The small screw conveyor is small and light, easy to move, occupies a small space, and has a relatively low price, which is especially suitable for users who have little requirements for conveying output.

The above table is the parameter table of LS/GX type small screw conveyor.

It can be seen that the conveying capacity of the same type of conveyor with different speeds and powers will also be different. Therefore, if there is a more accurate requirement for the conveying capacity when selecting a conveyor, in addition to the conveyor model, it is also necessary to consider the power, Speed and other considerations.

Φ in the rotational speed is the material filling coefficient, and Φ=0.33 in the table indicates that the materials used in the test are medium abrasive materials, such as coal, ash, cement, etc.

Choose:

| LS Model | 100 | 160 | 200 | 250 |

| GX Model | 200 | 250 | ||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 |

| Pitch(mm) | 100 | 160 | 200 | 250 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 |

| Throughput QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 |

| Power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 |

| Power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 |

| Throughput QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 |

| Power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 |

| Power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 |

| Throughput QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 |

| Power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 |

| Power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 |

| Throughput QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 |

| Power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 |

| Power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 |

Type

GX type small screw conveyor has two models of 200 and 250 to choose from, which are used for horizontal, inclined and vertical one-way conveying.

LS type small screw conveyor has four types: 100, 160, 200 and 250. It is improved on the basis of GX screw conveyor, which increases the passing area of materials, makes the passing of materials more and more circulated, and improves the conveyance. ability. It is used for one-way conveying with horizontal or inclination angle less than 20.

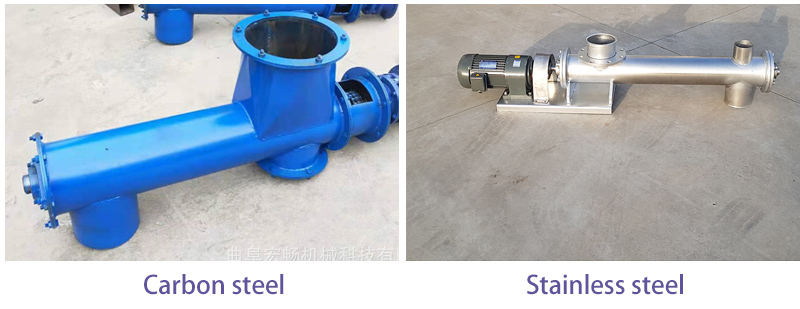

Material

Small screw conveyors are mainly divided into two types: carbon steel and stainless steel. Stainless steel conveyors have significantly higher acid and alkali corrosion resistance and high temperature resistance than carbon steel materials, and can also avoid equipment rusting and causing pollution to materials. When materials are corroded Choose stainless steel when it has high temperature resistance, high temperature or high hygienic requirements

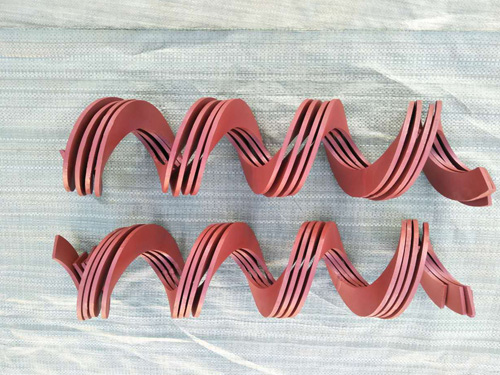

blade

The helical blades of small screw conveyors can be mainly divided into three categories: solid helical surface, belt helical surface and paddle helical surface.

Solid helical surface: simple structure, strong conveying capacity, suitable for conveying dry granular or powdery materials with good scatter, and is the most widely used blade type.

Belt helical surface: the helical pitch is the same as the diameter of the helical blade, which is suitable for conveying powdery and small pieces of material.

Paddle-type helical surface: mainly used to transport materials with high viscosity and compressibility. This kind of screw blade has and completes the functions of mixing and mixing materials at the same time in the process of completing the transportation operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.