Overview

In the flour processing industry, different materials (cereals, meal, flour, bran) are milled, fed, weighed, and partly mixed together, including additives, to obtain different types of flour. Dahan Machinery manufactures specialized equipment for the processing, dust removal, feeding, conveying, interception, mixing and bulk loading of flour, additives and by-products to ensure performance, durability and simple, fast and clean maintenance.

Solution

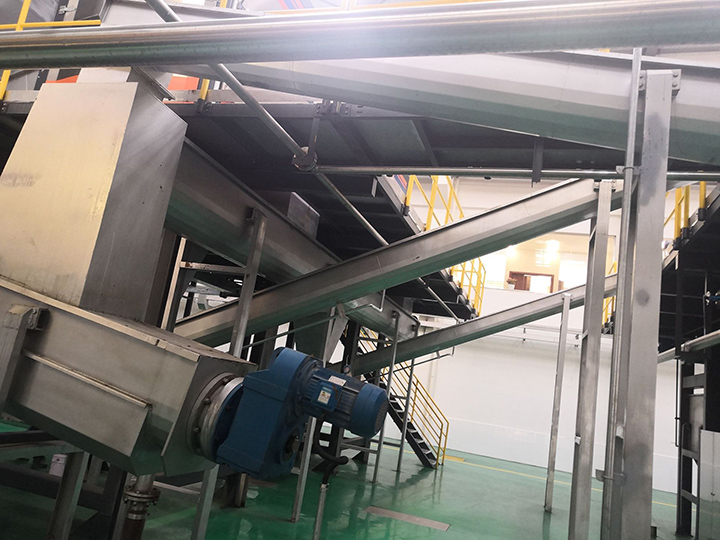

Dahan manufacturer recommends stainless steel auger conveyor

The main advantages are as follows:

1. Choose 304 stainless steel material. The auger conveyor made of this material has a smooth appearance, no burrs, and is easy to clean and disinfect. For the food industry, it can meet its hygienic standards and can ensure that the flour will not be contaminated during the conveying process.

2. The conveying capacity is up to 458 cubic meters per hour, which can be divided into 11 different types of auger conveyors.

3. The conveying angle is divided into three types: horizontal, vertical and inclined. The suitable conveying angle is selected according to the conveying requirements of different users. The layout is more flexible and the adaptability is strong.

Feedback

High degree of automation, low energy consumption and stable operation can not only reduce maintenance costs, but also considerable production benefits.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.