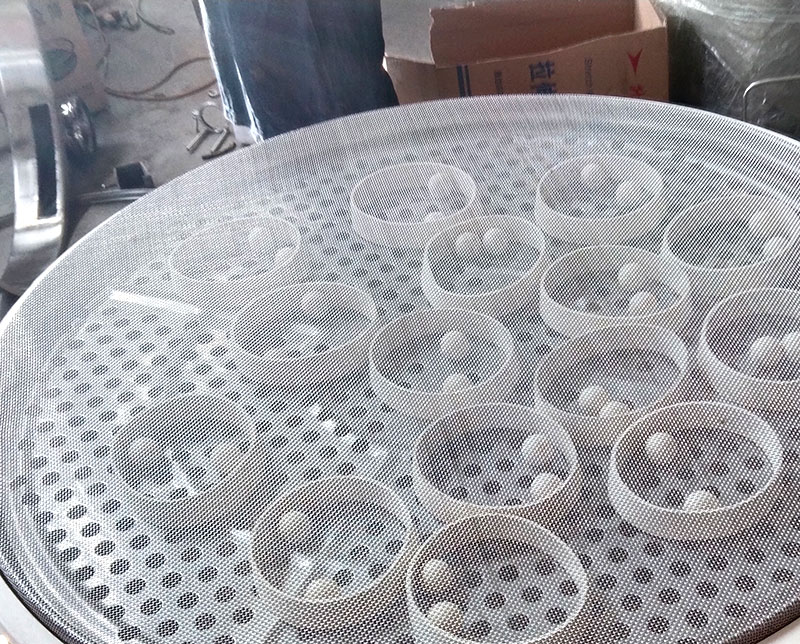

The screen is as fine as 500 mesh or 0.028mm. There are 1-5 layers, and 2-6 kinds can be sorted at the same time. Materials of different specifications.

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers (3 layers is best)

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Motor power: 0.25Kw to 2.2Kw or customized

Application:

Shaker screen is suitable for the particle size classification of granular and powder materials in many industries, and is especially suitable for the classification and disposal of fine particles and micropowders. Using three-dimensional vibration, high-precision sieving and filtering, in the process of high-flow material disposal, it can quickly separate large or small particles with a low percentage, and can quickly separate insoluble substances in various slurries.

1. The sieving is fine to 500 mesh or 0.028mm, and the filtering can reach 5 microns.

2. Net cleaning devices such as bouncing ball and ultrasonic can be used according to the nature of the screened materials to solve the problem of net blocking;

3. 1~5 layers of screens can screen 2~6 kinds of materials with different sizes at the same time;

4. Fully enclosed structure, dust is not easy to fly, and liquid will not splash.

Shaker Screen uses a vertical vibration motor as the excitation source. The rotating motion is converted into horizontal, vertical, and inclined three-dimensional motion through the eccentric weight at the upper and lower ends of the vibration motor, and is transmitted to the screen surface; the material passes through the inlet Entering the equipment, according to different screening requirements, the material passes through 1-3 layers of screens with different meshes. In this process, the screen cleaning devices located under the screens of each layer continue to hit the screens, causing The materials can be screened smoothly and effectively avoid the problem of material blockage. The materials of different meshes pass through the screens of the corresponding meshes of each layer or are discharged through the discharge ports set on each layer to achieve the purpose of screening or filtering. Adjusting the phase angle of the upper and lower ends of the motor can change the movement trajectory of the material on the screen surface.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

The vibrating screen is a commonly used screening equipment. Its main working principle is to separate the materials on the screen surface through the vibration force generated by the motor, and separate the required materials. The screen mesh of the vibrating screen is a key component for separating materials. Its material is generally made of high-quality stainless steel, and has the characteristics of high strength, corrosion resistance, and high temperature resistance.

When using a vibrating screen, the selection of the screen is very important, because different materials need to use screens of different thicknesses to achieve the best screening effect. Generally speaking, the mesh size, shape, quantity, etc. of the screen will have an impact on the screening effect. Therefore, special attention should be paid to the quality and selection of the screen during the purchase and use of the vibrating screen.

Chemical industry: resins, coatings, pigments, rubber, carbon black, activated carbon, co-solvents, glues, sodium sulfate, polyethylene powder, quartz sand, etc.

Medicine: Chinese medicine powder, western medicine powder, medicine raw material powder, etc.

Food: sugar, salt, monosodium glutamate, starch, milk powder, soy milk, fruit juice, rice noodles, dehydrated vegetables, fruit juice, yeast liquid, pineapple juice, fish meal, food additives, etc.

Kiln industry: glass, ceramics, porcelain slurry, abrasive materials, refractory bricks, kaolin quicklime, mica, alumina, calcium carbonate (heavy), etc.

Metal metallurgy: lead powder, zinc oxide, titanium oxide, foundry sand, diamond powder, aluminum powder, iron powder, various metal powders, etc.

Pollution treatment: waste water, waste oil, feces and urine, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.