silica grain suction machine is a specialized equipment used in industries such as construction, foundries, glass manufacturing, and silica processing plants for the efficient handling and transportation of silica grains. Silica grains, also known as silica sand or quartz sand, are widely used in various industrial applications due to their high purity, heat resistance, and abrasive properties. Here is a detailed exploration of the silica grain suction machine:

Material Handling: The silica grain suction machine plays a crucial role in the handling and transportation of silica grains, facilitating the movement of bulk materials within industrial facilities.

Efficiency: This machine enables efficient loading, unloading, and transfer of silica grains, reducing manual handling and streamlining material flow in production processes.

Dust Control: Silica grains can generate airborne dust particles, which pose health hazards. The suction machine helps control dust emissions, creating a safer working environment for operators.

Versatility: Silica grain suction machines can be customized with different suction capacities, hose lengths, and nozzle sizes to accommodate various processing requirements in different industries.

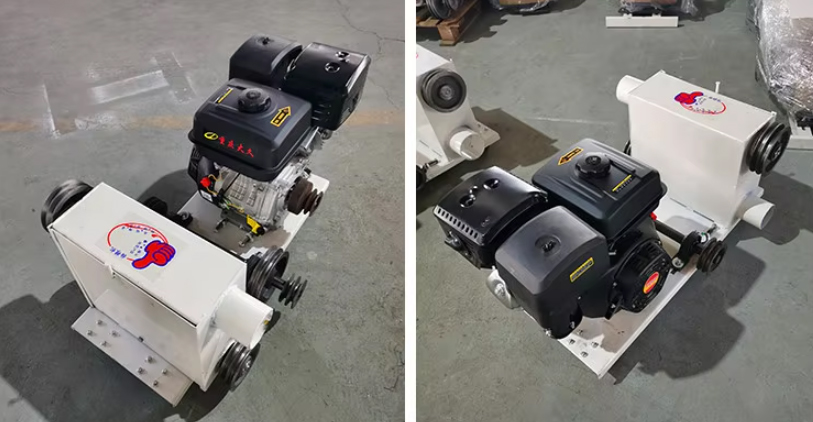

Suction System: The machine is equipped with a powerful suction system that generates negative pressure to lift and transport silica grains from one location to another.

Hose and Nozzle: A flexible hose with a suction nozzle is used to extract silica grains from storage containers, silos, or processing equipment, directing them to the desired destination.

Filtration System: Some silica grain suction machines feature filtration systems to capture dust particles and prevent them from being released into the environment during material transfer.

Control Panel: Operators can control the suction machine using a control panel, adjusting parameters such as suction power, flow rate, and direction to optimize material handling processes.

Improved Safety: By automating the handling of silica grains, the suction machine reduces manual labor and minimizes the risk of injuries associated with heavy lifting and material transport.

Efficient Material Transfer: The suction machine enables quick and efficient transfer of silica grains, enhancing production efficiency and reducing downtime in industrial operations.

Dust Suppression: The machine's dust control features help mitigate the risk of silica dust exposure, promoting a healthier work environment and compliance with safety regulations.

Customizable Options: Silica grain suction machines can be tailored to specific application requirements, allowing for flexible operation and seamless integration into existing production processes.

A silica grain suction machine is a specialized pneumatic conveying system designed to transport silica sand, quartz grains, or other abrasive granular materials efficiently and dust-free. It is widely used in industries such as foundry, glass manufacturing, construction, and electronics (e.g., silicon wafer production). The machine leverages vacuum or positive pressure to move silica grains through enclosed pipelines, minimizing material loss and workplace contamination.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.