Double-layer screen refers to a technology that uses two screens to screen materials.

![]()

![]()

![]()

Price:$860.00-$5,500.00/Set

Consult now and enjoy a 10% discount

Function:filter\separate\sort\sieve

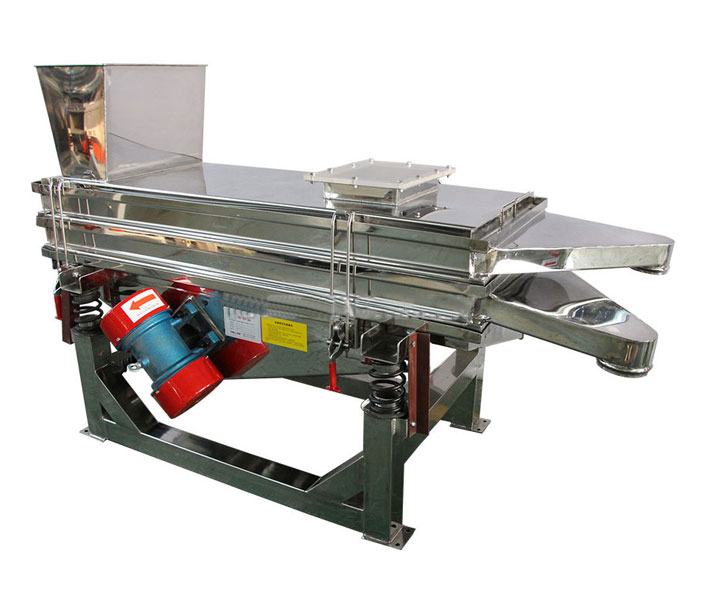

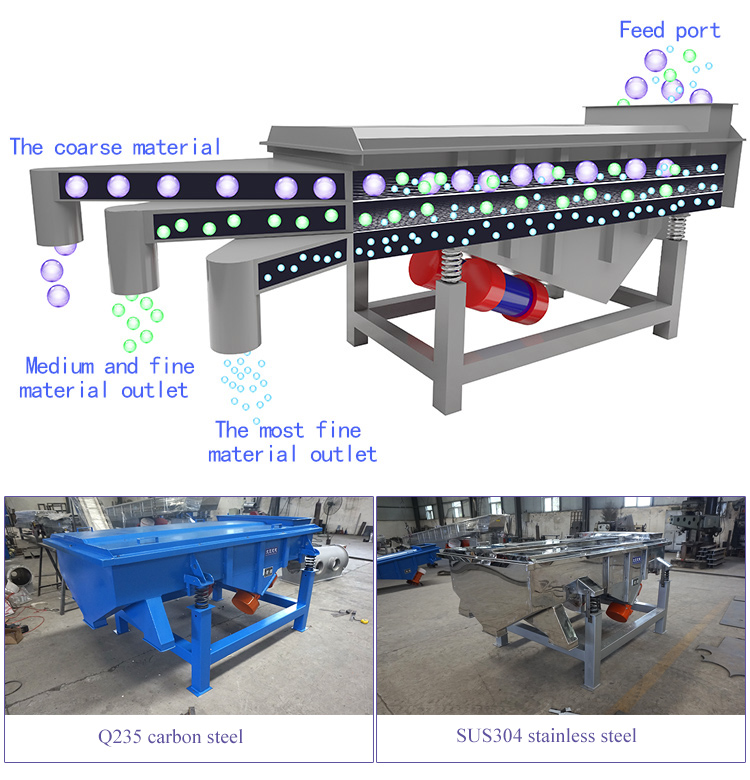

Material:Carbon Steel, Stainless Steel 304/316

Particle Size:0.074-10mm

Mesh Size:2-400 mesh Capacity:0.12-20t/h

Layers: 1-6 layers

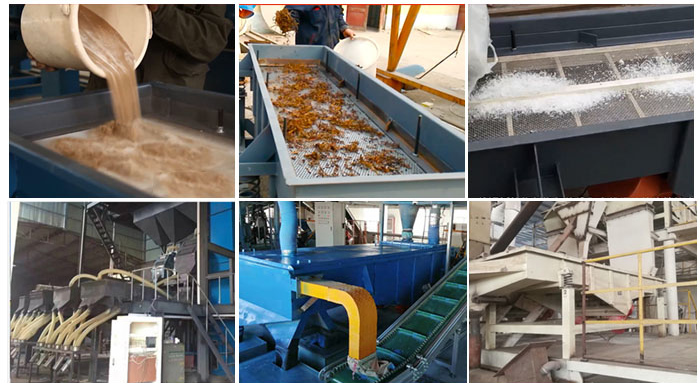

Application: Widely used in chemical industry, food, plastics, medicine, metallurgy, glass, building materials, food, fertilizer, abrasives, ceramics and other industries.

Commitment:

Double deck screen refers to a vibrating screen with 2 layers of sieve surface and 3 discharge ports. It can screen three kinds of materials or three kinds of precision of a single material, and the screening accuracy can reach more than 95%. It is suitable for powder, Grading of particles and removal of foreign bodies or particles from liquids.

Double deck screen is suitable for screening non-viscous dry powder and granular materials within 400 mesh. Its main functions are as follows:

1. Classification and screening: Divide solid particles into different particle groups of equal size. A single screen can accurately and continuously classify 3 different particle segments at the same time, which is suitable for the classification of granular and powdery materials in multiple industries.

2. Screening impurities: quickly remove large and small particles with low percentage content.

DAfter the material enters the double deck screen from the feeding port, it moves in a circular motion, and the material spreads from the center to the surrounding. Through the screen, it falls to the lower layer and the last layer, and is discharged from the corresponding discharge port to complete the screening work.

1. Two-layer screens can pass the bulk mixtures of different particle sizes through the sieve holes of the two-layer screen, and divide them into 3 different particle size products according to their particle size.

2. It can sieving 400 mesh dry powder or granules, and the sieving accuracy can reach more than 96%.

3. Driven by dual motors, the processing capacity can reach 0.12-20 tons per hour, which can be used for assembly line production.

4. Fully enclosed structure, no dust, prevent pollution and reduce noise at the same time;

Plastic pellet double deck screen

Stone powder double deck screen

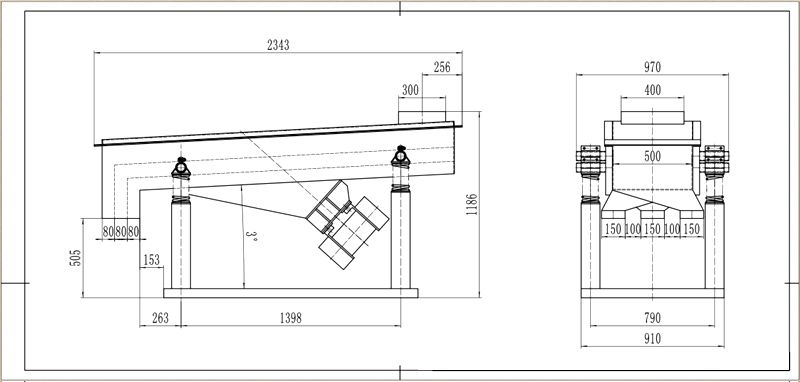

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.