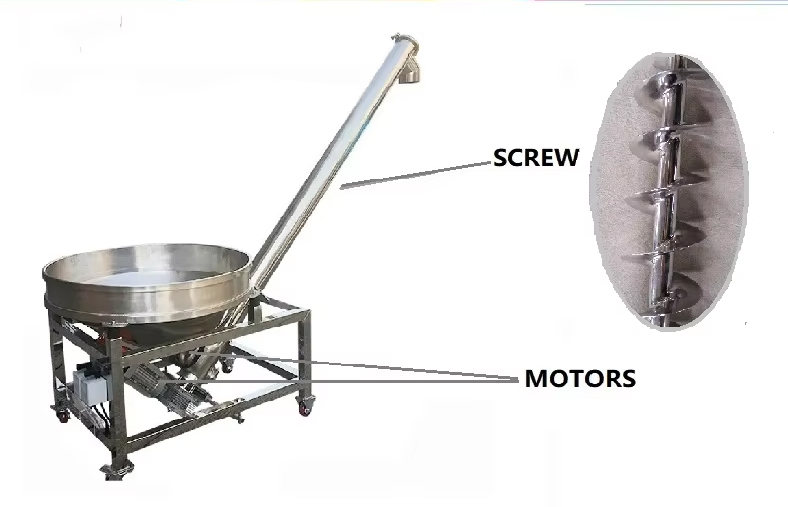

Yellow corn flour incline auger conveyor is a machine that uses a motor to drive the spiral to rotate and push the material to achieve the purpose of conveying. This conveyor has the characteristics of simple structure, small cross-sectional area, and convenient closed conveying. It is suitable for conveying various types of powdered, granular and block materials. It can be moved at will and can be continuously conveyed at any horizontal, inclined or vertical position. It is particularly suitable for field mobile operations. Its design takes into account the horizontal, inclined and vertical conveying of granular or powdered materials. The conveying distance generally ranges from 2 meters to 70 meters.

Yellow corn flour incline auger conveyor is a device specially designed to efficiently and accurately convey yellow corn flour along an inclined path. This type of conveyor is commonly used in food processing plants, especially for the production of products such as tortillas, cornbread and various baked goods.

Material transportation: Incline spiral conveyors are responsible for moving yellow corn flour from one point to another, usually from a lower position to a higher position within the production line.

Inclined conveying: The conveyor is specially designed to operate on an incline, allowing the corn flour to move vertically, which is essential in many production processes.

Continuous flow: It ensures a continuous flow of corn flour, preventing bottlenecks in the production line and maintaining efficiency.

Screw: The screw spiral inside the conveyor rotates to propel the yellow corn flour along the inclined path.

Hopper: The hopper at the lower end of the conveyor is used to hold the yellow corn flour, which is then fed into the screw conveying system.

Drive unit: This component provides the power required to rotate the screw conveyor screw and move the material along the conveyor.

Inclined frame: The frame of the conveyor is designed to support the inclined angle, ensuring stable and efficient transportation of corn flour.

Space efficiency: Inclined screw conveyors save space because they can transport materials vertically, thus saving valuable floor space in the production area.

The main components of the Yellow corn flour incline auger conveyor include the screw shaft and the hanging bearing, the head and tail shaft connections are embedded tongue type, installation and disassembly do not require axial movement, and maintenance is convenient. The variable diameter structure is adopted to increase the volume of the hanging bearing, avoid the contact between the hanging bearing and the material, and the service life of the hanging bearing can reach more than two years. All transmission parts adopt floating connection, and the hanging bearing is a universal joint structure, so that the spiral body, hanging bearing and tail assembly form an integral rotating floating body, which can rotate freely to avoid the conveying resistance within a certain range, without material jamming or blocking. The head and tail bearing seats are both outside the shell, and all bearings use multi-layer sealing and matching sealing technology, which has a long bearing life.

Yellow corn flour incline auger conveyor is a valuable asset in food processing facilities, which helps to convey yellow corn flour efficiently and smoothly along the inclined path. By selecting the right equipment and maintaining it properly, manufacturers can ensure a smooth production process and produce high-quality products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.