The vibrating screener is a device that screens materials through vibration force. It has the characteristics of high efficiency, accuracy and reliability. It is widely used in the screening process of granular materials in various industries.

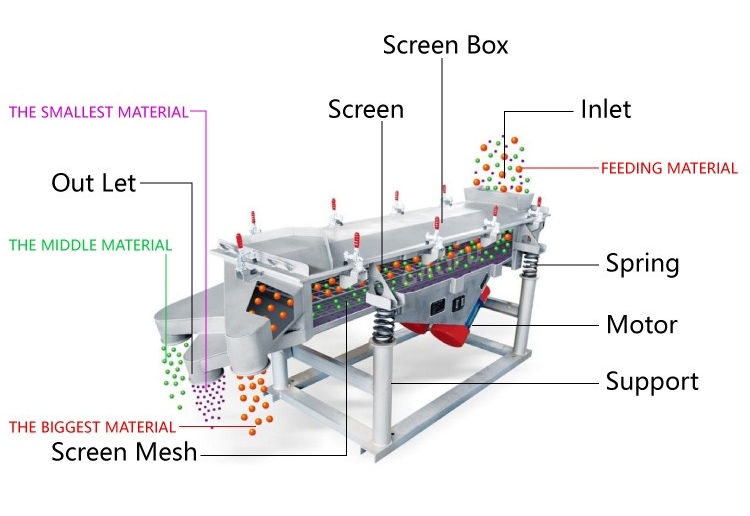

The vibrating screener is mainly composed of screen box, vibrator, spring, eccentric block, etc. When the vibrating screener is working, the vibrator produces horizontal or tilted vibrations in the screen box through the driving device, causing the materials to move relative to the screen surface. Under the action of vibration force, the material gradually stratifies according to the particle size. The larger particles gradually move to the upper part of the screen surface, and the smaller particles fall into the lower layer through the sieve holes. At the same time, the vibration force will also break and clean the blockages in the screen holes, further improving the screening efficiency.

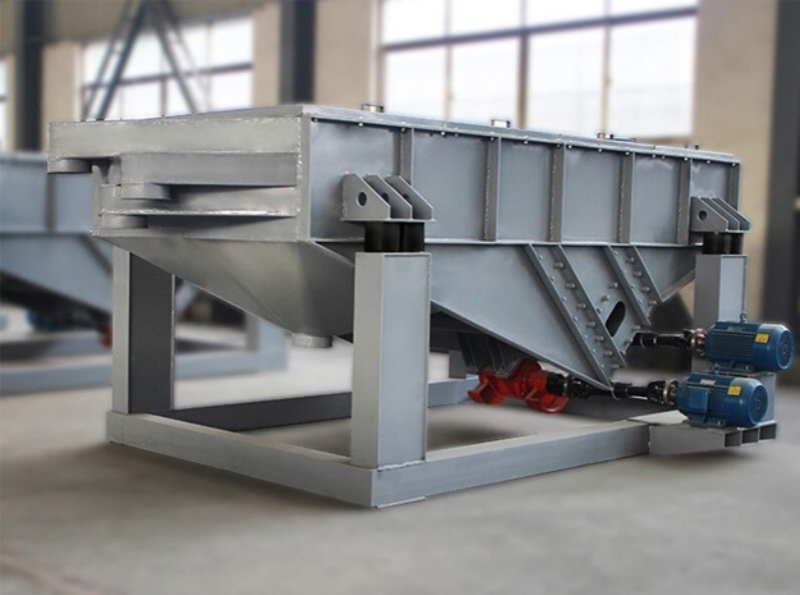

The main structure of the vibrating screen includes screen box, vibrator, spring, eccentric block, etc. The screen box consists of two parts: the upper part and the lower part. The upper part is equipped with a screen, and the lower part is equipped with a vibrator and spring. The vibrator generates vibration force through the eccentric block and transmits it to the screen box. The spring plays a supporting and buffering role to ensure the stability of vibration and the life of the screen. In addition, the vibrating screener is also equipped with auxiliary equipment such as driving devices, guide devices, screen cleaning devices, etc. to improve the screening effect and the stability of the equipment.

Vibrating screens are widely used in mining, metallurgy, chemical industry, building materials and other industries. In the field of mining, vibrating screens are used to screen coarse, medium and fine levels of ores to achieve grading and separation of ores. In the metallurgical industry, vibrating screens are used for screening and dewatering coking coal, slime and other materials to improve efficiency and product quality in the metallurgical process. In the chemical and building materials industries, vibrating screeners are used for screening and classifying chemical raw materials, cement, sand and gravel and other materials to meet the production needs of different particle requirements.

The vibrating screener has the advantages of efficiency, accuracy and reliability. Through the action of vibration force, the screening process of materials can be completed quickly and accurately, improving production efficiency and product quality. At the same time, the vibrating screen has a simple structure, is easy to maintain and clean, and reduces operating costs. With the continuous advancement of science and technology, the automation and intelligence level of vibrating screens are also constantly improving, which will bring more convenience and benefits to the production process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.