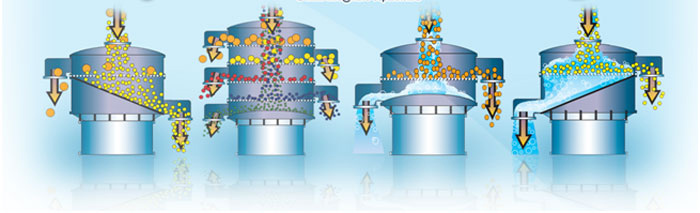

Vibro sifter uses the vibration force generated by the vibrator to vibrate the screen box and screen mesh, causing the materials to continuously fluctuate and jump in the screen box. Due to the different particle sizes and shapes of materials, they will produce different motion trajectories under the action of vibration force. Smaller particles will fall into the silo below through the mesh of the screen, while larger particles cannot pass through the screen and are blocked above the screen. In this way, the material is separated into particles of different sizes.

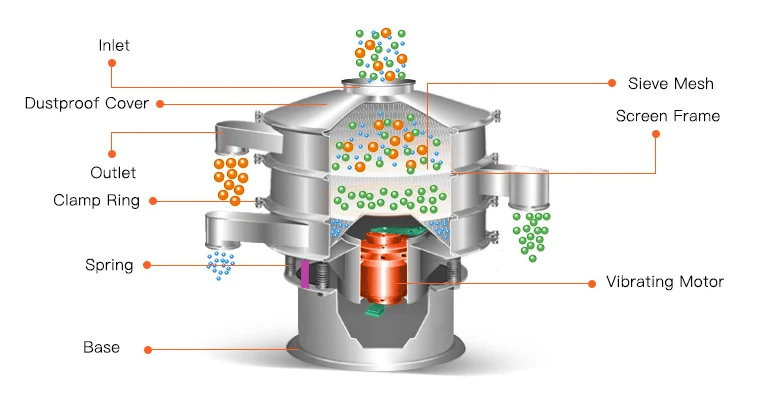

Vibro sifter is mainly composed of screen box, vibrator, screen, damping spring and bracket. The screen box is the part that carries materials. It is usually made of welded steel plates and has certain rigidity and strength. The vibrator is the power source of the vibrating screen. It is usually driven by a motor and transmits the vibration force to the screen box through an exciter. The screen is a key component of the vibrating screen. It is made of metal wire or polymer material with meshes of different apertures and is used to screen materials. The damping springs and brackets play the role of support and damping, which can effectively reduce the impact of the vibration of the vibrating screen on the surrounding environment.

1. The work of vibration motor: The vibration motor of the vibrating screen is a special motor that can generate vibration. The working principle of a vibration motor is that when electric current passes through the coil of the motor, an electromagnetic field is generated. The electromagnetic field interacts with the motor's rotor, causing the rotor to rotate. The rotation of the rotor drives the eccentric block to rotate together. The rotation of the eccentric block will generate vibration and transmit it to the screen.

2. Vibration of the screen: The vibration generated by the vibration motor will be transmitted to the screen, causing the screen to vibrate. The vibration of the screen will cause the materials in the screen holes to move up and down. When the particle size of the material is smaller than the sieve hole, the material will fall under the sieve through the sieve hole; when the particle size of the material is larger than the sieve hole, the material will stay on the sieve.

3. Classification or dehydration of materials: Due to the vibration of the screen, the materials will move up and down. When the particle size of the material is smaller than the sieve hole, the material will fall under the sieve through the sieve hole; when the particle size of the material is larger than the sieve hole, the material will stay on the sieve. In this way, material classification can be achieved.

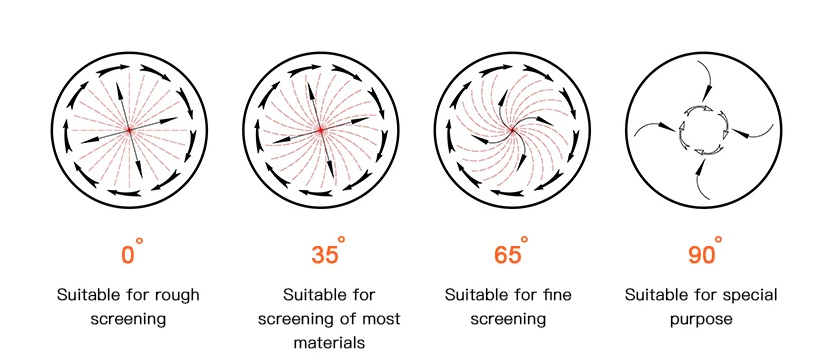

The vibration frequency and amplitude of the Vibro sifter are two important parameters that will affect the classification effect of the vibrating screen. The higher the vibration frequency, the smaller the particle size of the material; the greater the amplitude, the higher the classification accuracy of the material.

Vibro sifter is widely used in coal, mining, metallurgy, chemical, food, pharmaceutical and other industries to classify or dehydrate various materials. There are many types of vibrating screens, including circular vibrating screens, linear vibrating screens, square vibrating screens, vertical vibrating screens, etc. Different vibrating screens have different characteristics and uses.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.