A V-type mixer is a crucial piece of equipment in industries that deal with the blending of powders and solids. This specialized mixer is designed to ensure thorough mixing of dry materials to create a homogeneous blend. It features a V-shaped container with two asymmetric cylinders that rotate to mix the materials thoroughly. This design promotes efficient blending and prevents material accumulation in the corners, ensuring a homogeneous mixture.

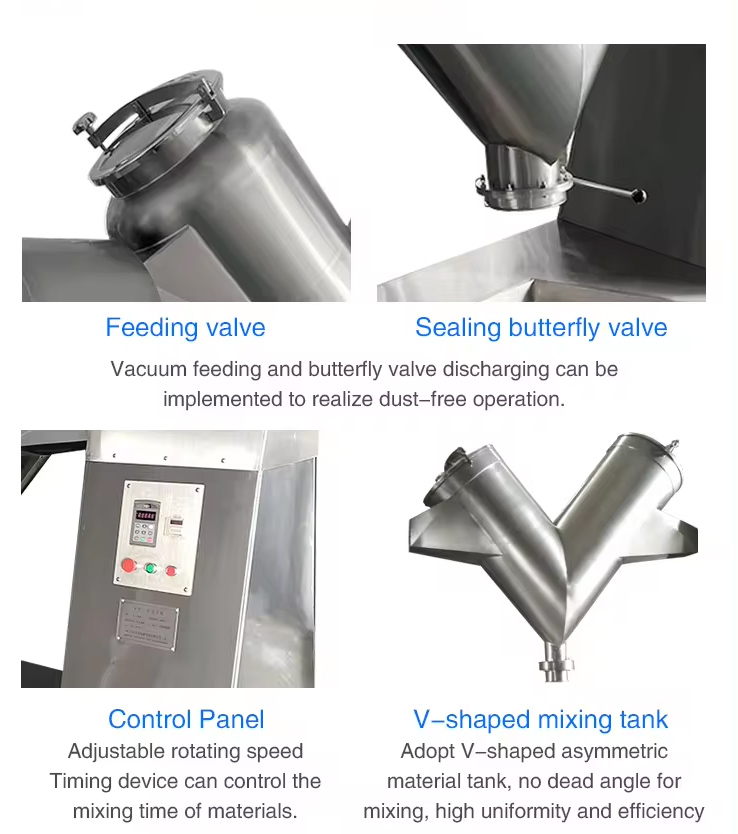

V-Shaped Container: The mixer has a V-shaped container that promotes efficient blending by facilitating the movement of materials towards the center. This design prevents material accumulation in the corners, ensuring a uniform mixture.

Asymmetric Cylinders: Inside the V-shaped container, there are two asymmetric cylinders that rotate in opposite directions. This movement effectively mixes the powders and solids, creating a consistent blend.

Material Construction: V-type mixers are typically constructed from stainless steel or other materials that are resistant to corrosion and easy to clean, ensuring product purity and hygiene.

Variable Speed and Time Settings: Many V-type mixers come with adjustable speed and time settings, allowing operators to customize the mixing process based on the specific characteristics of the materials being blended.

Safety Features: These mixers are equipped with safety features such as interlocking mechanisms to prevent accidents and ensure operator safety during operation.

Easy Discharge: V-type mixers are designed for easy discharge of the blended materials, facilitating efficient transfer to downstream processes or storage containers.

Versatility: These mixers can handle a wide range of materials, including powders, granules, and solids, making them suitable for various industries such as pharmaceuticals, food processing, chemicals, and cosmetics.

Uniform Mixing: The V-shaped design and rotating cylinders ensure thorough mixing, resulting in a consistent blend of powders and solids.

Efficient Operation: V-type mixers are known for their efficiency in blending materials quickly and effectively, reducing processing time and improving productivity.

Gentle Mixing: These mixers can provide gentle blending for delicate materials, preventing damage or degradation during the mixing process.

Easy to Clean: The design of V-type mixers allows for easy cleaning and maintenance, minimizing downtime between batches and ensuring product quality.

Space-Saving: The compact design of V-type mixers makes them suitable for facilities with limited space, optimizing floor space utilization.

Pharmaceutical Industry: Used for blending powders in the production of medications, supplements, and pharmaceutical formulations.

Food Processing: Ideal for mixing ingredients in the production of food products such as spices, seasonings, and nutritional supplements.

Chemical Industry: Utilized for blending various chemicals, pigments, and additives in the manufacturing process.

Cosmetics Industry: Employed for mixing powders and pigments in the production of cosmetics and personal care products.

Research and Development: Used in laboratories and research facilities for experimentation and product development involving powder blending.

Loading: The powders or solids to be mixed are loaded into the V-shaped container of the mixer.

Rotation: The asymmetric cylinders inside the container rotate in opposite directions, creating a tumbling motion that thoroughly blends the materials.

Mixing: The materials move towards the center of the V-shaped container and are continuously mixed until a homogeneous blend is achieved.

Discharge: Once the mixing process is complete, the blended materials can be discharged through a chute or opening at the bottom of the mixer for further processing or storage.

In conclusion, a V-type mixer for powders and solids is a versatile and efficient blending solution for industries that require homogeneous mixing of dry materials. With its unique design, ease of operation, and ability to handle a variety of materials, the V-type mixer plays a vital role in ensuring product quality and consistency in manufacturing processes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.