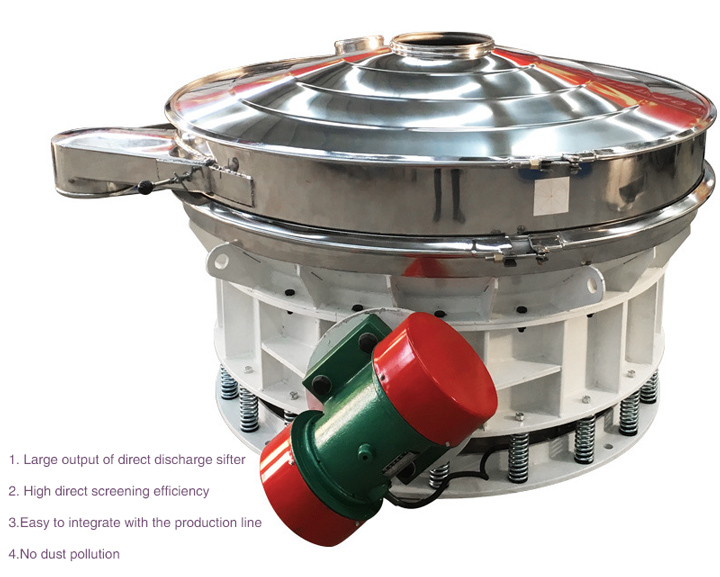

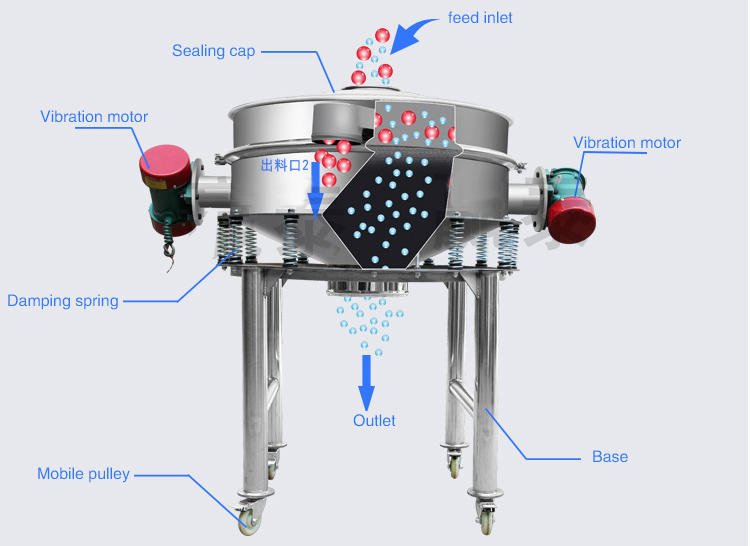

Direct discharge sifter is mainly used in the screening of powder particles. In the flour, additives and other industries, the following are the advantages of this machine in powder screening.

1. Large output of direct discharge sifter

The direct discharge sifter has a complete range of models with diameters of 600mm, 800mm, 1000mm, 1200mm, 1500mm, 2000mm, etc. It can be used in single layer or multiple layers, and can process materials of different specifications at the same time, with greater processing capacity. Continuous 24 hours of non-stop screening work, greatly increasing the screening output.

2. High direct screening efficiency

The direct discharge sifter is simple to operate, has automatic discharge function, can feed evenly, reduces labor costs, and can also work automatically, which greatly improves the screening efficiency; and the screen has high utilization rate, is not easy to block, and is easy to replace, which is for production. Save time and improve screening efficiency. Such as: ZPS-1000 sieve machine with 24 mesh screen, which can reach 350kg/150 seconds.

3.Easy to integrate with the production line

The direct discharge sifter is small in size, does not occupy space, and is convenient to move. It is suitable for arrangement on the production line and saves costs; the fully enclosed structure makes it difficult for slurry and dust to escape, which reduces the labor cost of later cleaning; the direct discharge sifter equipment has noise reduction treatment And low energy consumption, suitable for layout on the production line.

4.No dust pollution

All joints inside the direct discharge sifter are processed by high-precision polishing, which has strong sealing and will not be cross-contaminated. The screened materials meet the standards of medicine and food. It is applicable to a wide range of industries, including powder, granular, slurry, etc. Sieving is more common in the daily sieving, filtering and impurity removal of wheat flour, flour, and additives.

5.Environmental protection and hygiene

The direct discharge sifter is made of high-quality stainless steel material, ultra-low noise design, quiet and environmentally friendly, all internal joints are high-precision polishing treatment, strong sealing, will not be cross-contaminated, and the screening materials meet the health standards of the medicine, food and other industries.

If you are looking for screening and screening solutions for any of your powder products, please contact us immediately!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.