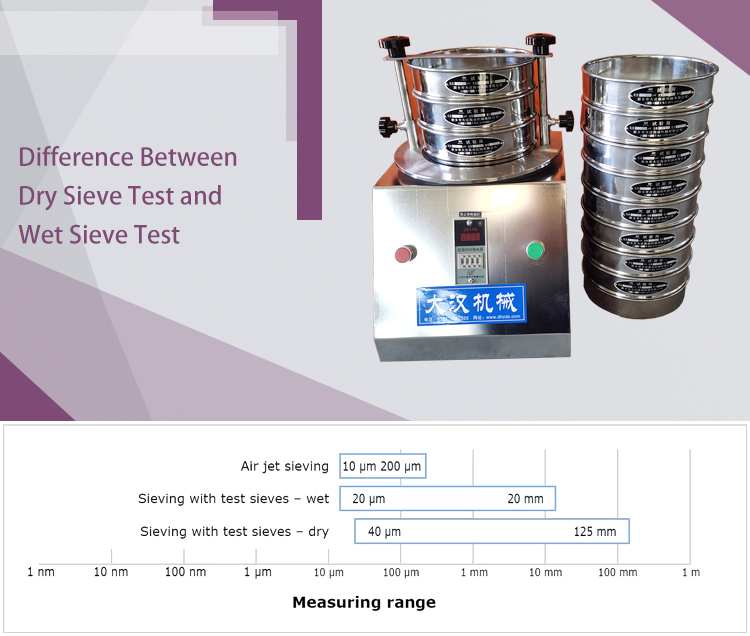

Sieve test is divided into two different types of wire mesh sieves: dry sieve test and wet sieve test, so what is the difference between the two, I hope this article can help you better understand and make a reasonable choice.

1. The Dry sieve test is suitable for drying or conventional sieving to determine the particle size of dry, free-flowing materials. These sieves are used by shaking or vibrating the sieve, which allows the particles to seek openings in the wire mesh. The particles are able to separate themselves. Chemical, food and beverage, pharmaceutical and other industries use "dry" test sieves.

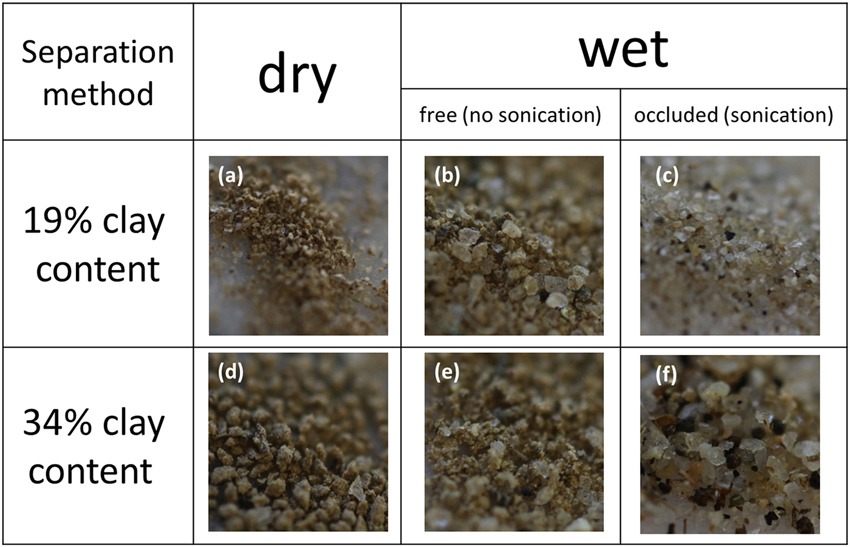

2. Wet sieve test is a particle size grading series using a liquid substance, the method is to apply a liquid (usually water) to the test sample and pass the fine particles through the screen while classifying the agglomerates, and then the sample Dry and evaluated, wet sieving is suitable for samples with a high concentration of fine particles or samples whose particles are not easily broken down by mechanical shaking. For example, clays, such as clay or silt, can clump together to form larger particles that cannot pass through the mesh.

Wet sieve test can only be performed on the following materials:

- not soluble in water

- Unaffected by water: e.g. expanded solids do not work

- Stable up to 230°F (110°C)

Typical application:

-Soil and mineral aggregates with high fines content

-Fragile but insoluble materials such as coal or other minerals

- Light powder

-Sludge and Glaze

-Kaolin and fillers

-Abrasive

- Microparticles

Dry sieve test is available in the following diameters: 3", 6", 200mm, 8", 10", 300mm, 12" and 18".

Wet sieve test is available in the following diameters: 3", 8", 12".

| Dry Classification | Wet Classification | |||

| Size fraction,um | Wt.,% | Cum. wt.,retained % | Wt.,% | Cum. wt.,retained % |

| +600 | 11.74 | 11.74 | 1.32 | 1.32 |

| - 600+ 106 | 79.76 | 91.50 | 87.28 | 87.28 |

| -106+45 | 2.37 | 93.87 | 2.53 | 91.13 |

| -45+25 | 0.98 | 94.85 | 1.42 | 92.55 |

| -0.025 | 5.15 | 100.00 | 7.45 | 100.00 |

| Total | 100.00 | 100.00 | ||

Dry sieve test is divided into half-height and full-height sieves. Half-height sieves can be used in sieve shakers to allow more sieves to fit in the sieve stack on your machine.

Wet sieve tests are all manufactured with a height of 4 inches, which allows more space for the sample when you add wet solutions.

The most important thing to remember when choosing a test sieve is that your material and particle size is always the best place to start, if you have any questions about dry and wet sieving, please feel free to contact Dahan Machinery and we will be very happy to work with you on these issues.

1. How to perform wet sieve analysis?

Dry the sample to constant weight and weigh to the nearest 0.1 g

If your sample mixes easily with water:

- Place the sample on the best test sieve and wash it back and forth with a gentle stream of water from the hose (make sure no sample is lost)

- The entire sieve containing wet material should be dried in the oven if possible. It is critical that the temperature does not exceed 230°F (110°C)

- After the material has dried thoroughly, the material should be weighed and repeated on the next coarser sieve **Drying time depends on the properties of the material and should be determined by a series of weight checks at intervals until no significant change occurs)

- Weigh your samples and analyze them

If your material does not mix well with water

- Place the weighed sample in a quart jar. Fill the jar about three-quarters full with water.

- Shake the jar vigorously to thoroughly mix the granules with the water. Then pour this mixture over the sieve and continue the washing process as instructed in step 3. **Your jar should be rinsed more than once.

2.How to perform dry sieve analysis?

Step 1: Take a representative dried sample weighing approximately 500 grams.

Step 2: If the granules clump or clump, use a pestle and mortar to break up the clumps, but not the granules.

Step 3: Accurately determine the mass-weight (g) of the sample.

Step 4: Prepare a stack of test sieves. The sieves are stacked in order, with the largest aperture at the top and the smallest at the bottom. A receiver is placed under all sieves to collect samples.

Step 5: Weigh all sieves and pans separately.

Step 6: Pour the sample from Step 3 onto the top of the sieve stack and close the lid, place the stack into the sieve shaker and secure the clips, adjust the timer to between 10 and 15 minutes, then turn on the shaker.

Step 7: Stop the shakers and measure the mass of each sieve and retained soil/material.

1. When dry sieving does not produce a sufficient degree of sample separation

2. When testing samples containing small amounts of gravel-sized material

3. When silt and clay need to be removed

Address:China,Yanjin county forest park gate to the west 1000 meters north road.