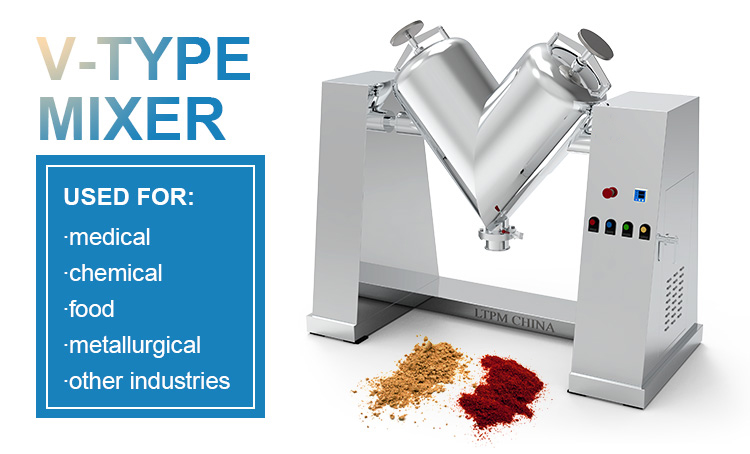

It is mainly used for mixing granular, powdery and a small amount of viscous materials to achieve uniform mixing and uniform dispersion.

![]()

![]()

![]()

Price:$700.00-$3,500.00/Set

Consult now and enjoy a 10% discount

Barrel Volume:20L

Max. Loading Volume:8 L

Max. Loading Capacity: 10kg

Voltage:120V/220V/380V/440V/CUSTOMIZABLE

Power:0.75 kW

Material:SUS304, SUS316L

Weight:150 KG

Application: Widely used in pharmaceutical, chemical, food, metallurgy, pesticide, plastic and other industries, for mixing various granular, powdery and a small amount of viscous materials, such as medicine powder, additives, food additives, cosmetic raw materials, etc.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

V-type mixers are V type dry powder mixer, also called V blender , which are made by rotating a V-shaped container, made of 2 cylinders welded at 75° to 90°, which can be rotated to mix the ingredients by diffusing mixing to achieve fast and uniform mix.

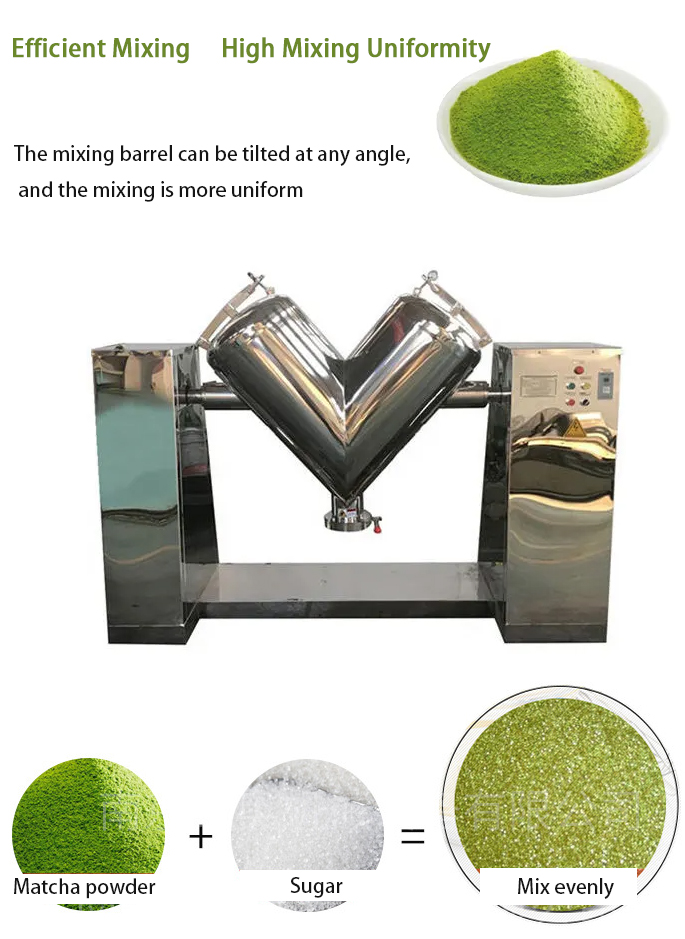

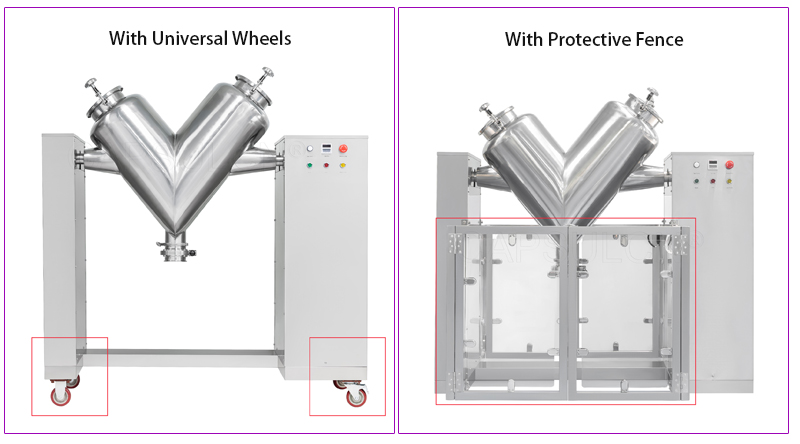

The V-type mixer is made of stainless steel, the inner wall is polished, the mixing is uniform, the material flows smoothly during the mixing period, and it is not easy to damage the raw materials. It can be designed as single or double arms according to customer requirements.

V-type mixer is a multi-functional mixing equipment widely used in industries that require uniform mixing of dry powder, granules and other solid materials. Its design promotes efficient mixing and ensures consistent product quality. Some common uses for V-blenders include:

Pharmaceutical industry: For mixing powders, granules and other pharmaceutical ingredients. They are commonly used in the manufacture of tablets, capsules and other solid dosage forms.

Chemical Industry: For mixing and homogenizing different types of chemicals, pigments, dyes and additives. They are used to ensure an even distribution of ingredients and to achieve the desired chemical reactions.

Food and beverage industry: For mixing dry ingredients such as spices, flavorings, powders and additives. They are commonly used in the production of bakery products, snacks, beverages and other food products.

Cosmetics and personal care industry: For mixing various ingredients such as pigments, powders, fragrances and additives. They help achieve uniformity and consistency in cosmetic formulations.

Nutraceutical industry: For blending vitamins, minerals, herbal extracts and other nutritional ingredients. They ensure an even distribution of active ingredients to create homogeneous nutraceutical products.

Veterinary and animal feed industry: For mixing different types of feed ingredients such as grains, proteins, vitamins and minerals to achieve a balanced and homogeneous feed mixture.

Research and Development: V-blenders are also used in R&D laboratories for small-scale mixing and formulation experiments. They provide a convenient and efficient way to mix and test various ingredients and formulations.

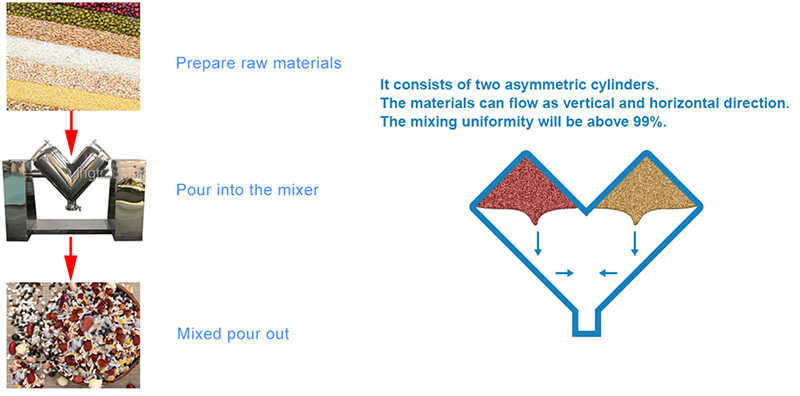

The working principle of a V-type mixer involves mixing and homogenizing materials through a combination of convective and diffusion mixing mechanisms. Here's a general overview of how it works:

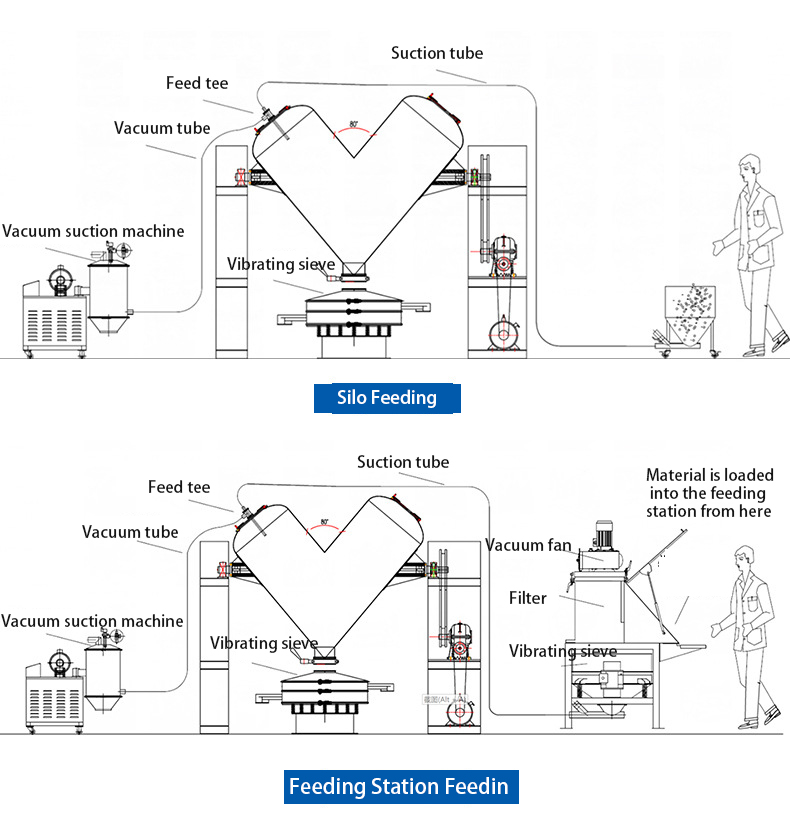

Feeding: Load the materials to be mixed into the V-type mixer of the mixer. The chamber is usually equipped with a cover or cover to prevent spillage of the material during mixing.

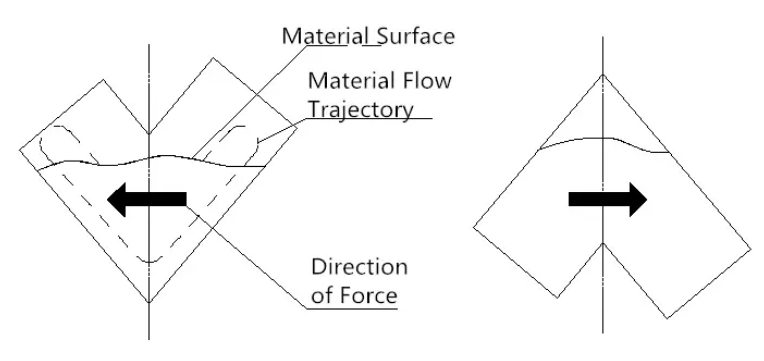

Mixing Action: Mixers operate by a combination of tumbling and cascading actions. The V-type mixer keeps the material rolling and flowing along the chamber wall.

Convective Mixing: As materials tumble and flow, they undergo convective mixing. This occurs when particles move from the bottom to the top of the V-shaped mixer and vice versa. The movement of the particles facilitates the mixing and blending of materials.

Diffusion Mixing: In addition to convective mixing, diffusive mixing also occurs in V-blenders. This occurs when particles move toward each other due to differences in size, shape and density. It allows particle redistribution and enhances the mixing process.

Mixing Efficiency: The V-Mixer design promotes efficient mixing by providing a large surface area for material contact and movement. The V-shaped mixer ensures that the material undergoes multiple collisions and interactions, resulting in improved mixing efficiency and uniformity.

Unloading: After the required mixing time is reached, the mixed material can be unloaded from the mixer. Discharge can usually be done through a bottom outlet or a side discharge, depending on the specific design of the V-blender.

Efficient mixing

Designed to provide efficient, thorough mixing. The V-type mix and the tumbling and cascading action of the materials inside promote efficient mixing and ensure even distribution of all ingredients.

Handle materials gently

Controlled vibrations ensure smooth transport of materials without damage or degradation. This is especially beneficial for handling materials that are prone to breakage, segregation or degradation during transport.

Time and cost efficiency

Efficient mixing action reduces mixing time, increasing productivity and saving costs. The ability to achieve uniform mixing in less time increases productivity.

Gentle mixing

Provides gentle mixing action, minimizing excess heat or mechanical stress on the material. This is especially useful when working with temperature sensitive or fragile materials.

Easy to clean and maintain

Typically have removable parts and a smooth, easy-to-clean surface for quick and thorough cleaning between batches.

Customizable features

Can be customized to meet specific process requirements. They can be equipped with adjustable mixing speed, mixing time and other parameters, allowing precise control of the mixing process.

Hygienic design

Made of stainless steel or other food-grade materials to ensure compliance with hygienic standards in industries such as food and pharmaceuticals.

Scalability

V-blenders are available in a variety of sizes, from laboratory scale to mass production units. This scalability allows for seamless transitions between different production volumes and consistent blending results.

| Type | Swept Volume(L) | Total Volume(L) | Mixing Power(kw) |

| VH-2 | 0.8 | 2 | 0.04 |

| VH-5 | 2 | 5 | 0.55 |

| VH-8 | 3.2 | 8 | 0.55 |

| VH-10 | 4 | 10 | 0.55 |

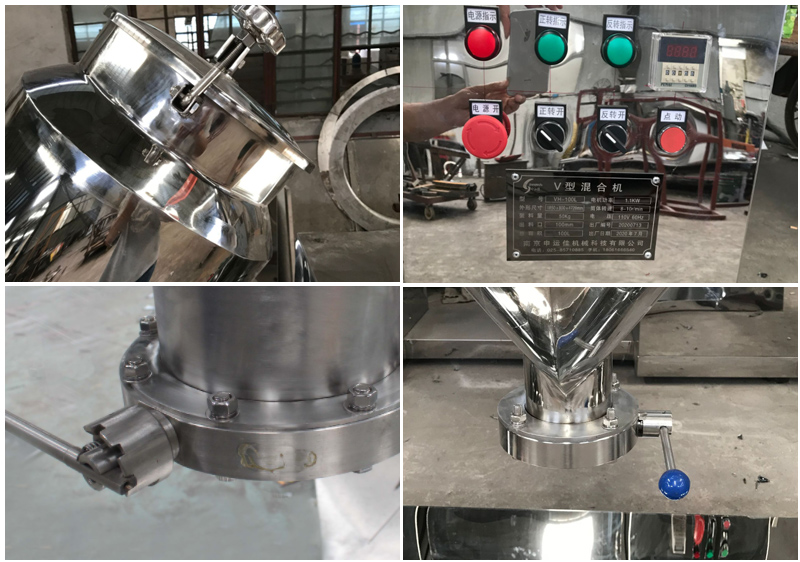

Machine body and rotating tube: Made entirely of high quality 304 stainless steel for easy cleaning and disinfection in accordance with GMP standards.

Inside the tube and screw mixing: Smooth polishing, no blockage, no dead ends, convenient for post-maintenance.

Outlet: Hygienic butterfly valves ensure no powder leakage during mixing.Polished details, in line with GMP Standards.

Operation switch: Easy to operate, can control mechanical mixing time and speed, etc.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.