Copper powder for vibrating screen is a kind of equipment specially used for screening and classifying copper powder. It is widely used in copper powder production and related industries. It achieves efficient screening and classification of copper powder through the combination of vibration force and screen. The following will introduce in detail the working principle, structural characteristics, advantages and application fields of the copper powder vibrating screen.

The working principle of the copper powdervibrating screen is to use vibration force to place copper powder on the screen for screening. During the screening process, the granular materials of copper powder will pass through the aperture of the screen, while the larger particles or lumps of copper powder will be blocked, thus realizing the classification of copper powder of different particle sizes.

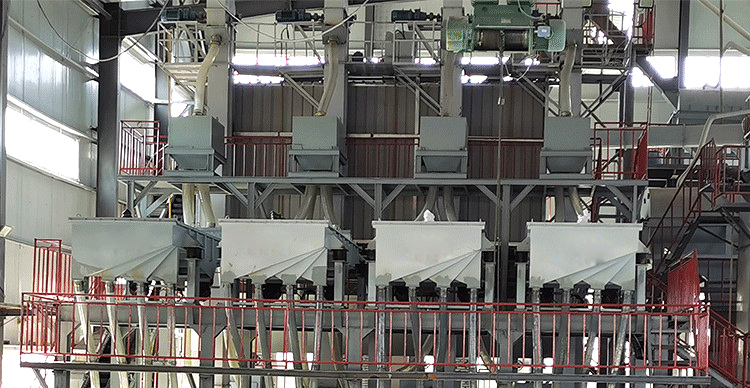

The structure of the copper powder vibrating screen mainly includes a vibration motor, screen box, screen mesh and support structure. The vibration motor provides vibration force to effectively screen the copper powder on the screen. The screen box, as the part that holds the screen mesh and copper powder, is of appropriate size and shape to ensure effective screening. The screen has mesh openings of different pore sizes and is used to separate copper powder of different particle sizes. The support structure provides stable support and vibration transmission to ensure the normal operation of the screening machine.

Efficient screening: The copper powder vibrating screen uses the combined effect of vibration force and screen mesh to efficiently screen and classify copper powder and improve production efficiency.

Precise grading: By selecting the appropriate screen aperture, precise grading of copper powder can be achieved to meet different particle size requirements.

Energy saving and environmental protection: The copper powder vibrating screen is driven by a vibration motor, which has lower energy consumption and smaller environmental impact than other screening equipment.

Easy operation: The operation of the copper powder vibrating screen is relatively simple. You only need to control the vibration force and screen aperture to achieve a stable screening effect.

Copper powder vibrating screens are widely used in copper powder production and related industries. Specific application areas include but are not limited to:

Electronic industry: used for screening and grading copper powder to meet the manufacturing needs of electronic components.

Chemical industry: used for grading and screening copper powder to meet the production needs of chemical products.

Metal Processing: Used for the processing and grading of copper powder to improve the quality and performance of metal products.

Decoration industry: used for screening and grading copper powder to produce decorative materials with special effects.

Other fields: Copper powder vibrating screens can also be used in welding materials, coatings, ceramics and other industries to screen and classify copper powder according to specific requirements.

In short, the copper powder vibrating screen is an efficient and accurate screening equipment that is widely used in copper powder production and related industries. Its working principle is simple, its structure is compact, it has the advantages of high efficiency, energy saving, environmental protection and easy operation, providing a reliable solution for the copper powder processing process. By rationally selecting the screen aperture and controlling the vibration force, precise grading and screening of copper powder can be achieved to meet the requirements of different particle sizes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.