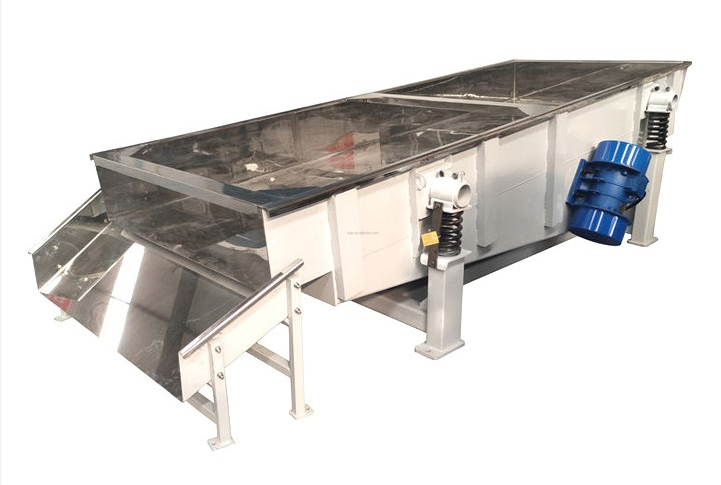

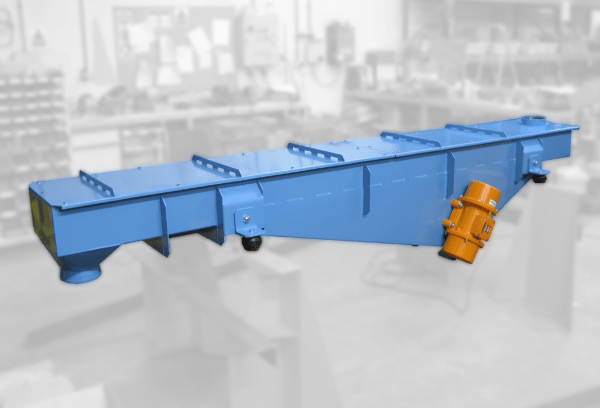

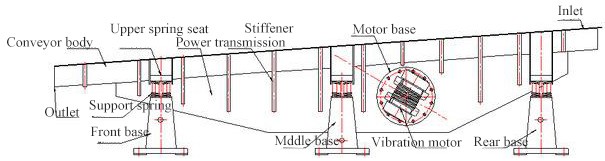

Vibrating conveyors are commonly used industrial equipment used to convey bulk materials in a vibrating manner. Vibrating conveyors usually consist of vibration motors, conveying troughs, support frames, etc. The vibration motor generates vibration force and transmits it to the conveyor trough, causing the material to continuously jump to achieve the purpose of transportation. This transportation method has the advantages of high efficiency, energy saving, and simple structure.

However, vibrating conveyors also have some shortcomings, such as noise and vibration, material blockage and accumulation, material damage, etc. It is necessary to comprehensively consider its advantages and disadvantages according to the specific situation to select appropriate conveying equipment. This article will examine the disadvantages of vibrating conveyors in detail.

Noise and vibration

Vibrating conveyor will produce large noise and vibration during operation. Due to the nature of vibration, these noises and vibrations are transmitted to the structures and equipment surrounding the conveyor, potentially causing disruption and damage to the work environment and other equipment. In addition, workers exposed to high-intensity vibration environments for long periods of time may also suffer physical discomfort and health problems.

Material blockage and accumulation

Vibrating conveyor may have problems with material clogging and accumulation during transportation. Due to the force of vibration, some bulk materials may adhere to the walls of the conveyor during transportation, causing blockage. In addition, some fine powder materials may accumulate during the transportation process, causing blockage of the transportation channel and affecting the normal material flow.

Material damage and dispersion

The vibrating force of a vibrating conveyor can cause damage to some sensitive or fragile materials. During the vibration process, some fragile materials may be broken, pulverized or deformed, resulting in reduced product quality. In addition, the vibration force may also cause some fine materials to dust, causing the materials to disperse in the surrounding environment, causing environmental pollution and safety hazards.

Energy consumption and maintenance costs

Vibrating conveyors usually require larger power to provide sufficient vibration force. This means that a large amount of electricity is consumed during operation, increasing energy costs. In addition, due to the working principle and complex structure of the vibrating conveyor, maintenance and repair also require a certain amount of cost and time. Maintenance of equipment requires periodic maintenance and cleaning to ensure its normal operation and extend its service life.

Limit conveying capacity

The conveying capacity of vibrating conveyors is subject to certain limitations. Due to the limitations of equipment structure and vibration force, the conveying speed and processing capacity of vibrating conveyors are relatively low. For some large flow, high speed or long distance conveying requirements, vibrating conveyors may not be able to meet the requirements, and other more suitable conveying equipment needs to be considered.

Although the vibrating conveyor has some shortcomings, it is still a widely used conveying equipment, especially suitable for some specific materials and scenarios. When selecting and using a vibrating conveyor, it is necessary to comprehensively consider its advantages and disadvantages, and make reasonable selection and configuration according to actual needs. In addition, regular maintenance and upkeep are also important measures to ensure the normal operation of the vibrating conveyor and reduce the impact of shortcomings.

Dahan Manufacturer produces various types of vibrating conveyors and they are widely used. If you are interested in vibrating conveyors, please click on the online chat for consultation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.