Cellulose dry powder screw conveyor is a device for conveying cellulose dry powder. It can effectively transport dry powdered cellulose or other similar materials from one place to another. Dry cellulose powder is a common raw material used in the production of paper, textiles, food and pharmaceuticals, among other industries.

Cellulose dry powder screw conveyor is widely used in many fields. In the chemical industry, it is often used in the production process of cellulose products, such as the transportation of cellulose sheets, cellulose paper, etc. In the food processing industry, it can be used to convey dry powder raw materials of cellulosic components to mixers or packaging machines. In the field of environmental protection, it can be used to treat cellulose particles in waste and realize waste recycling. In addition, the cellulose dry powder screw conveyor is also suitable for the material conveying process in building materials, metallurgy, medicine and other industries.

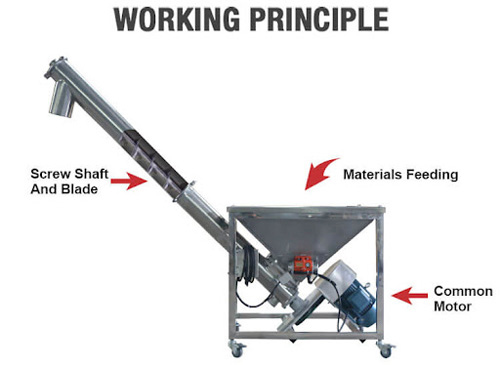

The cellulose dry powder screw conveyor is composed of the main body of the screw conveyor, the driving device, the discharge port and the control system. The main body of the screw conveyor is a long and thin pipe with a screw blade inside. The driving device moves the dry cellulose powder from the feed port to the discharge port by rotating the helical blade.

The working principle of the cellulose dry powder screw conveyor is to use the rotation of the helical blade to push the cellulose dry powder forward. When the spiral blade rotates, it will generate a forward thrust, pushing the dry cellulose powder to move to the discharge port. At the same time, the rotation speed of the helical blade can be adjusted through the driving device to control the conveying speed of the dry cellulose powder.

The cellulose dry powder screw conveyor has a series of advantages. First of all, it has the characteristics of high conveying efficiency and long conveying distance. No matter in the horizontal or inclined direction, this kind of conveyor can smoothly transport the dry cellulose powder to the target position, saving manpower and time costs. Secondly, this kind of conveyor is simple in structure, easy to operate, easy to maintain and clean. The design of the spiral blade makes it difficult for the material to agglomerate or accumulate during the conveying process, reducing the possibility of equipment failure.

In addition to conventional functions, some cellulose dry powder screw conveyors also have some special designs to suit different working environments and needs. For example, some conveyors have a sealed design, which can effectively prevent dust leakage and protect the cleanliness and safety of the working environment. In addition, some conveyors can also be automatically controlled according to needs to realize the monitoring and adjustment of the conveying process.

When using the cellulose dry powder screw conveyor, you need to pay attention to the following points. First of all, place the equipment on a stable ground and keep a certain distance between the equipment and the surrounding environment for maintenance and cleaning. Secondly, it is necessary to regularly inspect and maintain the equipment to maintain the normal operation of the equipment. Finally, pay attention to safety during use to prevent accidents.

In short, the cellulose dry powder screw conveyor is a commonly used material conveying device, which can be widely used in the conveying process of cellulose dry powder. It has the features of high efficiency, stability, low noise and low energy consumption, and plays an important role in the production of related industries. The above is a brief introduction to the cellulose dry powder screw conveyor. If you are interested in it and want to learn more about it, you can directly click to chat online. Welcome your consultation!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.