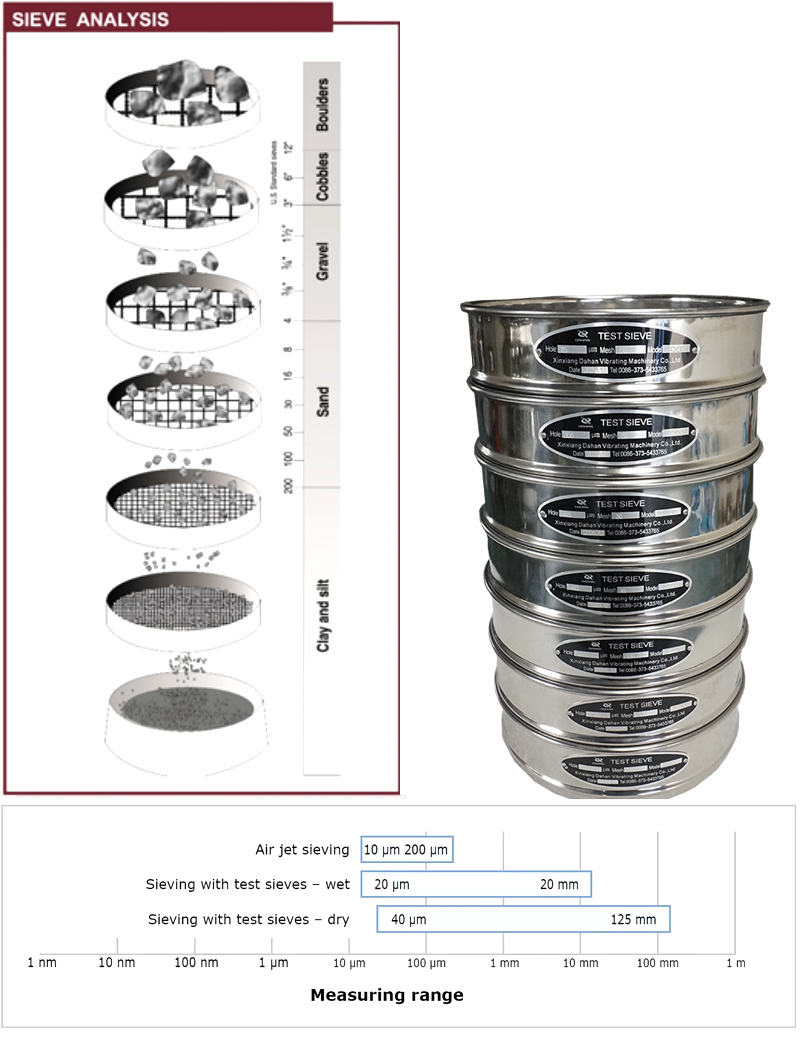

For particle size inspection of dry, free-flowing materials 4.75 mm and above

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Price:$20.00-$3,680.00/Set/Set

Consult now and enjoy a 10% discount

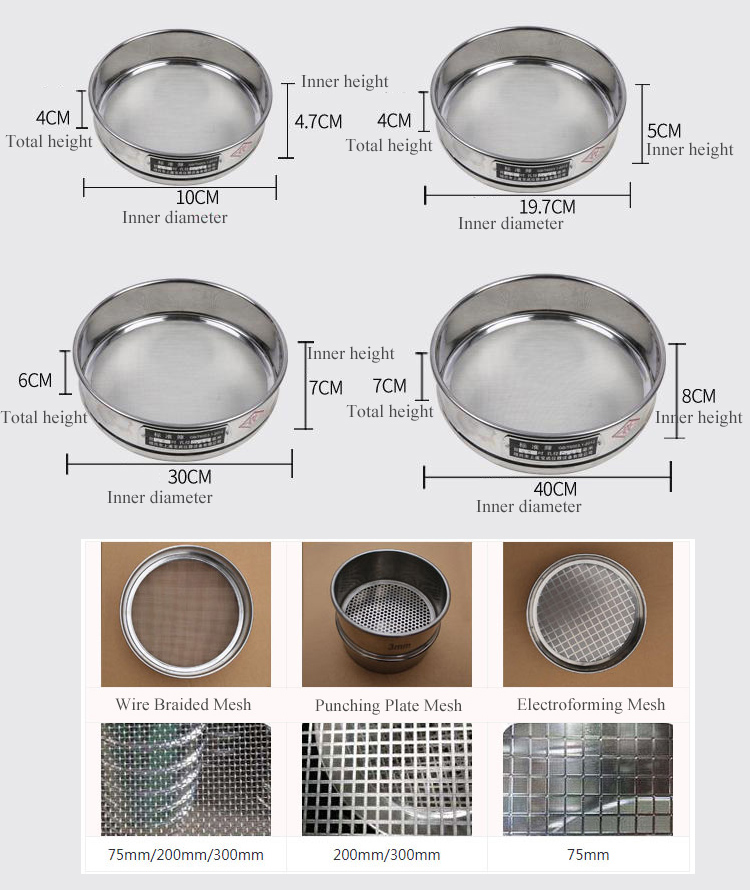

Diameters:3", 6", 200mm, 8", 10", 300mm, 12" and 18".

Screen size: 40 µm - 125 mm

Weight:60kg

Height:Half-height and full-height sieves

Material:Stainless Steel 304 / Brass / Nylon

Application: particle size structure analysis and detection of granular and powdery materials under dry conditions

Commitment:

Dry sieve test, also called dry sieve analysis test, is used to determine the particle size of dry, free-flowing material, which determines the size distribution of aggregate particles in a given sample. These sieves are used by shaking or vibrating the sieve, which allows the particles Look for openings in the wire mesh. The particles are able to separate themselves. During the test, the sample is sieved through a series of screens with different apertures, removing particles above a certain size.

Dry sieve test is suitable for samples with larger particles and dryness, and is widely used in construction materials, chemical industry, food, pharmaceutical and other fields. Through dry sieve test, experimenters can quickly and accurately understand the particle distribution of the sample, helping them conduct particle analysis, quality control and process improvement, thereby improving production efficiency and product quality.

Dry sieve test and wet sieve test are both methods used for particle analysis. The difference lies in the state of the sample processed. Dry sieve test is suitable for dry granular or powder samples, and the particle size distribution is analyzed through a sieve; wet sieve test is suitable for wet or sticky granules, which are sieved after adding water or other liquids. Wet sieve test is usually used for the analysis of particles under wet conditions and can evaluate the particle size distribution and fluidity of particles.

Dry sieve test and wet sieve test are two different particle screening methods commonly used in laboratories or industrial production.

Dry sieve test:

Material state: In the dry sieve test, the sieving particle material is dry and has no attached liquid or moisture.

Sieving conditions: It is usually carried out at room temperature and does not involve liquid media.

Purpose: It is mainly used to evaluate the particle size distribution, screening efficiency and screening capacity of the particle material, and is often used for the screening of dry materials such as powders and particles.

Wet sieve test:

Material state: In the wet sieve test, the particle material contains a certain amount of liquid or moisture, which is usually achieved by soaking or adding liquid.

Sieving conditions: The effect of liquid needs to be considered, and the particle material is screened under the action of liquid. Purpose: Mainly used to evaluate the screening performance of granular materials under wet conditions, such as the screening of wet coal, wet sand and other granular materials.

| Dry Classification | Wet Classification | |||

| Size fraction,um | Wt.,% | Cum. wt.,retained % | Wt.,% | Cum. wt.,retained % |

| +600 | 11.74 | 11.74 | 1.32 | 1.32 |

| - 600+ 106 | 79.76 | 91.50 | 87.28 | 87.28 |

| -106+45 | 2.37 | 93.87 | 2.53 | 91.13 |

| -45+25 | 0.98 | 94.85 | 1.42 | 92.55 |

| -0.025 | 5.15 | 100.00 | 7.45 | 100.00 |

| Total | 100.00 | 100.00 | ||

In dry sieve test, dry sieve test is available in the following diameters: 3", 6", 200mm, 8", 10", 300mm, 12" and 18". These sieves of different diameters are suitable for screening granular materials with different particle size ranges.

Dry sieve is divided into half-height and full-height sieves.

Half-height sieve: Half-height sieve uses half-height sieve in the screening process. It is suitable for occasions where fast screening is required, and the particle size distribution of particles can be obtained in a shorter time, especially for situations where the particle distribution range is narrow.

Full-height sieve: Full-height sieve is another common dry sieve test screening method, that is, full-height sieve is used in the screening process, and particles can be screened within the entire sieve height range. It is suitable for situations where more accurate particle analysis and particle size distribution are required, and can provide more detailed screening results.

Vibration sieving: The sample is thrown upwards by the vibration of the sieve bottom and falls back due to gravity. The amplitude represents the vertical oscillation height of the screen bottom. Due to this combined movement, the sample material is evenly distributed over the entire sieve area. The particles are accelerated in the vertical direction, spin freely, and fall back in the statistical direction. In RETSCH vibrating screens, electromagnetic drives move the spring/mass system and transmit vibrations to the screen stack. The amplitude can be continuously adjusted to a few millimeters.

Horizontal screening: In the horizontal screen vibrating screen, the screen moves in a horizontal circle in the plane. Horizontal sieves are preferably used for needle-shaped, flat, elongated or fibrous samples. Due to the horizontal screening motion, hardly any particles change their orientation on the screen.

Tapping screening: In the tapping screen vibrator, the horizontal circular motion is superimposed with the vertical motion generated by the tapping pulse, and the tapping motion imparts greater impact force to the particles. Therefore, for some materials, such as abrasives, The proportion of fine particles is usually higher.

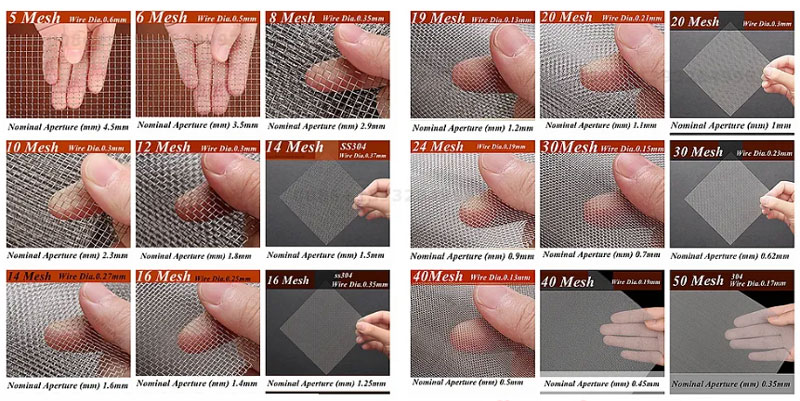

Mesh Size: The mesh size refers to the size of the holes on the screen, usually expressed as the number of meshes (mesh), such as the number of meshes per inch. Smaller meshes are suitable for screening fine particles; larger meshes are suitable for screening coarse particles.

Mesh Type: Screens can be divided into different types according to different materials and structures, such as metal screens, rubber screens, etc.

Screening Time: Indicates the time required for screening operations, affecting screening efficiency and production efficiency.

| Product Name | dry sieve test 20/50/80/100 micron test sieve for laboratory filtration |

| Material | Stainless Steel 304/316/316L,copper,brass |

| Micron size | 8 mesh --2000 mesh |

| Aperture | 0.02mm - 100mm |

| Used | testing screening, and filter, testiing filter and screen |

| Frame diameters | 75mm/ 100mm/200mm/300mm/ 400mm |

In dry sieve tests, sieving size refers to the maximum and minimum size range of particles passing through the screen.

Maximum Particle Size: Indicates the maximum particle size that can pass through the screen. Particles exceeding this size will be retained on the screen.

Minimum Particle Size: Indicates the minimum particle size that can pass through the screen. Particles smaller than this size will pass through the screen.

Target Particle Size Range: Indicates the target particle size range required in experiments or production.

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

Dry sieve test sieves play an important role in scientific research, production, laboratories and quality inspection rooms in the fields of medicine, chemical industry, metallurgy, geology, etc. It is used for screening, filtering and testing of particles, powders and liquid materials to help optimize product quality and production efficiency.

In the field of medicine, it can be used for drug particle analysis; in chemical industry, it is used for raw material screening; in metallurgy, it is used for ore screening; in geology, it is used for rock particle analysis.

| Cassia | 14 mesh | Buckwheat | 12 mesh | Tenebrio molitor eggs | 12 mesh |

| Worm dung | 30 mesh | Soybeans | 4-5 mesh | green beans | 10 mesh |

| Rice | 12-14 mesh | rice flour | 30-40 mesh | Cornmeal | 30-40 mesh |

| flour | 50-60 mesh | Miscellaneous grains | 40-50 mesh | Sesame Millet | 22-24 mesh |

| Fried Chicken Burger Breaded | 20-30 mesh | Mung bean flour | 40-50 mesh | Sesame powder | 40-50 mesh |

| Notoginseng powder | 100-120 mesh | Pine pollen | 100-120 mesh | Chinese medicine powder | 40-50 mesh |

| Oral Chinese medicine powder | 60-80 mesh | Traditional Chinese Medicine Mask | 80-120 mesh | Pearl powder | 120-150 mesh |

| Medicine residue | 60-150 mesh | Soy milk | 80-120 mesh | honey | 80-120 mesh |

| Soup dregs | 120-150 mesh | Tea water | 120-150 mesh | Cooking oil | 150-200 mesh |

Wet sieving and dry sieving are commonly used particle size analysis methods, and the biggest difference between the two methods is the state of the sample. Wet sieving is to suspend the sample in water and separate it through a sieve, which can analyze materials with a particle size of less than 3mm. Dry sieving is to separate completely dry samples through a sieve, which can be used to analyze materials with a particle size greater than 3mm. These two methods can obtain the size distribution of the particle material, which can help us understand the physical properties and preparation process of the sample, and are very useful analytical methods.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.