Stainless steel screw conveyor is a special conveying equipment for the food industry. Below we focus on the application of some stainless steel screw conveyors in food and beverage related processes.

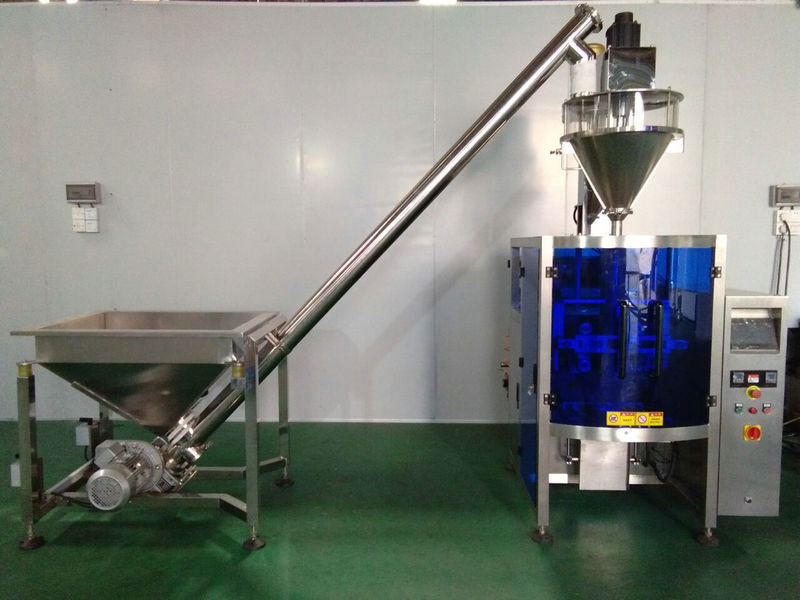

Food stainless steel screw conveyors are commonly used in food powder processing applications to handle and transport various food powders, such as flour, sugar, spices and milk powder, and can be used to transfer food powders from storage tanks to processing equipment. For example, conveying flour from a storage tank to a mixing tank. It can also be used to convey food powder to packaging equipment such as filling machines or bagging machines. Food Stainless Steel Screw Conveyors can be designed to adjust the flow rate of the conveyed powder to match the speed of the packaging equipment.

Food stainless steel screw conveyors can be used in various applications of food raw materials for handling, mixing, sorting, drying, cooling and transportation, for handling and transporting various raw materials such as grains, fruits, vegetables, meat, etc. Used to transfer raw materials from storage bins to processing equipment, or to transport raw materials between different processing equipment or different areas of a processing facility.

In the process of turning barley and wheat into a satisfying pint of beer, breweries need to move large quantities of hops from storage plants into large brewing tanks, where they are filled with water and the fermentation process begins. The auger does an excellent job of efficiently metering hops and grains during the brewing process, the included auger is able to move the material without degrading the product, thus preserving the rich flavor and aroma present in the product.

Dairies often turn excess milk into powdered milk -- which has a longer shelf life than liquid milk. To achieve this goal, milk powder processors need a hygienic system that can efficiently transport their products. Stainless steel screw conveyors can be used to move powders and degrade products throughout a facility, but their length and space-demanding nature make them unsuitable for processors with smaller facilities.

For smaller facilities, inclined screw conveyors are an excellent choice, allowing plants to make the most of space without giving up any basic hygiene requirements. In addition, there are food hygiene standards to ensure that raw materials are not polluted during transportation.

Are Stainless Steel Screw Conveyors Right for Your Food Industry? Stainless Steel Screw Conveyors feature easily controlled variable speeds, hygienic and customizable designs to meet the needs of various food and beverage manufacturers. Depending on the facility and the specific products you handle, we can provide you with custom designs.

The following are customer cases of screw conveyors in the food industry:

| Client | Case 1 | Case 2 | Case 3 |

| An american grain manufacturer | A spice manufacturer in india | A frozen food manufacturer in Europe | |

| Require | Used to transport various types of grain from storage bins to mixing tanks. | Manufacturers were looking for a way to automate the spice mixing process to increase efficiency and reduce labor costs. | A solution was needed for transporting frozen vegetables from the freezer to the processing line. |

| Solution | They chose to install a series of custom-designed screw conveyors made of food-grade stainless steel to handle different types of grain. The screw conveyor is designed with a special mixing screw to ensure that the grain is thoroughly mixed before being transferred to the mixing tank. | They chose to install a custom-designed food stainless steel auger conveyor system that can handle multiple spice ingredients and transfer them to a mixing tank. The screw conveying system is designed with a special mixing screw to ensure that the spices are fully mixed before being transferred to the mixing tank. | We chose to install a custom designed screw conveyor system that can handle frozen vegetables without damaging them. The auger conveyor system features a hollow auger design that allows cold air to circulate to keep the vegetables frozen during transport and is also designed with a dust cover to prevent contamination during transport. |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.