Electrostatic fine powders plastic screw conveyor is a device specially used to transport electrostatic fine powder plastics. It transports fine powder plastics from one location to another through spiral rotation, and is suitable for the transportation and processing of fine powder plastics in the plastics industry.

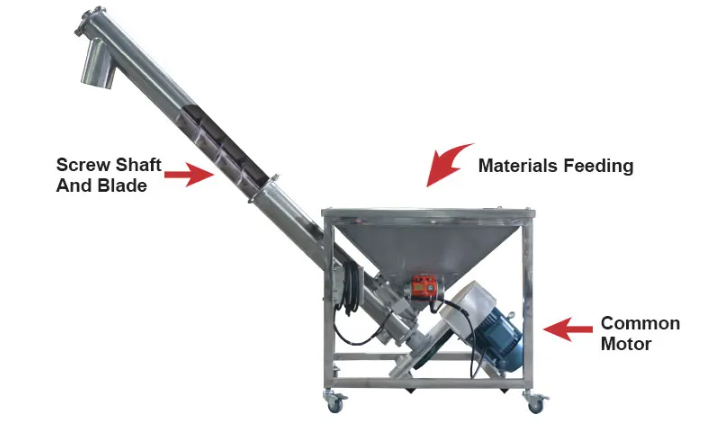

The working principle of the Electrostatic fine powders plastic screw conveyor is based on screw conveying technology. It consists of a spiral shaft, spiral blades, conveying pipes, etc. When working, the spiral shaft drives the spiral blades to rotate and transport the electrostatic fine powder plastic from the feed port to the discharge port. By adjusting the spiral speed and the inclination angle of the conveying pipe, the conveying speed and flow rate of fine plastic plastic can be controlled.

Anti-static design: Static fine powder plastic easily generates static electricity during transportation, causing powder adhesion and blockage. In order to solve this problem, the electrostatic fine powder plastic screw conveyor adopts an anti-static design, such as using conductive materials to make transportation pipes and setting conductive ground wires, etc., which effectively reduces the generation and accumulation of static electricity.

Efficient transportation: The screw conveyor uses the continuous rotation of the spiral blades to achieve a continuous and stable transportation process. It can efficiently transport finely powdered plastic from one location to another, improving production efficiency.

Flexible adaptability: The electrostatic fine powder plastic screw conveyor is suitable for conveying different powder materials. Conveying pipes and blades of different materials can be selected according to specific requirements. At the same time, it can also adjust the conveying speed and flow rate according to process requirements to meet different production needs.

Simple structure: The electrostatic fine powder plastic screw conveyor has a simple structure, few components and easy maintenance. It does not require complex control systems, is simple to operate, and reduces equipment failure and maintenance costs.

Plastic powder production: In the production process of plastic powder, raw materials or finished powder need to be transported to different processes or storage warehouses. The electrostatic fine powder plastic screw conveyor can realize fast and stable transportation of powder and improve production efficiency.

Plastic product processing: During the processing of plastic products, fine powder plastic needs to be transported to injection molding machines, extruders and other equipment for processing. The electrostatic fine powder plastic screw conveyor can accurately transport fine powder plastic to the designated location, ensuring the continuity and stability of the production process.

Plastic recycling and reuse: In the plastic recycling and reuse process, fine plastic powder needs to be transported to crushers, granulators and other equipment for processing. The electrostatic fine powder plastic screw conveyor can transport the recycled fine powder plastic to the corresponding equipment to realize the reuse of resources.

Electrostatic fine powders plastic screw conveyor has the characteristics of anti-static design, efficient transportation, flexible adaptability and simple structure. It is widely used in the plastics industry for the transportation and processing of fine powder plastics

Electrostatic fine powders plastic screw conveyors are mainly used to convey electrostatically sensitive or easily adhered fine powders materials (such as plastic particles, powders, etc.). According to different structures and application scenarios, they are mainly divided into the following categories:

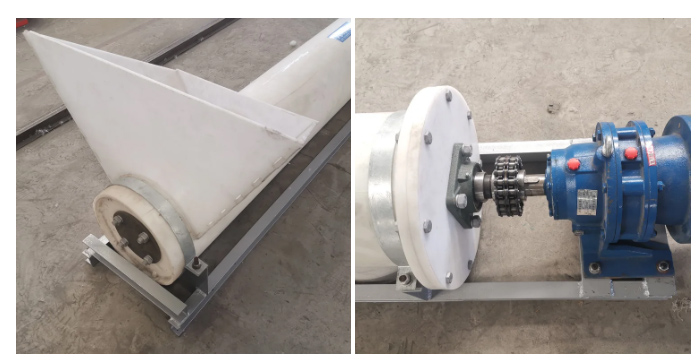

1. Trough screw conveyor

Features: The conveying trough is U-shaped or semicircular, with a simple structure and easy maintenance, suitable for horizontal or small angle conveying.

Applicable scenarios: Short-distance conveying of electrostatically sensitive or easily adhered fine powders plastic particles. Suitable for occasions with small conveying volume and short conveying distance.

1. Tube screw conveyor

Features: The conveying pipe is a closed round pipe to prevent material leakage and dust flying, and can achieve horizontal, inclined or vertical conveying.

Applicable scenarios: Closed conveying of electrostatically sensitive or easily adhered fine powders plastic particles, suitable for occasions with high environmental protection requirements and need to prevent material pollution.

1. Shaftless screw conveyor

Features: No central shaft design, the spiral blades are directly fixed in the conveying pipe to avoid material entanglement and blockage, suitable for conveying viscous and easily entangled materials.

Applicable scenarios: Conveying fine powders plastic particles that are sensitive to static electricity or easy to adhere, especially materials with high viscosity, suitable for sewage treatment, chemical industry, food and other industries.

4. Double screw conveyor

Features: The double screw structure has stronger conveying capacity and smoother operation, suitable for large-capacity and long-distance conveying.

Applicable scenarios: Large-capacity conveying of fine powders plastic particles that are sensitive to static electricity or easy to adhere, suitable for occasions requiring efficient conveying.

4. Vertical screw conveyor

Features: Specially used for vertical or large-angle conveying, compact structure, small footprint, suitable for short-distance lifting of materials.

Applicable scenarios: Vertical conveying of fine powders plastic particles that are sensitive to static electricity or easy to adhere. Applicable to occasions where space is limited and materials need to be lifted.

Features: With wheels or tracks, it can be flexibly moved, suitable for temporary conveying tasks.

Applicable scenarios: Short-distance transportation of fine powders plastic particles that are sensitive to static electricity or easy to adhere, suitable for occasions such as construction sites and temporary yards that require flexible movement.

When choosing an electrostatic fine powders plastic screw conveyor, the key factors to consider are: the type and amount of material to be moved, the distance to be covered and your plant layout. Dahan Machinery has accumulated rich experience in the field of screw conveyors, providing a variety of standard and customized powders conveying method options for the food, chemical and plastic industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.