Screw conveyor is a mechanism that uses a rotating screw blade, usually in a pipe, to move liquid or granular materials. The LS and GX types of screw conveyors are widely used, but the distinction between the two is not clear. This article We will analyze the difference between LS type and GX type screw conveyor for you.

1. Structure

The difference between GX type and LS type screw conveyor mainly lies in the position of bearing support. Both ends of GX support bearing are close to the casing or stuck in the casing, which will lead to inconvenient installation and replacement of bearings or maintenance of bearings, and may also come into contact with materials. If it is not strict, it will enter the bearing, causing the bearing to run inflexibly.

The LS does not have this problem. Both ends of the bearing are outside the shell, and there are suitable bearing supports, which are convenient for maintenance or replacement, and the material can pass through more smoothly.

2. Conveying volume

The screw diameter of GX type screw conveyor includes 150, 200, 250, 300, 400, 500, 600mm, 3 meters when the body is short, up to 70 meters when the body is long, the level difference is 0.5 meters, and the conveying capacity per hour reaches 1.2 -458m³.

The LS type screw conveyor screw diameter includes 100, 160, 200, 250, 315, 400, 500, 630, 800, 1000, 1200mm, divided into single drive and double drive, the length of single drive can reach 40 meters (large 30 meters meter), the double drive adopts the intermediate break shaft structure, the length can reach 80 meters (60 meters for extra large), the step difference is 0.5, and the conveying volume per hour is 5.6-93m³.

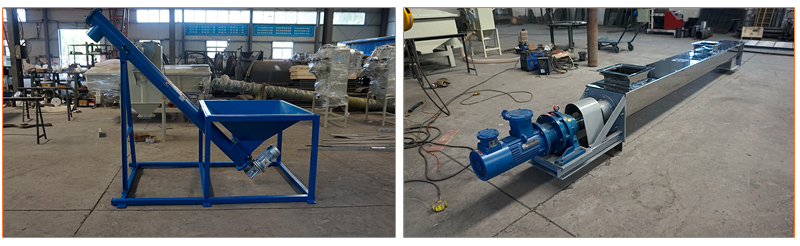

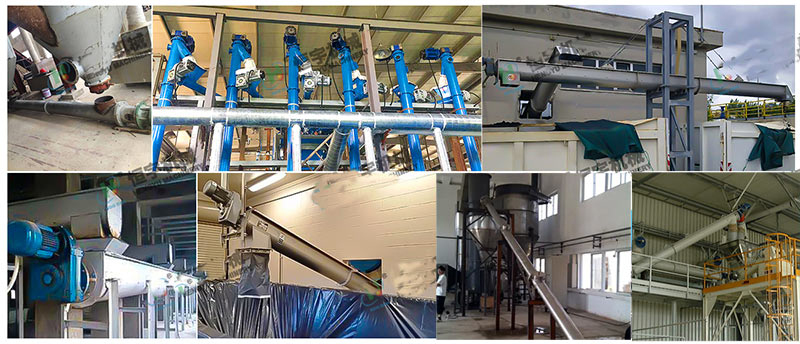

LS Screw Conveyor

GX Screw Conveyor

LS Screw Conveyor Specifications:

| Model |

Diameter (mm) |

Rated speed (r/min) |

Reference capacity (m³/h) |

Motor power (Kw) |

Admission biggest gradient (o) |

| LS114 | 114 | 84-130 | 1 | 0.75-18.5 | <60 |

| LS133 | 133 | 84-130 | 1.3 | ||

| LS159 | 159 | 84-130 | 5 | ||

| LS219 | 219 | 84-130 | 15 | ||

| LS245 | 245 | 84-130 | 20 | ||

| LS273 | 273 | 84-130 | 30 | ||

| LS315 | 315 | 84-130 | 40 | ||

| LS400 | 400 | 60-100 | 45 | ||

| LS500 | 500 | 60-100 | 70 | ||

| LS600 | 600 | 60-100 | 100 |

GX Screw Conveyor Specifications:

| Model | GX150 | GX200 | GX250 | GX300 | GX400 | GX500 | GX600 |

|

Spiral diameter (mm) |

150 | 200 | 250 | 300 | 400 | 500 | 600 |

|

Pitch (mm) |

120 | 160 | 200 | 240 | 320 | 400 | 480 |

|

Speed (rpm) |

31-129 | 31-114 | 31-102 | 31-88 | 31-88 | 31-75 | 31-59 |

|

Delivery capacity (m3/h) |

1.3-5.5 | 3.1-11 | 6-20 | 10-30 | 25-71 | 49-118 | 185-162 |

| Allowable kW speed ratio | 0.013 | 0.03 | 0.06 | 0.1 | 0.25 | 0.48 | 0.85 |

|

Allowable cantilever load (Kg) |

210 | 370 | 580 | 800 | 1500 | 2400 | 3500 |

3. Conveying angle

The two types of screw conveyors are generally arranged horizontally or obliquely. The conveying inclination of the LS type screw conveyor does not exceed 15°. If the angle exceeds 20°, the GX type screw conveyor should be selected.

The above three points are the main differences between the LS type screw conveyor and the GX type screw conveyor. In short, GX type and LS type screw conveyors are more or less different, and users need to decide which conveying equipment to use according to the actual situation.

| Screw diameter | (mm) | 150 | 200 | 250 | 300 | 400 | 500 |

| Pulverized coal | n | 190 | 150 | 150 | 150 | 118 | 97 |

| Q | 9 | 17 | 33 | 58 | 108 | 170 | |

| Cement | n | 97 | 75 | 75 | 60 | 60 | 47.5 |

| Q | 3.1 | 5.6 | 11 | 15 | 36 | 55 | |

| Soda ash | n | 118 | 95 | 95 | 75 | 75 | 60 |

| Q | 4.5 | 8 | 16 | 53 | 84 | ||

| n: speed (rev/min), Q: conveying capacity (m³/h) | |||||||

Address:China,Yanjin county forest park gate to the west 1000 meters north road.