Vibrating sifter is a commonly used solid screening equipment, widely used in mining, metallurgy, chemical industry, building materials, food, medicine and other industries. It uses vibration force to separate and classify materials according to different particle sizes, and has the characteristics of high efficiency, accuracy and reliability.

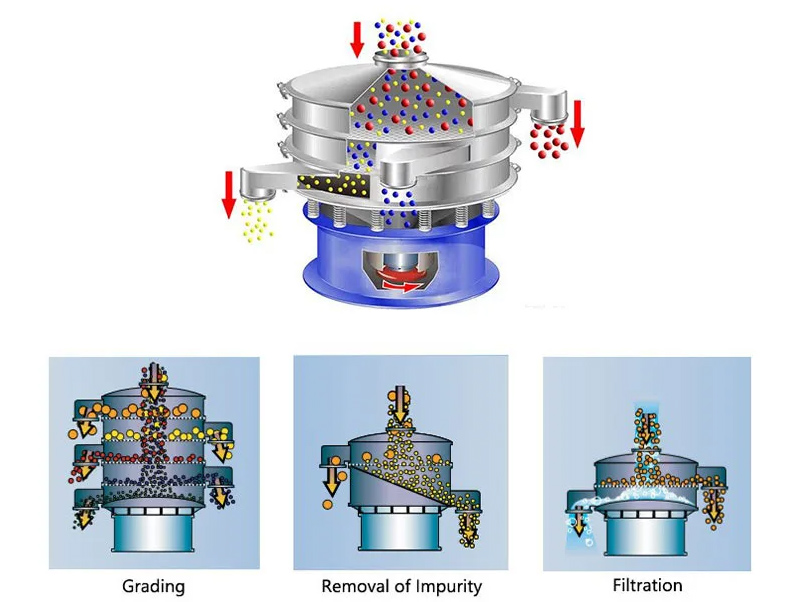

The working principle of vibrating sifter is based on the action of vibrating force. It usually consists of a screen box, a vibrator, a screen, a vibration reduction device and a feed port. The material enters the screen box through the feed port, and the vibrator in the screen box generates vibration force, causing the material to vibrate on the screen. Due to the different particle sizes and shapes of the materials, larger particles will be screened out through the aperture of the screen, while smaller particles will pass through the screen to achieve the purpose of separation and classification.

Screen box: The screen box of the vibrating sifter is usually made of welded steel plates. It has high strength and rigidity and can withstand large vibration forces and material impact.

Vibrator: The vibrator of the vibrating sifter usually uses a biaxial or three-axis vibrator. The vibration force is generated by the excitation motor, which causes the screen box to vibrate horizontally or tiltedly, prompting the material to move on the screen surface.

Screen mesh: The screen mesh of vibrating sifter is usually made of wire mesh or polymer screen plate, with different apertures and mesh shapes to adapt to the screening requirements of different materials.

Vibration damping device: Vibrating screens are usually equipped with vibration damping devices to reduce the transmission of vibration to the support structure and reduce the impact of noise and vibration on the environment and operators.

Feed port: The feed port of the vibrating screen is usually reasonably designed to ensure that materials can enter the screen box evenly and achieve effective screening results.

Mining and metallurgical industry: used for screening, grading and beneficiation of ores, such as coal, metal ores, etc.

Chemical industry: used for screening and classifying chemical raw materials, such as granular chemical raw materials, resin, rubber, etc.

Building materials industry: used for screening and grading building materials, such as sand, cement, concrete, etc.

Food industry: used for screening and classifying food raw materials, such as powdered food additives, cereals, powdered sugar, etc.

Pharmaceutical industry: used for screening and grading pharmaceutical raw materials, such as pharmaceutical powders, pills, etc.

Efficient screening: Through the action of vibration force, the vibrating screen can quickly and effectively screen materials and improve screening efficiency.

Precise classification: The screen aperture of the vibrating screen can be selected as needed to achieve precise classification effects and meet different particle size requirements.

Reliable and stable: The vibrating screen has a solid structure, uniform vibration force, stable and reliable operation, and can work continuously for a long time to reduce downtime.

Energy saving and environmental protection: The vibrating screen uses vibration force for screening. Compared with other screening equipment, it can save energy and reduce environmental pollution.

Easy operation: The operation of the vibrating screen is relatively simple. You only need to set the appropriate vibration parameters and screen aperture to achieve the ideal screening effect.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.