usually an electric motor or a hydraulic drive. The support frame and the bearing seat play the role of supporting and fixing the screw to ensure the stable operation of the equipment.

Mobility

The mobile design allows the conveyor to be easily moved to different locations within a facility, providing flexibility in material handling processes.

Inclined Transport

It is capable of transporting materials at an incline, making it suitable for applications where materials need to be lifted to different levels.

Adjustable Height

Some mobile inclined screw conveyors come with adjustable height features, allowing for customization based on the specific requirements of the application.

Versatility

These conveyors can handle a wide range of materials including powders, granules, and small bulk solids, making them versatile for various industries.

Compact Design

The compact design of mobile inclined screw conveyors makes them suitable for use in limited spaces or where space is a constraint.

Easy to Operate

They are typically easy to operate and can be quickly set up for material handling tasks.

| Model | Outer pipe diameter (mm) |

Screw Rotation Speed (r/min) |

Inclined angle (degree) |

Conveyor Length (m) |

| GX165 | 165 | 20,30,35,45,60,75,90,120,150,190,207,290 | <90 | 3~20 |

| GX219 | 219 | |||

| GX273 | 273 | |||

| GX325 | 325 |

In a mobile inclined screw conveyor, different inclination angles will affect the conveying efficiency and conveying method of materials. When selecting the inclination angle of the screw conveyor, it is necessary to consider the materials comprehensively. Our mobile inclined screw conveyor has the following angles

0-15°: Suitable for situations where the material requirements are not high and a small inclination is required, such as short-distance transportation with a slight inclination on a horizontal plane.

0-45°: Suitable for medium-inclination transportation, such as construction sites, mines, and other occasions where a certain inclination is required for transportation.

0-60°: Suitable for steeper material transportation, and can cope with some situations with large height differences or requiring fast transportation, such as in the mining industry.

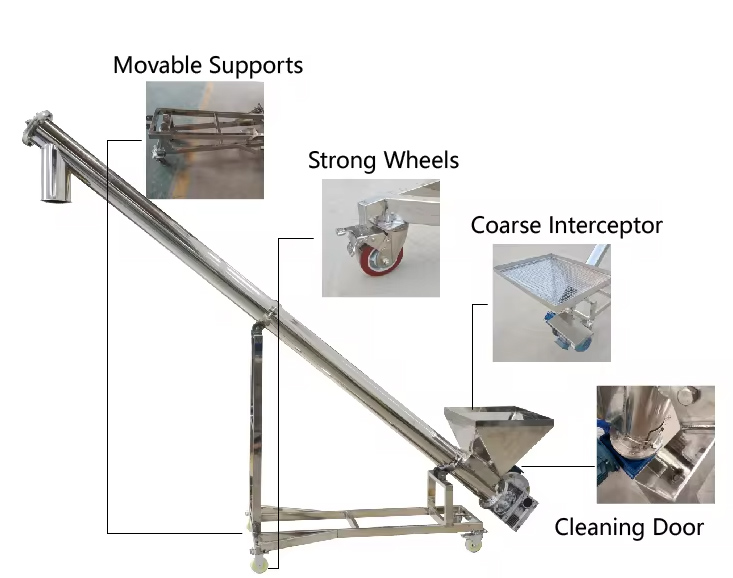

A mobile inclined screw conveyor is a versatile material handling equipment used to transport bulk materials vertically or at an incline. It consists of several key components that work together to facilitate the movement of materials. The following is a description of the typical structure of a mobile inclined screw conveyor:

1. Screw conveyor tube: Usually made of stainless steel or carbon steel. The tube serves as the outer shell of the screw and provides a containment space for the material being conveyed.

2. Incline angle adjustment mechanism: This mechanism allows the conveyor to be set to a specific angle to accommodate the desired incline or decline of the material flow.

3. Screw (auger): It is a spiral-shaped metal blade that rotates inside the conveying tube. The screw is responsible for moving bulk materials along the length of the conveyor. As the screw rotates, the material is pushed forward or upward depending on the incline angle.

4. Drive system: It usually consists of a motor, gearbox, and coupling. The motor converts electrical energy into mechanical energy and transmits it to the screw through the gearbox and coupling.

5. Hopper or inlet: The hopper is designed to facilitate a smooth and controlled flow of material into the screw. It may include features such as feeders, agitators, or vibrators to ensure proper material flow and prevent blockages.

6. Support structure and mobility: Mobile inclined screw conveyors are mounted on a support structure to provide stability and mobility. The support structure can be a frame or a set of legs with wheels or casters that allow the conveyor to be easily moved and positioned in different locations.

A chemical company introduced a mobile inclined screw conveyor to improve production efficiency. The equipment realizes fast and continuous conveying of granular materials on the production line, reducing manual handling and transportation time. Due to its flexibility, it can be conveyed horizontally, inclined or vertically according to production needs, greatly improving the adaptability of the production line. The mobile design makes the equipment easy to move and adjust, suitable for different production environments. By introducing a mobile inclined screw conveyor, the chemical company has achieved automation and efficiency in the production process, saving costs and improving production efficiency for the company.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.