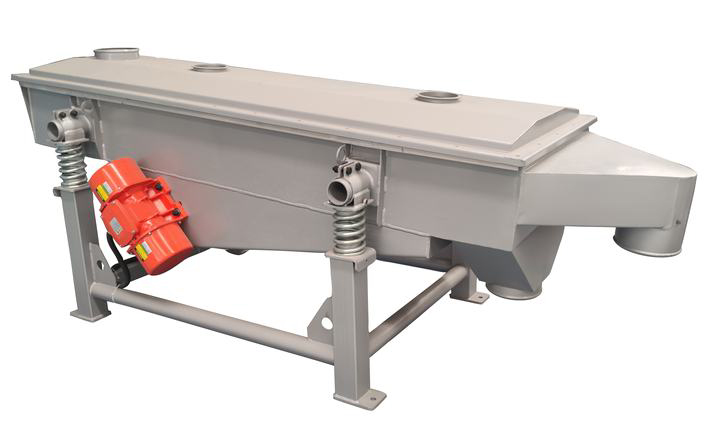

Rectangular vibrating screen is specially designed for large output, suitable for safe screening, grading and dust removal of powder and granules. This article will explain the rectangular vibrating screen in detail for you.

Rectangular vibrating screen is very suitable for removing impurities from powder or granules, separating different specifications of the same product, the mesh size ranges from 3/8 inch (10 mm) to 400 mesh (38 microns), widely used in abrasive industry, chemical industry, Food industry, pharmaceutical industry, fertilizer industry, plastic granules and other industries.

Common applications: feed mills, plastic pellet recycling, food processing plants, sand and gravel production lines, etc.

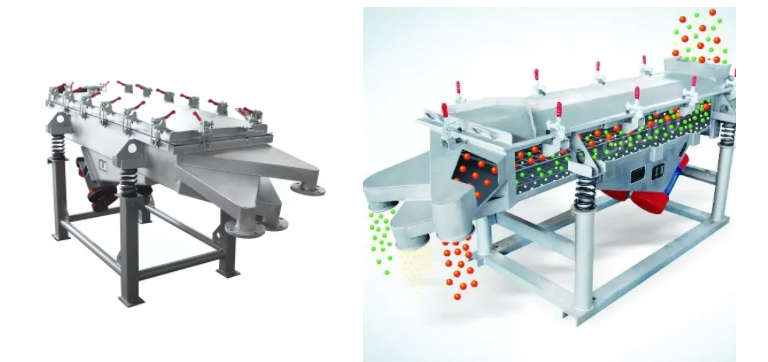

The linear screen relies on two reverse motors with the same frequency to make the material jump straight forward on the screen surface, and the material smaller than the sieve hole diameter falls into the lower layer through the screen, and separates the originally disordered particles, that is, stratifies according to the particle size to form the bottom. Arrangement of small particles and coarse particles at the top, so as to achieve the purpose of screening and grading materials

1. The mesh size ranges from 3/8 inch (10 mm) to 400 mesh (38 microns), and the screening efficiency can reach more than 96%.

2. Available in 500mm to 1,500mm wide and 1,500 to 4,000mm long screening areas, allowing up to 20 tons/hour of processing capacity.

3. It can be installed and used in single-layer or multi-layer combination, and 2-7 kinds of products of different specifications can be separated at one time.

4. Fully enclosed structure, all incoming materials are automatically unloaded, and there is no material stored in the machine, which is more suitable for assembly line operations.

5. The inclination angle of the screen surface can be adjusted to balance the screening accuracy and output, and the inclination angle of the screen surface does not exceed 25°.

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

The above parameters are for reference only, and different designs can be adopted according to the actual use:

The above is an introduction to the rectangular vibrating screen, I hope it will help you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.