Vibrating screen springs play an important role in vibrating screen equipment. Their selection directly affects the performance, stability and service life of the vibrating screen. Correctly selecting suitable vibrating screen springs is crucial to the normal operation of vibrating screen equipment. Vibrating screen springs are mainly divided into steel springs, rubber springs and composite springs. So which vibrating screen springs to choose, and how to choose vibrating screens? Xiaobian will introduce you next.

The material selection of the vibrating screen spring is crucial to the performance, durability and stability of the vibrating screen equipment. Different materials have different characteristics, which affect the elasticity, wear resistance and corrosion resistance of the spring. The following will introduce in detail the selection of vibrating screen springs from the material aspect.

a. Steel spring:

Steel springs, as the name implies, are mechanical parts made of metal steel that use elasticity to work.

Advantages: It has long service life and is not affected by ambient temperature.

Applications: vibro sifter, stainless steel vibrating screens, light linear vibrating screens, small heavy vibrating screen, probabilistic screens, etc.

| Model | Inner diameter D (mm) |

Overall height L (mm) |

Steel wire diameter d (mm) |

| Ф70×150×Ф8 | 70 | 150 | 8 |

| Ф70×150×Ф10 | 70 | 150 | 10 |

| Ф70×150×Ф12 | 70 | 150 | 12 |

| Ф70×180×Ф12 | 70 | 180 | 12 |

| Ф70×180×Ф14 | 70 | 180 | 14 |

| Ф70×180×Ф16 | 70 | 180 | 16 |

| Ф70×180×Ф18 | 70 | 180 | 18 |

| Ф76×150×Ф10 | 76 | 150 | 10 |

| Ф36×145×Ф4.5 | 36 | 145 | 4.5 |

| Ф36×145×Ф5.0 | 36 | 145 | 5.0 |

| Ф36×145×Ф5.5 | 36 | 145 | 5.5 |

| Ф36×145×Ф6.0 | 36 | 145 | 6.0 |

b. Rubber spring:

The rubber spring is a high-elastic body. The material is made of ordinary rubber. It is a spring that uses rubber elasticity to cushion and absorb shock.

Advantages: There are excellent cold resistance, air tightness, water resistance, electrical insulation. There are many types of rubber springs in Dahan, and they can be customized as needed.

Applications: Light linear vibrating screens, stainless steel vibrating screen, vibrating feeders, vibrating screen, YA/YK series vibrating screens, etc. Springs of this type are also used in vibration platforms with a bearing capacity of more than 1 ton.

| Model D×H×d (mm) |

Outer diameter D (mm) |

Inner diameter d (mm) |

Height H (mm) |

Working deformation FV (cm) |

Rigidity KL (kg/cm) |

Working load (Pa) |

| Ф50×50×Ф18 | 50 | 18 | 50 | 0.8 | 50 | 80 |

| Ф60×60×Ф20 | 60 | 20 | 60 | 0.8 | 60 | 100 |

| Ф80×80×Ф25 | 80 | 25 | 80 | 0.8 | 100 | 200 |

| Ф80×80×Ф30 | 80 | 30 | 80 | 0.8 | 100 | 200 |

| Ф100×100×Ф25 | 100 | 25 | 100 | 1 | 140 | 500 |

| Ф100×100×Ф30 | 100 | 30 | 100 | 1 | 140 | 500 |

| Ф100×130×Ф30 | 100 | 30 | 130 | 1 | 150 | 550 |

| Ф120×120×Ф30 | 120 | 30 | 120 | 1.2 | 220 | 600 |

| Ф120×140×Ф30 | 120 | 30 | 140 | 1.2 | 230 | 650 |

| Ф127×127×Ф30 | 127 | 30 | 127 | 1.2 | 230 | 640 |

| Ф130×130×Ф30 | 130 | 30 | 130 | 1.3 | 240 | 680 |

| Ф140×140×Ф30 | 140 | 30 | 140 | 1.4 | 300 | 700 |

| Ф140×160×Ф30 | 140 | 30 | 160 | 1.4 | 350 | 680 |

| Ф140×160×Ф40 | 160 | 40 | 160 | 1.4 | 350 | 680 |

| Ф160×160×Ф30 | 160 | 30 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф40 | 160 | 40 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф50 | 160 | 50 | 160 | 1.6 | 350 | 750 |

| Ф160×160×Ф60 | 160 | 60 | 160 | 1.6 | 350 | 750 |

| Ф160×235×Ф40 | 160 | 40 | 235 | 1.6 | 400 | 800 |

| Ф160×240×Ф40 | 160 | 40 | 240 | 1.6 | 400 | 800 |

| Ф180×180×Ф40 | 180 | 40 | 240 | 1.8 | 400 | 800 |

| Ф180×240×Ф40 | 180 | 40 | 240 | 1.8 | 400 | 1000 |

| Ф200×150 | 200 | 150 | 1.5 | 380 | 900 | |

| Ф200×150×Ф65 | 200 | 65 | 150 | 1.5 | 350 | 800 |

| Ф200×200×Ф40 | 200 | 40 | 200 | 2 | 450 | 1000 |

| Ф200×200×Ф50 | 200 | 50 | 200 | 2 | 450 | 1000 |

| Ф200×300×Ф50 | 200 | 50 | 300 | 2 | 480 | 1300 |

| Ф220×220×Ф40 | 220 | 40 | 220 | 2.2 | 500 | 1500 |

| Ф220×220×Ф50 | 220 | 50 | 220 | 2.2 | 500 | 1500 |

| Ф240×240×Ф50 | 240 | 50 | 240 | 2.4 | 550 | 1800 |

| Ф250×250×Ф50 | 250 | 50 | 250 | 2.5 | 580 | 2000 |

| Ф300×245×Ф80 | 300 | 80 | 245 | 1 | 480 | 2800 |

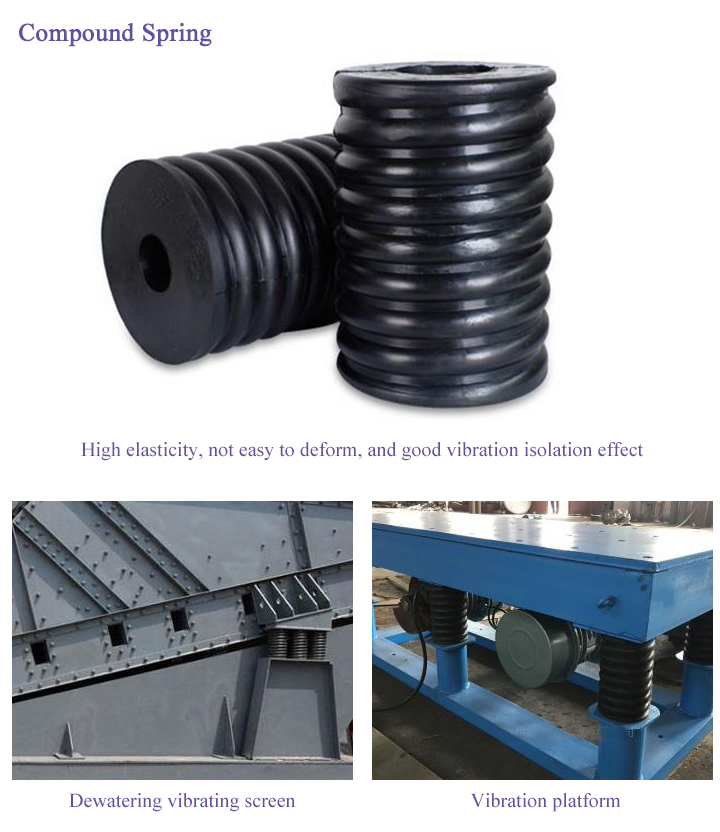

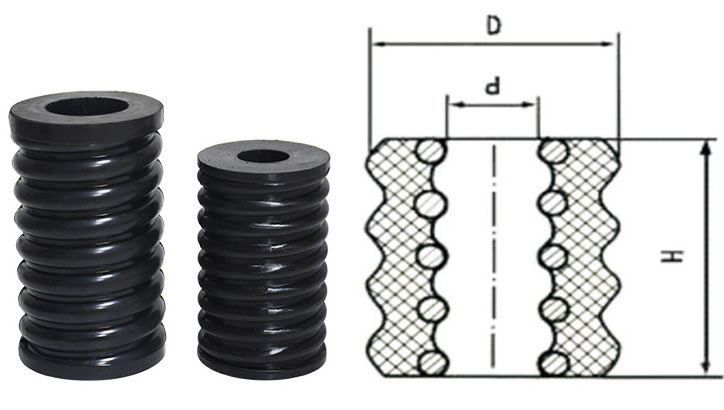

c. Composite spring:

The composite spring is an elastic body composed of a metal coil spring and a rubber composite. It combines the advantages of a metal spring and a rubber spring, and overcomes the shortcomings of both. The shape and mechanical properties are stable, and it can withstand loads and large deformations. Good vibration reduction effect

Advantages: The shape of the composite spring is not limited and has a large elastic deformation.

Application: Suitable for large-scale vibration equipment in mining, coal, metallurgy and other industries.

| Model D×H×d(mm) |

Outer diameter D (mm) |

Inner diameter d (mm) |

Height H (mm) |

Model D×H×d(mm) |

Working deformation FV (cm) |

Rigidity KL (kg/cm) |

Working load (Pa) |

| Ф150×138×Ф55 | 150 | 55 | 138 | 2 | 150—350 | 300—700 | |

| Ф150×150×Ф62 | 150 | 62 | 150 | 2 | 150—350 | 300—700 | |

| Ф150×190×Ф62 | 150 | 62 | 190 | 3 | 180—600 | 500—1800 | |

| Ф150×200×Ф100 | 150 | 100 | 200 | 3 | 180—600 | 500—1800 | |

| Ф150×210×Ф50 | 150 | 50 | 210 | 3 | 180—600 | 500—1800 | |

| Ф150×310×Ф50 | 150 | 50 | 310 | 3 | 180—600 | 500—1800 | |

| Ф150×310×Ф100 | 150 | 100 | 310 | 3 | 180—600 | 500—1800 | |

| Ф180×110×Ф90 | 180 | 90 | 110 | 3 | 180—600 | 500—1800 | |

| Ф180×120×Ф90 | 180 | 90 | 120 | 3 | 180—600 | 500—1800 | |

| Ф180×130×Ф100 | 180 | 100 | 130 | 3 | 180—600 | 500—1800 | |

| Ф180×140×Ф90 | 180 | 90 | 140 | 3 | 240—660 | 700—2000 | |

| Ф180×150×Ф100 | 180 | 100 | 150 | 3 | 240—660 | 700—2000 | |

| Ф180×160×Ф90 | 180 | 90 | 160 | 3 | 240—660 | 700—2000 | |

| Ф180×170×Ф90 | 180 | 100 | 170 | 3 | 240—660 | 700—2000 | |

| Ф180×180×Ф90 | 180 | 90 | 180 | 2—3 | 250—1000 | 750—3000 |

After selecting the material of the vibrating screen spring, it is also important to determine the number of vibrating screen springs. The effective damping device needs to calculate the vibrating screen according to the specifications, output, excitation force and dynamic and static load parameters of the vibrating screen. The number and distribution of springs, if you have such requirements, you must consult a professional vibrating screen manufacturer to obtain professional advice, otherwise the expected shock absorption effect may not be achieved.

The above is an introduction to the vibrating screen spring. If you have other needs, you can always consult us.

1. When designing, the appropriate rubber material should be selected according to the screening material, environment and conditions, as well as the specific gravity of the material itself, static electricity, etc.

2. Attention must be paid to the bonding degree of rubber and metal to avoid stress concentration at the bonding surface;

3. Technically, for shear deformation isolators, in order to improve the service life, an appropriate precompression is usually given in the vertical shear direction, the stiffness in the compression direction becomes harder, and the stiffness in the shear direction becomes soft;

4. If there is resistance, energy must be consumed. This part of the lost energy is converted into heat energy, and rubber is a poor conductor of heat. In order to prevent the performance of the rubber vibration isolator from being affected by excessive temperature rise, the rubber vibration isolator should not be made too large. Structurally, measures that are easy to dissipate heat should be taken, or natural rubber materials with less heat generation should be selected. Because the rubber vibration isolator can convert part of the energy into heat energy, which reduces the vibration energy and achieves the purpose of vibration reduction, the rubber vibration isolator is often called a shock absorber.

5. Regularly maintain and replace the shock absorbing spring, and the vibration isolator should avoid working under tension for a long time.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.