Molybdenum concentrate for screw conveyor is a type of material handling equipment designed to move molybdenum concentrate from one point to another within a processing facility. Molybdenum concentrate is a valuable mineral product obtained from the processing of molybdenum ores and is used in various industrial applications, including steel production, chemical manufacturing, and more.

Screw Conveyor: The central component of the system, the screw conveyor consists of a helical screw blade that rotates within a trough or tube. This rotating screw efficiently moves the molybdenum concentrate along the conveyor length.

Trough or Tube: The trough or tube serves as the housing for the screw blade and provides a contained pathway for the molybdenum concentrate to be transported.

Drive System: The drive system, usually powered by an electric motor, provides the necessary rotational force to drive the screw blade and move the molybdenum concentrate along the conveyor.

Support Structure: The support structure provides stability and rigidity to the conveyor system, ensuring smooth and reliable operation.

Loading: Molybdenum concentrate is loaded into the inlet of the screw conveyor, typically at the lower end of the trough.

Transportation: As the screw blade rotates, it pushes the molybdenum concentrate along the length of the conveyor towards the discharge end.

Discharge: The molybdenum concentrate is discharged at the outlet of the screw conveyor, where it can be further processed, stored, or transferred to the next stage of the production process.

Efficiency: Screw conveyors are known for their high conveying efficiency, allowing for the rapid and continuous transport of molybdenum concentrate.

Reliability: These conveyors are robust and reliable, with minimal downtime, ensuring consistent operation in demanding industrial environments.

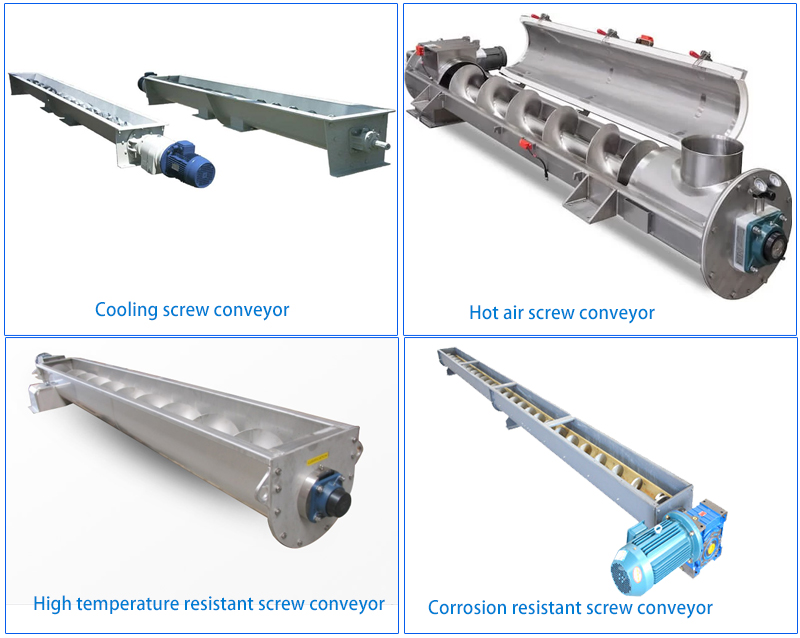

Flexibility: Screw conveyors can be customized to suit specific processing requirements, including varying capacities, lengths, and configurations.

Safety: Properly designed screw conveyors help maintain a safe working environment by containing the molybdenum concentrate within the conveyor system.

Transportation: Moving molybdenum concentrate from processing units to storage facilities or transportation vehicles.

Mixing and Blending: Incorporating molybdenum concentrate into other materials for further processing.

Feeding Equipment: Supplying molybdenum concentrate to downstream equipment, such as flotation cells or drying units.

Molybdenum concentrate for screw conveyor plays a vital role in the efficient handling and transportation of molybdenum concentrate in mining and mineral processing operations. Understanding its components, operation, advantages, applications, and maintenance requirements can help optimize the performance of this essential equipment in the industry.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.