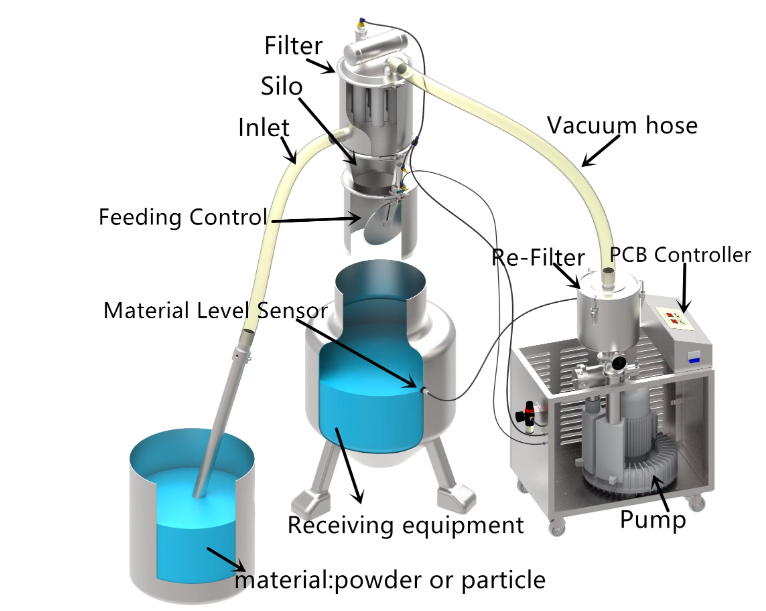

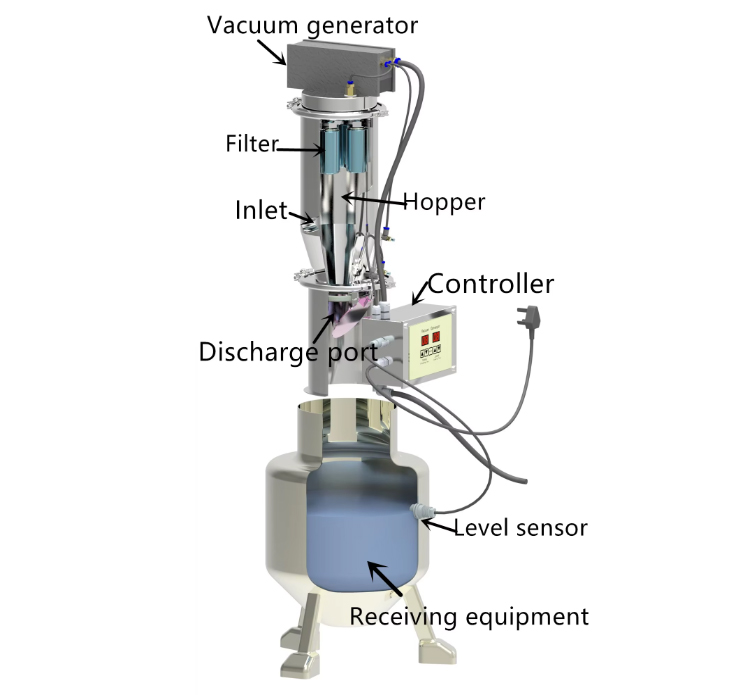

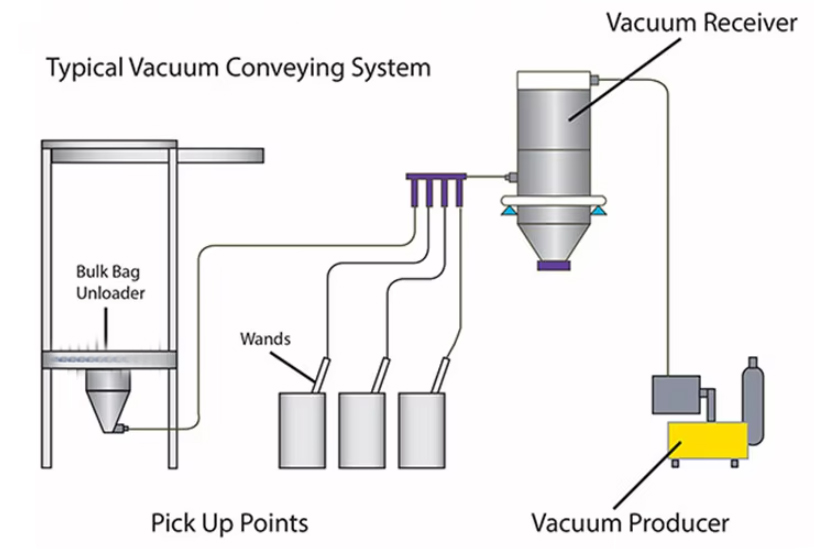

Powder vacuum feeder is a dust-free closed pipeline conveying equipment that uses vacuum suction to convey particles and powdered materials. It generates vacuum through a vacuum pump, and uses the air pressure difference between the vacuum and the ambient space to form gas flow in the pipeline, drive the powdered material to move, and thus complete the powder delivery.

The vacuum feeder can be used to directly feed materials from containers into mixers, reactors, hoppers, tablet presses, packaging machines, vibrating screens, granulators, wet granulators, dry granulators and pulverizers. The machine reduces the labor intensity of workers and eliminates dust pollution.

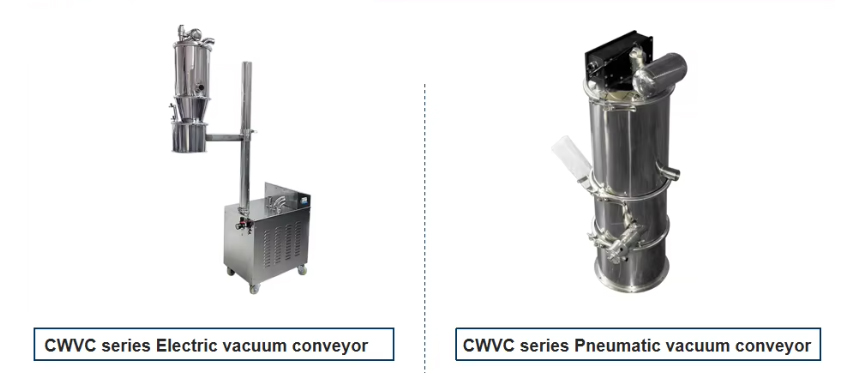

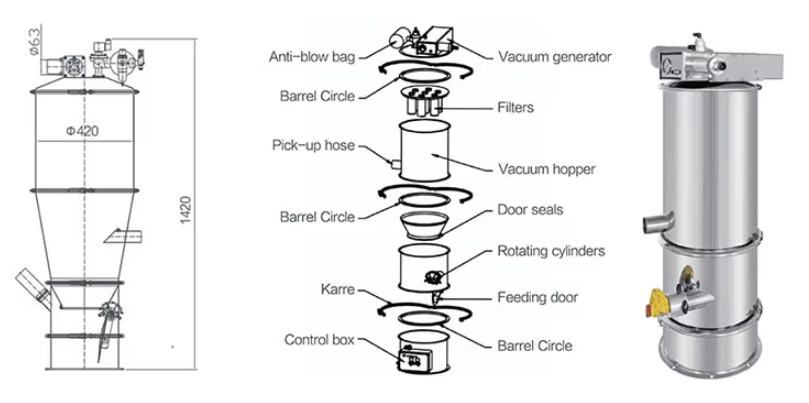

The working principle of the powder vacuum feeder is to generate negative pressure through high-pressure blowers, Roots blowers, water ring vacuum pumps and other equipment, and use the air pressure difference to drive the material to move, forming a vacuum logistics. The material is sucked into the vacuum feeder through the pipeline by negative pressure. In the feeder, the filter element isolates the material from the negative pressure air. After the negative pressure stops, the material is discharged by its own weight and enters the next process. At the same time, the positive pressure starts backblowing when the material is discharged, blowing off the material attached to the surface of the filter element. After the discharge and backblowing are completed, the discharge valve is closed, and the negative pressure and feed valve are opened for the next suction process.

Powder vacuum feeders are widely used in various light and heavy industrial industries such as chemical, pharmaceutical, food, metallurgy, building materials, and agricultural and sideline products. It is particularly suitable for conveying sensitive materials that cannot be exposed to ambient air, such as raw material powder, chemical powder, metal oxide powder, etc. Due to its pipeline transportation characteristics, powder transportation in a small space can be completed.

Material properties: Make sure the feeder is suitable for handling specific properties of powder materials, such as fluidity, abrasiveness, and moisture content.

Capacity and throughput: Choose a feeder with appropriate capacity to meet the production requirements of your factory.

Cleaning and Maintenance: Choose a feeder with easy-to-clean components and easy maintenance to ensure operational efficiency.

System Integration: Consider how the powder vacuum feeder integrates with existing equipment and processes in your production line.

Safety and Compliance: Ensure the feeder meets industry safety, sanitation, and regulatory compliance standards.

Powder vacuum feeders are a valuable asset in industries that require efficient and hygienic conveying of powdered materials. By utilizing vacuum technology, these feeders are clean, efficient, and versatile, making them a must-have for material handling applications across a variety of industrial sectors.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.