Vibrating screen frame is an important part of the vibrating screen system, which provides structural support to ensure the stability and tension of the screen. The main function of the vibrating screen frame is to support the screen so that it can withstand the stress generated during vibration and screening, and maintain appropriate tension to ensure the effectiveness and accuracy of screening.

The vibrating screen frame plays a vital role in the entire screening process. Its main functions are as follows:

1. Support the screen

Fix the screen: The mesh frame firmly fixes the screen in the screen box to prevent the screen from displacement or damage during vibration.

Provide tension: The mesh frame keeps the screen flat through a certain tension to ensure screening accuracy.

2. Transmit vibration

Transfer vibration energy to the screen: The mesh frame evenly transfers the vibration energy generated by the vibration motor to the screen, causing the screen to resonate, thereby achieving the purpose of screening.

3. Separate materials

Achieve screening: Screens with different apertures classify materials according to particle size.

4. Protect the screen

Extend the service life of the screen: The mesh frame evenly distributes the load to prevent the screen from being damaged due to excessive local force.

In summary, the vibrating screen frame is one of the core components of the vibrating screen, and the quality of its design directly affects the screening effect and the service life of the equipment.

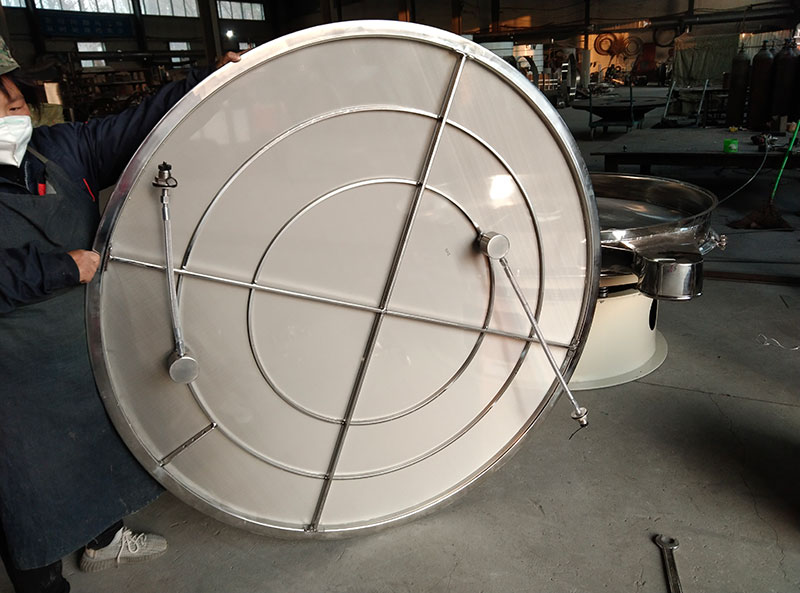

1、Circula vibrating screen frame

At present, there are three types of frame structures commonly used in the market: mother-and-child frame, U-shaped frame, and adhesive frame. Different frame structures use different vibrating screens.

The vibrating screen frame is divided into U-shaped frame, mother-child button frame, mother-child separated frame, glued frame and so on.

Vibrating screen frame u-shaped grid

Also known as sub-mother screen structure, it is a very commonly used type of rotary vibrating screen. First, use a press tool to fix the screen with a thick wire diameter in the U-shaped groove. This layer of screen is called mesh, and then the working screen Lay it flat on top of the mesh, and fix it around with clamps.

Advantages: It is faster to replace the working net, the mesh under the working net acts as a skeleton, supports the working screen, ensures the flatness of the stainless steel vibrating screen surface, prevents the impact of materials from collapsing the working net, and at the same time prevents bouncing balls on the screen plate Hit the work net and break the work net.

Vibrating screen frame mother-and-child frame

The female buckle net frame is also called the male and female slot flange net frame, which is two flanges, one groove, and one convex groove. The convex groove flange is welded into the screen frame, and the groove flange is used as the movable part to connect the The screen is placed between the two flanges, locked with screws, and the screen surface is naturally stretched and flat. Generally, the screens of 12-30 mesh rotary vibrating screens adopt this structure.

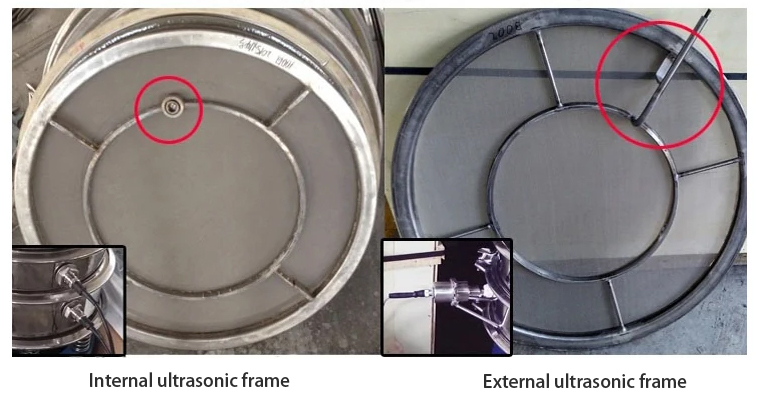

Vibrating screen frame adhesive grid

This grid structure is commonly used in ultrasonic vibrating screens.

Advantages: Fast net loading speed, since the screen is directly glued to the grid frame, a set can be pre-installed as a spare, and it can be replaced directly together with the screen when replacing.

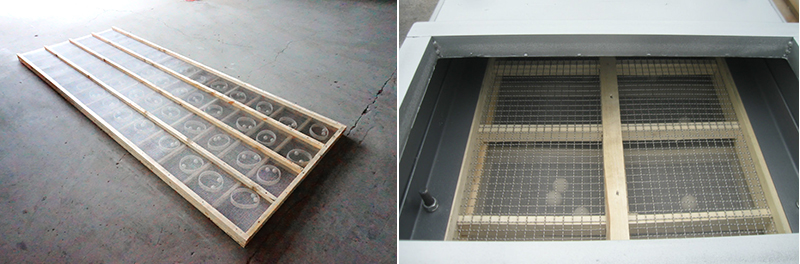

2. Square vibrating screen frame

Square vibrating screen frame can be divided into two different frame structures: steel frame, wooden frame and metal frame.

Steel frame

Selection criteria: When the material to be screened must be made of steel, such as food, medicine, etc.; the second screening requirement, under normal circumstances, when the mesh size of the screen is large, the most suitable coarse mesh above 30 mesh is suitable.

Advantages: clean, strong and durable; Disadvantages: The installation of the screen requires strong professionalism, and the service life of the screen is relatively low.

Wooden frame

Selection criteria: When there is no special requirement in the industry, the first choice for the screen mesh is below 60 mesh is the wooden frame.

Advantages: convenient screen replacement, relatively long service life of the screen, low manufacturing cost, and convenient on-site manufacturing; Disadvantages: easy to damage, not suitable for materials that are afraid of pollution and wet screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.