Flexible grain auger

Flexible grain auger  Flexible auger

Flexible auger  Grain auger conveyor

Grain auger conveyor  Flexible auger conveyor

Flexible auger conveyor  Vehicle-mounted flexible grain auger

Vehicle-mounted flexible grain auger

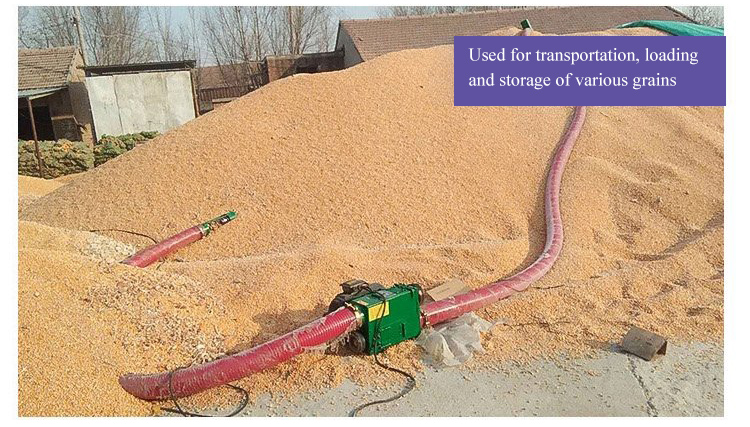

Used for conveying, suctioning, loading, stacking and storage of wheat, corn, rice, beans and other grains

![]()

![]()

![]()

Price:$80.00-$1000.00/Set

Consult now and enjoy a 10% discount

Pipe diameter: 100mm/120mm/160mm

Conveying length: 3m-12m

Vertical height: 3m-4m

Conveying capacity: 4-20 tons/hour

Voltage: 220/380v or design

Conveying angle: 0-90 degrees

Application: Suitable for transportation, loading and storage of wheat, corn, rice, cereals and other similar particles.

Commitment:

Flexible grain auger is a device that transports bulk grain through pipelines. Its main function is to transport grain from one device to another. The common one is to transport the bulk grain on the ground to the truck, and the bulk grain on the truck to the Grain depot, transporting granular materials to polishing machines and other equipment. Mainly suitable for wheat, corn, rice, beans and other similar grains. It has the characteristics of small size and easy portability.

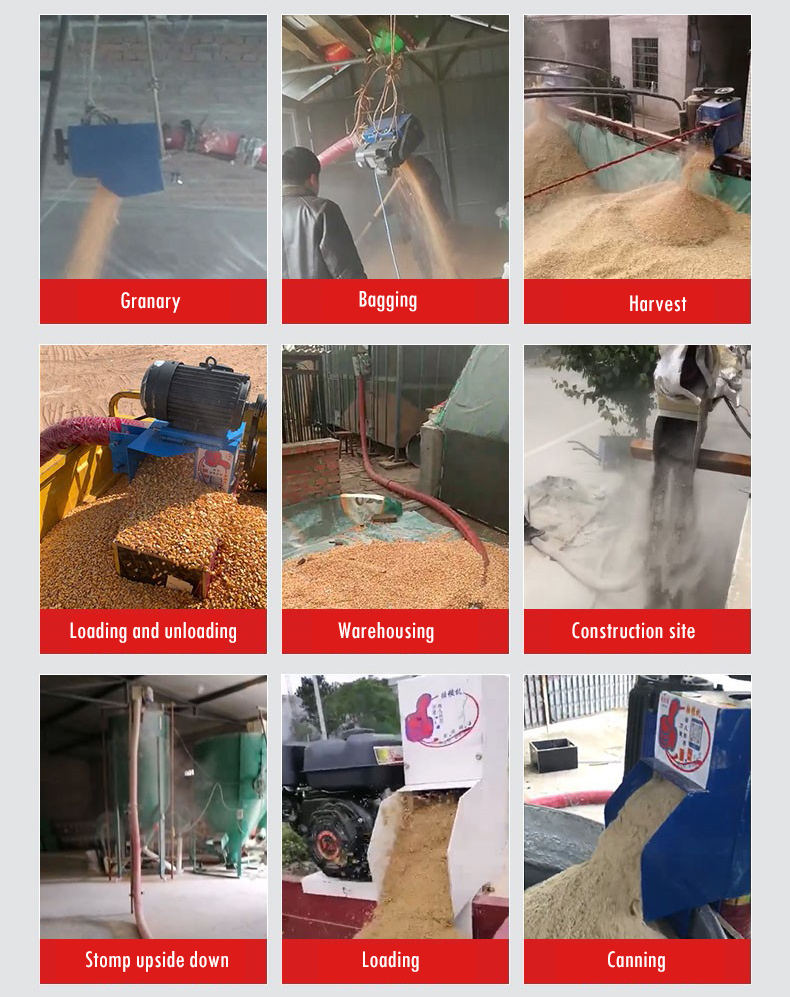

Flexible grain auger has a length of 3-30 meters, and can convey 20 tons of grain per hour. The weight of the machine is 75 kg. It can convey grains horizontally, obliquely or vertically. When the grain is conveyed vertically, the conveying capacity per hour can reach 6 tons. It is curved, movable, and can also be directly stuck on the raised wall of the truck box. It is easy to carry. It is a good equipment for loading, unloading, outgoing and warehousing of various grain crops, which saves labor and effort.

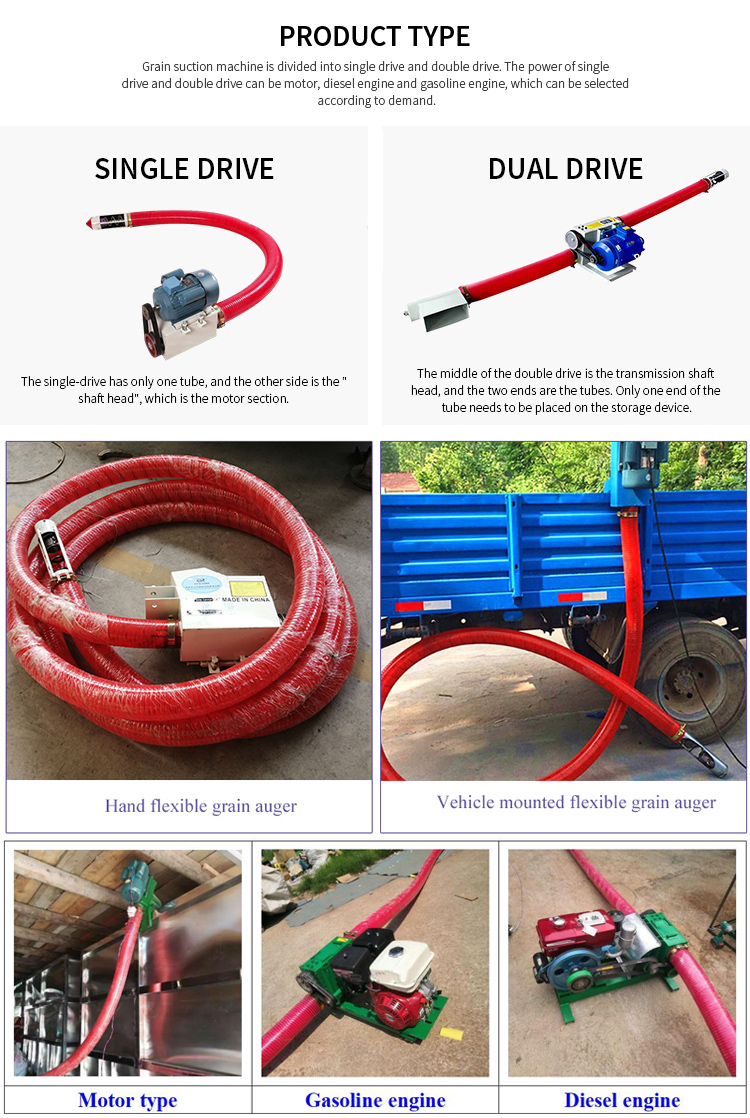

1. Hand flexible grain auger: It can be used for single suction, pressure delivery, or suction and pressure mixed conveying. Just after arranging the conveying pipes as needed, it can be conveyed horizontally, inclined, etc., such as conveying grain, wheat, rice, corn , sorghum, beans and granular materials such as plastics and resins.

2. Vehicle-mounted flexible grain auger: It can be installed on the carriage, automatically transports grain to the carriage, can be bent, moved, and is easy to carry. Loading and unloading trucks, clearing warehouse bottoms, etc., loading and unloading is fast and convenient.

The motor shaft and the coil spring are connected by screws. When starting the motor, the motor drives the coil spring to rotate. Under the action of the rotating spring, the grain in the collecting port will rise along the direction of the helix angle of the spring and reach the discharge port. Due to the action of gravity, the grain will be automatically unloaded.

Flexible grain auger can conveying materials horizontally, obliquely and vertically by using the pipeline layout, and can complete the conveying task independently by a single machine. Versatile function.

Conveying materials: wheat, soybean, corn, rice, sorghum, plastic, resin, rice and other particles.

Applicable occasions: suitable for loading, unloading, replenishing, unloading, overturning, stacking, and bulk loading in the production process of grain processing, feed processing and beer brewing industries in farms, docks, stations, large grain depots, etc. , Mechanized operation of bulk transportation and bulk unloading.

Flexible auger conveyor for rice

Flexible auger conveyor for corn

High conveying efficiency

According to the diameter of the hose, it can be divided into: φ50mm, 100mm, 120mm, 159mm, and the length of the whole machine can be divided into: 4 meters, 6 meters, 8 meters, 10 meters, 12 meters, 15 meters (3-15 meters can be produced), The processing output per hour can reach 2-20 tons.

Sealed delivery

The entire conveying process is completely airtight and is less affected by climatic and environmental conditions, which not only improves the working conditions, but also prevents the transported materials from absorbing moisture, contamination or mixing with other impurities, thus ensuring the quality of the transported materials.

Flexible power configuration

Single-phase, three-phase motor, gasoline engine, suitable for more occasions, safe and reliable, not easy to cause accidents.

Wide range of applications

It can not only suck and transport grain, but also suck and transport granular fertilizers, feeds, chemical products and other non-corrosive granular materials.

| Model No. | Length (Meters) |

Pipe diameter | Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

How can you select a machine, you need to know these:

1.What is your capacity do you need?

100mm with 5.7t/h, 120mm with 7-10t/h, 160mm with 10-20t/h

2.how many length do you need?

3.What is your need about power?

There are single motor/three phase/Gasoline engine/diesel engine

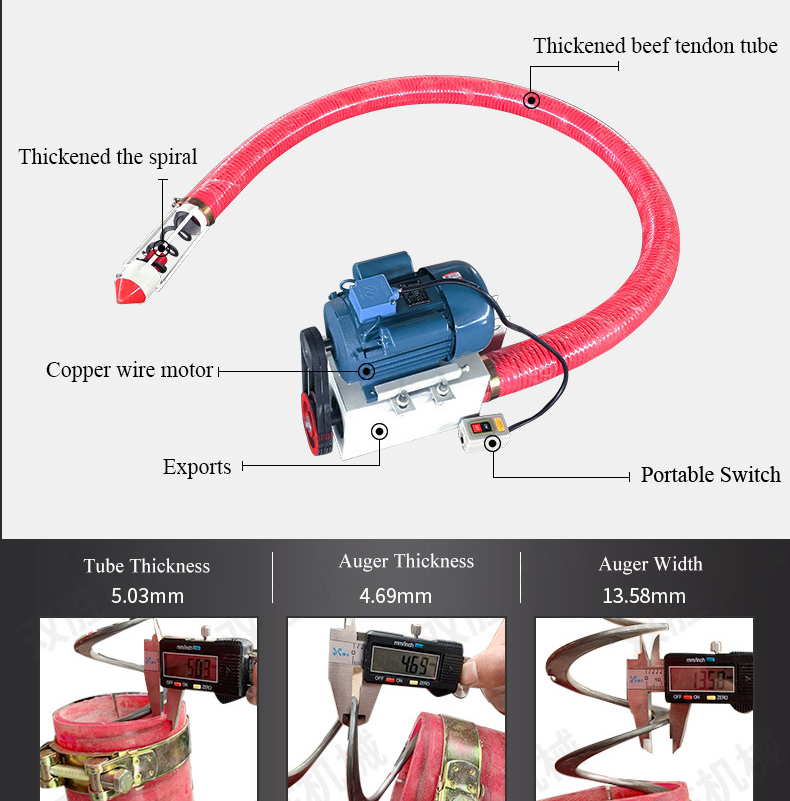

The flexible grain auger is composed of five parts: the flexible outer tube, the auger spring, the head and tail, and the motor.

Flexible outer tube: The spiral tube is made of high-quality beef tendon material, and the beef tendon tube has the characteristics of wear resistance and cold resistance.

Coil spring: Made of manganese steel, the helical blade adopts a shaftless structure, which is convenient for the rotation of the coil spring.

Head and tail: Humanized design makes the machine convenient and fast.

Motor: The motor adopts 220V single-phase electric/380V three-phase electric, power 3-4kw.

1. Different drives: divided into motor-driven, hand-drill-driven, diesel vehicle modification-driven and gasoline engine-driven.

2. Different placement positions: divided into double-tube flexible grain auger and single-tube flexible grain auger. The motor of the double-tube flexible grain auger can push back and forth on the ground. Both the feeding side and the feeding side are light and free. The single-tube motor is on the grain output side, which is a little bulky and suitable for use in fixed places that do not change positions frequently. For the unloading of grain points and warehouse loading, it is suitable to use double pipes.

The length of Dahan flexible grain auger is 5-10 meters, the grain suction is 2-6 tons per hour, and the weight of the machine is about 60 kg. Customized, regular models can be shipped on the same day, and customized models can be shipped within 7 days.

1. Grain breakage rate: The grain breakage rate affects the eating and processing quality of grains. Generally, the breakage rate of grains should be controlled at 0.1%.

2. Motor selection: The motor is the key component of the flexible grain auger, which directly affects the performance of the grain auger. It is recommended to use 380V voltage three-phase power above 8 meters, and the customized 220V high-horsepower motor can drive 12-15 meters.

3. Flexibility and output: Multi-purpose hoses are often equipped, which are flexible and convenient to use, but the length of the conveying distance will directly affect the output.

4. Energy consumption: flexible grain auger mostly uses motor or diesel engine. Different output requires different motor power. Users who cannot reach the power can choose diesel engine.

5. Application fields: Pneumatic conveying flexible grain auger is mainly used in grain depots, wharfs, loading and unloading ships, and has the effect of cleaning and dusting materials. With the development of technology, it can also be used in chemical, construction, and other particle and powder conveying fields.

6. Equipment life: The average service life of the main accessories is about 5 years, and the accessories can be replaced after 5 years.

Q: How many phases does Flexible grain auger use?

A: The machine has two-phase and three-phase, which can be selected according to needs. 380V voltage is applicable to the needs of 100mm*12m/120*8m or more.

Q: How many meters can be made?

A: It can do 30 meters, the motor is in the middle, the inlet pipe is 15 meters, and the outlet pipe is 15 meters, and the 380V voltage must be applied.

Q: How many meters can it be lifted vertically?

A: 220V can increase 3 meters, 380V can increase 3-5 meters (data subject to general grain)

Q: What are the materials of the spiral and the tube, will they wear out the tube? Will the spiral break?

A: The spiral is made of a manganese steel, imported from South Africa, with good hardness, elasticity and wear resistance, and the outer edge is specially treated to be smooth, which will not cause damage to the tube. The tube is a custom-made beef tendon tube, which remains elastic throughout the year and can be bent arbitrarily. And add wear-resistant material to prolong the life of the tube.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.