Ideal for short term jobs involving moving dry soil, aggregate, sand, gravel, wet slurries and dirt.

![]()

![]()

![]()

Price:$750.00-$3,960.00/Set

Consult now and enjoy a 10% discount

Belt width: 300-1500mm

Conveying angle: 0-30°

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Frame material: SUS304 stainless steel/carbon steel/aluminum

Application: Used to transport materials such as soil, sand, gravel, mud, etc. from one location to another in construction sites, mines, agriculture and other on-site environments.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

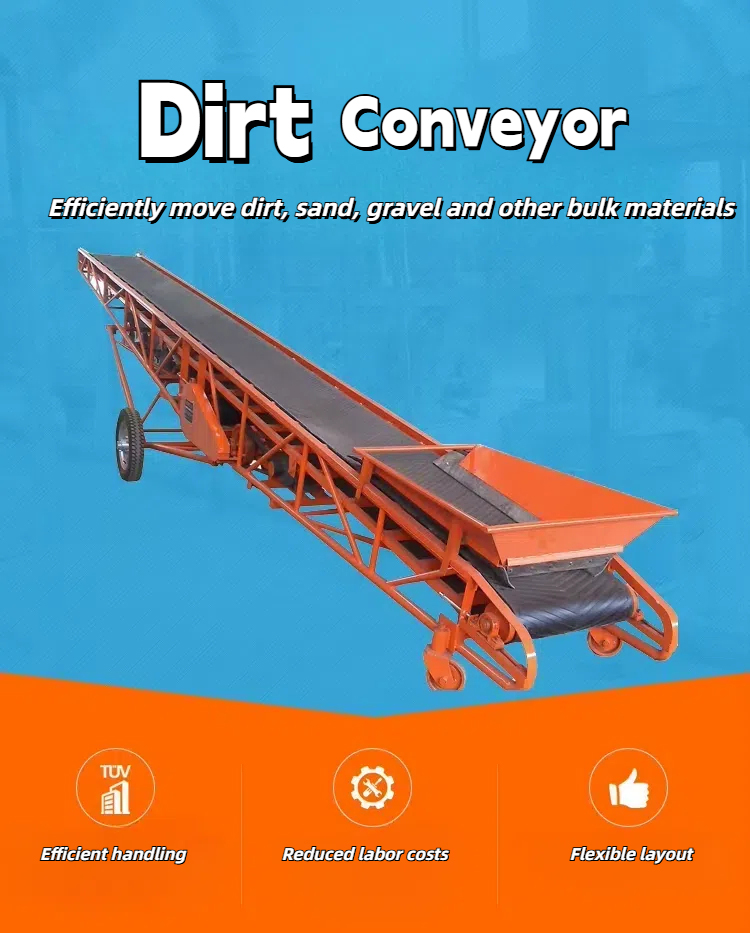

Dirt conveyor is a type of conveyor system that is used to transport dirt, soil, or other materials from one location to another. Dirt conveyors are commonly used in construction, excavation, and landscaping projects, where large quantities of dirt or soil need to be moved quickly and efficiently.Dirt conveyors can be customized to meet the specific needs of a project. For example, they can be designed in different lengths, widths and slopes to suit different types of terrain or materials.

Dirt conveyors play a crucial role in these projects by improving productivity and reducing labor costs. By using a dirt conveyor, workers can transport large quantities of dirt or soil with minimal effort, allowing them to focus on other tasks. Dirt conveyors also help to reduce the risk of injury and fatigue, as workers do not have to manually move heavy loads of dirt or soil.In addition to improving productivity and reducing labor costs, dirt conveyors also help to maintain the quality of the soil or dirt being transported. By using a conveyor, the soil or dirt is less likely to become contaminated with debris or other materials, ensuring that it remains suitable for use in the project.

There are many types of dirt conveyors to choose from, each with its own unique features and benefits. Here are some common types of dirt conveyors:

Dirt Screw Conveyor

Use a shaftless rotating screw or auger to move dirt or other materials. They are usually used in applications that require horizontal or inclined movement of materials. There is no central shaft, which prevents the transfer of viscous dirt from accumulation, clogging, and higher efficiency.

Dirt Conveyor Belt

Using a continuous belt loop to convey dirt or other materials, it can be used in a variety of applications and can be customized in different belt materials, widths and lengths to meet the specific needs of a project.

The function of a dirt conveyor is to transport large quantities of dirt, soil or other materials from one location to another in a fast and efficient manner. Its key function is to increase productivity and reduce labor costs. By using a conveyor, workers can easily transport large quantities of dirt or soil, freeing them to focus on other tasks. Dirt conveyors also help reduce the risk of injury and fatigue because workers do not have to manually move heavy objects or soil.

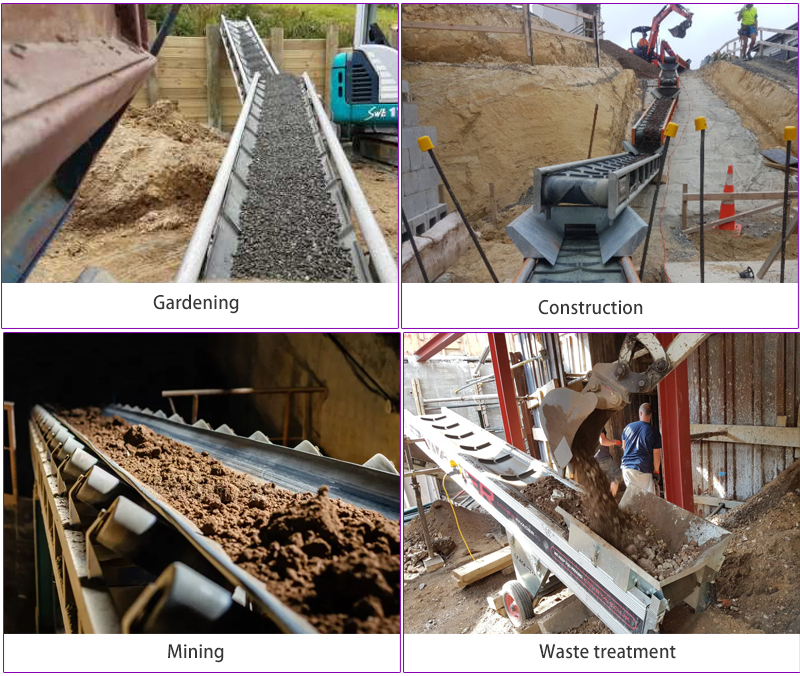

Here are some examples of applications where dirt conveyors are commonly used:

Construction: Transporting dirt, soil, or other materials from one location to another. They can be used to move material up and down steep grades, over long distances or around obstacles.

Excavation: Moving soil, gravel, or other materials away from an excavation site. They can be used to move material up and out of digging, reducing the need for manual labor.

Landscaping: Often used in landscaping projects to transport soil, mulch, or other materials to different areas of the site. They can be used to move material up and down slopes, over difficult terrain or around obstacles.

Agriculture: Used in farming to transport soil, fertilizer or other materials to different areas of the farm. They can be used to move material up and down slopes, over long distances or around obstacles.

Mining: Used to move soil, rock or other materials away from an excavation site. They can be used to move material out of mines, reducing the need for manual labor.

Improved Efficiency and Productivity

Minimized the need for labor, resulting in significant cost savings. Much faster than traditional methods such as trolleys, thus accelerating project schedules.

Versatility and Adaptability

Many dirt conveyors are portable and can be easily transported and installed in different locations. They can be adjusted to a variety of angles to suit different terrains and project requirements.

Enhanced Safety

By reducing manual handling, the risk of manual handling injuries that may occur when moving heavy materials can be reduced, improving workplace safety.

Environmental Benefits

By using conveyors, the need for heavy machinery and vehicles when moving materials on site can be reduced, thereby reducing the impact on the environment.

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| Dirt type | Main uses | Application scenarios | Recommended conveyors |

| Soil | Horticulture, agriculture, construction | Landscaping, agricultural planting, earthwork | Belt conveyors, screw conveyors |

| Soil improvement, soil screening | Vibrating conveyors | ||

| Mud | Construction, ceramics, chemicals | Concrete mixing, ceramic production, sludge treatment | Scraper conveyors, screw conveyors |

| Slag | Metal smelting, building materials | Steel smelting, cement production | Belt conveyors, bucket elevators |

| Dust-like minerals | Mining, chemicals | Ore crushing, powder material transportation | Screw conveyors |

| Wet minerals | Mining, chemicals | Ore washing, slurry transportation | Scraper conveyors, chain conveyors |

Selection suggestions

Material characteristics: Consider the particle size, density, viscosity, abrasiveness, temperature, etc. of the material.

Conveying capacity: Determine the conveying capacity according to production needs.

Conveying distance and height: Determine the length and vertical height of the conveying path.

Working environment: Consider the temperature, humidity, corrosiveness, etc. of the working environment.

Cost budget: Select a suitable conveyor according to the budget.

For custom soil conveyors, the following are some of the main special designs:

Flat Rubber Conveyor Belts: This type of conveyor belt is suitable for horizontal or slightly inclined dirt conveying, providing a smooth surface for easy dirt transfer.

Cleated Rubber Conveyor Belts: Conveyor belts with baffles prevent dirt from moving or spilling during transportation, suitable for occasions where dirt needs to be conveyed in an inclined or vertical direction.

Chevron Rubber Conveyor Belts: The herringbone texture conveyor belt design can provide better grip and is suitable for conveying dirt on slopes or inclined sites.

Oil-Resistant Rubber Conveyor Belts: This type of conveyor belt is suitable for use in environments where oil contamination needs to be prevented, and can effectively resist damage to the conveyor belt by oil substances.

Steel Cord Rubber Conveyor Belts: Conveyor belts reinforced by steel cords have higher tensile strength and wear resistance, suitable for handling heavy dirt and using under high load conditions.

Heat-Resistant Rubber Conveyor Belts: Heat-resistant conveyor belts can work in high temperature environments without being damaged. They are suitable for situations where dirt needs to be transported under high temperature conditions.

There are many customer stories and testimonials about the benefits of using dirt conveyors in various industries and applications. Here are a few examples:

Construction: A construction company in California used a dirt conveyor to transport soil and debris from a building site to a truck for removal. The company reported that the conveyor significantly improved productivity and reduced labor costs, allowing workers to focus on other tasks.

Excavation: A mining company in Nevada used a dirt conveyor to transport rocks and soil from an excavation site to a processing plant. The company reported that the conveyor reduced the need for manual labor and improved efficiency, allowing them to process materials more quickly.

Landscaping: A landscaping company in Florida used a dirt conveyor to transport soil and mulch from a delivery truck to different areas of a project site. The company reported that the conveyor significantly reduced the time and labor required to move materials, improving productivity and reducing costs.

Agriculture: A farm in Iowa used a dirt conveyor to transport soil and fertilizer from a storage area to different areas of the farm. The farm reported that the conveyor significantly reduced the need for manual labor, allowing workers to focus on other tasks.

Dahan Dirt Conveyor manufacturer provides one-stop service from design, drawing, modeling, processing, quality inspection, assembly, test machine, painting, delivery, etc. It has processing equipment such as bending machine, cutting machine, polishing machine and assembly workshop, Painting workshops, warehouses and other processing workshops. In addition, we also select and design according to the parameters you provide. We have 12 years of experience in design and production, and the product quality is good.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address:China,Yanjin county forest park gate to the west 1000 meters north road.