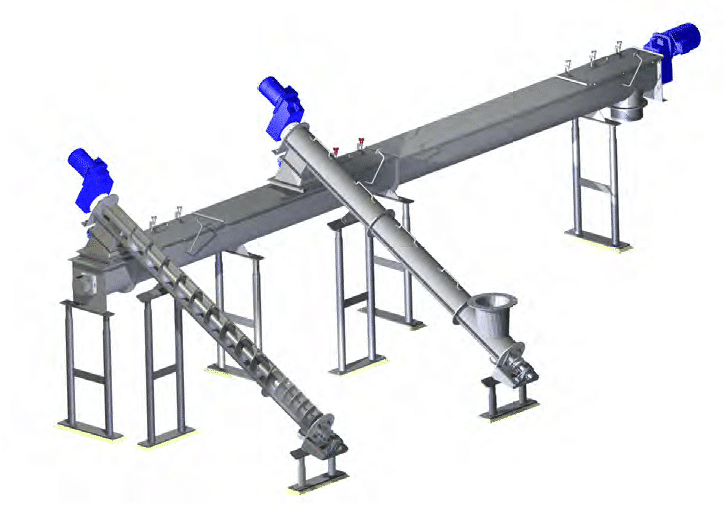

Multiple linkage screw feeders

The multiple screw feeder is a device that uses several coordinated screw shafts (typically 3–5) to transport and feed materials. Developed from the traditional single screw feeder, it enhances conveying efficiency through multi-shaft design and synchronized control.

![]()

![]()

![]()

-

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Conveying capacity: 1.4-244 cubic meters/hour

Conveying length: 4-70 meters

Highlights:

Feeding amount can be controlled

No material jamming, no arching, smooth discharge

It also has the functions of conveying, sealing, homogenizing and stirring

What are Multiple linkage screw feeders?

Screw feeder is an automatic equipment commonly used in industrial production. It can accurately transport raw materials to the production line according to a certain amount and speed, improving production efficiency and quality. Multiple linkage screw feeder is a system composed of multiple screw feeders, which can run multiple screw feeders at the same time to improve production efficiency and flexibility.

Multiple linkage screw feeders refer to a combination of equipment that links multiple screw feeders through an intelligent system to achieve collaborative work. This combination of equipment can improve production efficiency, reduce labor costs, and is suitable for production lines that require a large amount of material feeding. Multiple linked screw feeders can also be seamlessly connected with other equipment, such as conveyor belts, packaging machines, etc., to realize the automatic operation of the entire production line.

In multiple linkage screw feeders, each feeder can be uniformly operated and monitored through a centralized control system. Different feeding time and speed can be set to meet the needs of different production environments. When one of the feeding machines is finished loading, the intelligent system will automatically transfer the next material to be processed to the next feeding machine, realizing a continuous workflow.

What are the multiple linkage screw feeders used for?

As a multifunctional material conveying and feeding equipment, the multiple screw feeder plays an important role in many industries. It is widely used in the food processing industry to process various food raw materials such as flour and grains; in the chemical industry, it is used to convey powdered and granular materials such as fertilizers and plastic granules; in the building materials industry, it is responsible for the feeding of bulk raw materials such as cement and sand; in the agricultural field, it provides efficient transportation for feed, seeds, etc.; in the pharmaceutical industry, it accurately feeds pharmaceutical raw materials and powders; in the packaging industry, it is also often used to convey plastic granules, paper and other packaging materials. This fully demonstrates the wide applicability of the multi-linkage screw feeder in handling diversified materials and adapting to the needs of different industries.

Multiple linkage screw feeders can be used in various industries, such as food processing, chemical industry, medicine, mining, etc. It can adapt to a variety of different material conveying requirements, including various powder, granular, flake and block materials. And it can also adapt to different conveying distances and conveying angles, and can realize conveying in different directions such as horizontal, inclined and vertical.

How does the multiple linkage screw feeders work?

The operating principle of multiple linkage screw feeders is to suck the material from the discharge port into the spiral groove through the rotation of the screw shaft, and then push the material forward along the spiral groove through the rotation of the spiral groove, and finally pass the discharge port to the designated location. Multiple screw feeders can realize simultaneous transmission of multiple materials and improve production efficiency. Moreover, the number and location of the screw feeders can be flexibly adjusted according to production needs to adapt to different production situations.

Classification of multiple linkage screw feeders

Multiple linkage screw feeders can be divided into two categories according to their shell shape: U-shaped and tubular. These two types of feeders differ in structure, applicable materials, and output to meet different process requirements.

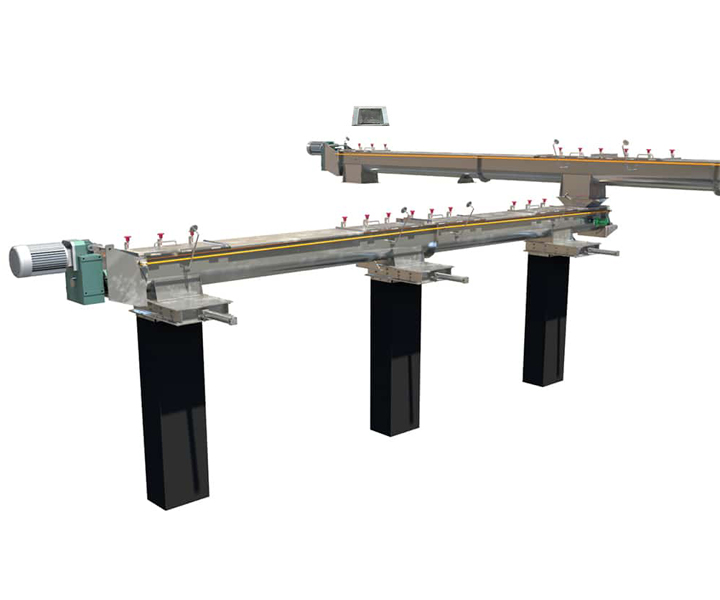

U-shaped screw feeder

Structural features: The U-shaped linkage screw feeder adopts an open trough with a U-shaped cross-section or a removable cover. Multiple screw shafts are installed side by side in the U-shaped trough and rotate in coordination through a linkage device.

Applicable materials: Suitable for powdered, small granular and block materials with general or poor fluidity, such as mixed mortar, lime powder, some pigment powder, dry chemical intermediates, mixed fertilizers, etc.

Output size: For small and medium-sized U-shaped linkage screw feeders, the output of general powdered materials may be between 5m³/h and 30m³/h. For large models or materials with higher density, the output may reach 50 m³/h or even more than 100 m³/h.

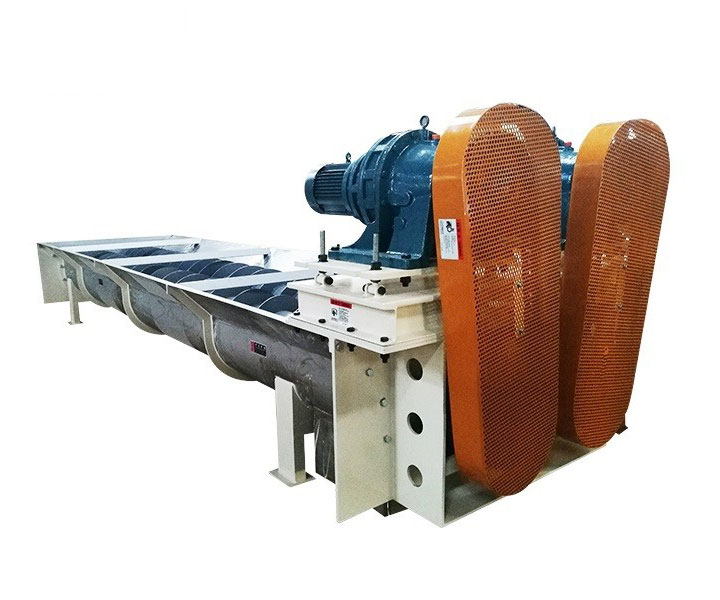

2. Tubular linkage screw feeder

Structural features: The tubular linkage screw feeder adopts a circular tubular closed shell. Multiple screw shafts are installed in the tubular shell and driven by a linkage device. The biggest feature of this structure is fully enclosed transportation, which can effectively prevent dust leakage and material contamination.

Applicable materials: Especially suitable for powdered and small granular materials with good fluidity, such as limestone, high-purity chemical powder, pharmaceutical powder raw materials, powdered additives, etc.

Output size: The output of small and medium-sized tubular linkage screw feeders may be between 3m³/h and 20m³/h. For large-sized equipment or when processing materials with very good fluidity, the output may also reach 30m³/h to 80m³/h.

What are the advantages of multiple linkage screw feeders?

Precise batching: Multiple linkage screw feeders ensure precise and consistent material feeding, resulting in uniform detergent cake quality and avoiding variations in product composition.

Improved efficiency: By automating the feeding process, Multiple linkage screw feeders reduce manual labor and improves the overall production efficiency of the detergent cake plant.

Cost savings: Multi-Auger Feeder's precise feeding mechanism minimizes material waste, reduces production costs and maximizes profitability.

Easy integration: Multiple linkage screw feeders can be seamlessly integrated into existing detergent cake production lines, enhancing the functionality of the entire system.

The advantage of multiple linkage screw feeders is that it can save labor costs and improve production efficiency. It can automatically complete the conveying work of materials, reducing the input of manpower and labor intensity. Moreover, multiple linked screw feeders can run multiple screw feeders at the same time, which improves production efficiency and production capacity, and meets the needs of mass production.

At the same time, multiple linkage screw feeders can also improve the flexibility and stability of production. It can flexibly adjust the number and position of screw feeders according to changes in production conditions to meet the conveying requirements of different materials. Moreover, linkage operation can be realized between multiple screw feeders to ensure the stability and reliability of the entire system.

To sum up, multiple linkage screw feeders are an automatic equipment that can improve production efficiency and quality. It can adapt to the conveying requirements of various materials, flexibly adjust the quantity and position, and improve the flexibility and stability of production. Through the linkage operation of multiple screw feeders, the simultaneous transmission of multiple materials can be realized, and the production efficiency and production capacity can be improved.

Technical parameter table of multiple linkage screw feeder

| Parameter item | LS-100 | LS-200 | GX-300 | WLS-400 (shaftless) |

| Conveying capacity (t/h) | 2-8 (horizontal) 1-5 (inclined) | 5-15 (horizontal) 3-10 (inclined) | 8-25 (horizontal) 5-18 (inclined) | 10-30 (viscous material) |

| Screw diameter (mm) | 100 | 200 | 300 | 400 |

| Speed (r/min) | 20-120 | 20-100 | 15-80 | 10-60 |

| Motor power(kW) | 1.5-4 | 3-7.5 | 5.5-15 | 7.5-22 |

| Conveying length (m) | ≤30 (single unit) | ≤40 (single unit) | ≤50 (single unit) | ≤35 (shaftless) |

| Tilt angle (°) | 0-20 | 0-15 | 0-10 | 0-5 |

| Applicable materials | powder, granules | powder, granules, small pieces | granules, small pieces, wear-resistant materials | viscous, wet materials, easy-to-wind materials |

| Shell material | carbon steel/stainless steel | carbon steel/stainless steel | manganese steel (wear-resistant) | stainless steel |

Manufacturer of multiple linkage screw feeder

Dahan Machinery focuses on the research and development and manufacturing of powder and granular material conveying equipment. Its products are widely used in chemical, food, medicine, building materials, environmental protection and other fields. The company takes technological innovation and customized services as the core to provide efficient and stable conveying solutions.

Multi-axis linkage design: multiple screw shafts work together to achieve long-distance and large-flow conveying of materials, which is suitable for complex working conditions (such as multi-point feeding and multi-point unloading).

Efficient energy saving: optimize the screw structure and drive system, reduce energy consumption, and improve conveying efficiency, especially suitable for continuous production lines.

Customized service: screw diameter, speed, material (such as stainless steel, carbon steel) and other parameters can be customized according to material characteristics and process requirements.

Dahan Machinery provides one-stop service from scheme design, equipment production to installation and commissioning, and is equipped with a professional after-sales team to ensure stable operation of the equipment. If you need to learn more about the product details or get a quote, you can contact the official website of Dahan Machinery or contact our sales department.(My whatsapp: +86 15236742901,e-mail: sale@xxdahan.com)

Recommend Product

Address:China,Yanjin county forest park gate to the west 1000 meters north road.

Email

Email