As a commonly used screening equipment, vibrating screener is widely used in various industrial fields. It uses vibration force to separate and classify materials according to different particle sizes, and is a key equipment to achieve efficient screening. When choosing the vibrating screener, factors such as material characteristics, screening requirements, and process conditions need to be considered to ensure that the appropriate vibrating screener is selected and improve screening efficiency and product quality.

First of all, it is necessary to understand the characteristics of the materials to be screened. Including factors such as particle size, shape, density, humidity, and viscosity of the material. Different material properties have an important impact on the choice of vibrating screener. For example, for materials with fine particles, it is necessary to choose a vibrating screen with smaller mesh openings to avoid the particles from leaking through the screen. For materials with greater viscosity, you can choose a vibrating screener with a special structure to reduce clogging and adhesion.

Secondly, the screening requirements need to be clarified. Including the required screening accuracy, output requirements, classification requirements, etc. Different screening requirements require different choices of vibrating screeners. For example, for screening tasks that require higher precision, you can choose a vibrating screener with higher vibration frequency and amplitude to improve screening efficiency and precision. For high-throughput screening tasks, vibrating screens with large screen areas and high processing capabilities can be selected.

In addition, process conditions also need to be considered. Including factors such as the installation space of the vibrating screen, power supply requirements, and ambient temperature. The size and form of the vibrating screen should match the process conditions to ensure proper operation and use. At the same time, it is also necessary to ensure that the power supply requirements of the vibrating screener are consistent with the existing power facilities to avoid power supply problems affecting the screening work.

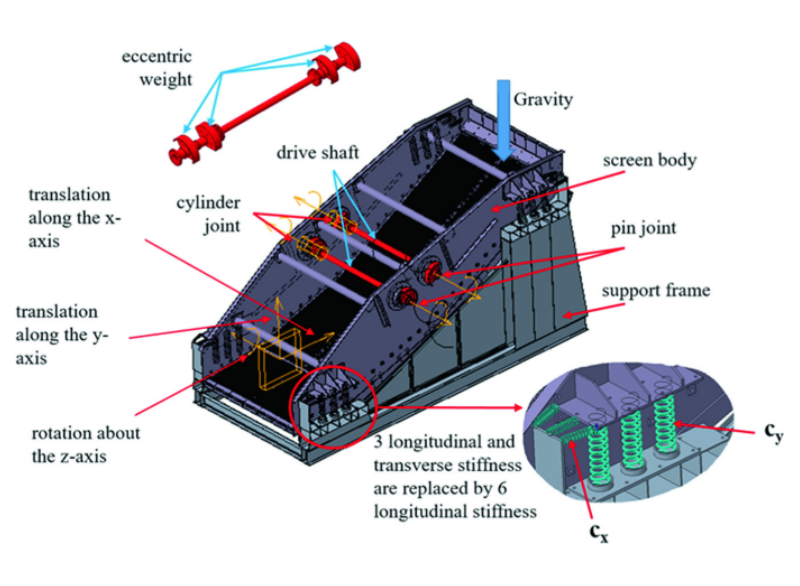

There are many types of vibrating screens to choose from depending on different application requirements. Common types of vibrating screens include linear vibrating screens, circular vibrating screens, elliptical vibrating screens, etc. Each type of vibrating screen has its own characteristics and scope of application. For example, linear vibrating screens are suitable for continuous screening of large quantities of materials; circular vibrating screens are suitable for screening wet and sticky materials; and elliptical vibrating screens are suitable for grading and separating materials.

Finally, when choosing a vibrating screener, you should also consider the reputation and after-sales service of the vibrating screen manufacturer. Choosing well-known and experienced manufacturers can provide more reliable and high-quality vibrating screen equipment. And good after-sales service can provide timely technical support and maintenance to ensure the normal operation and long-term stability of the vibrating screen.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.