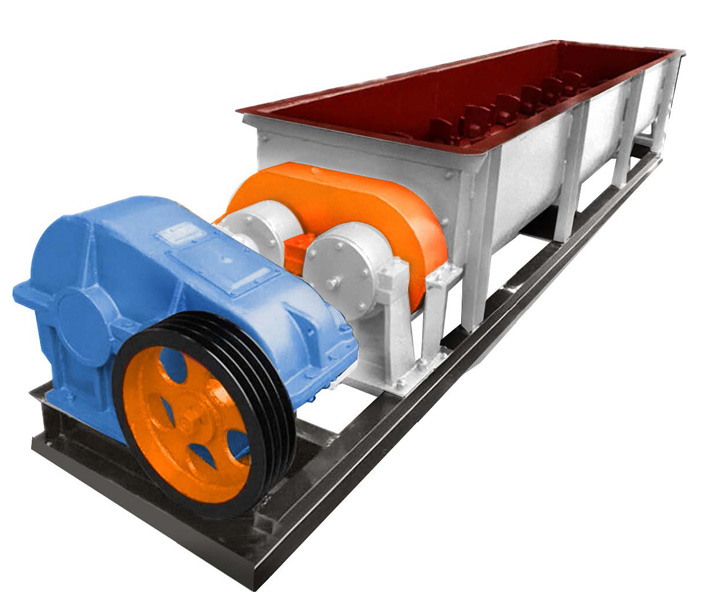

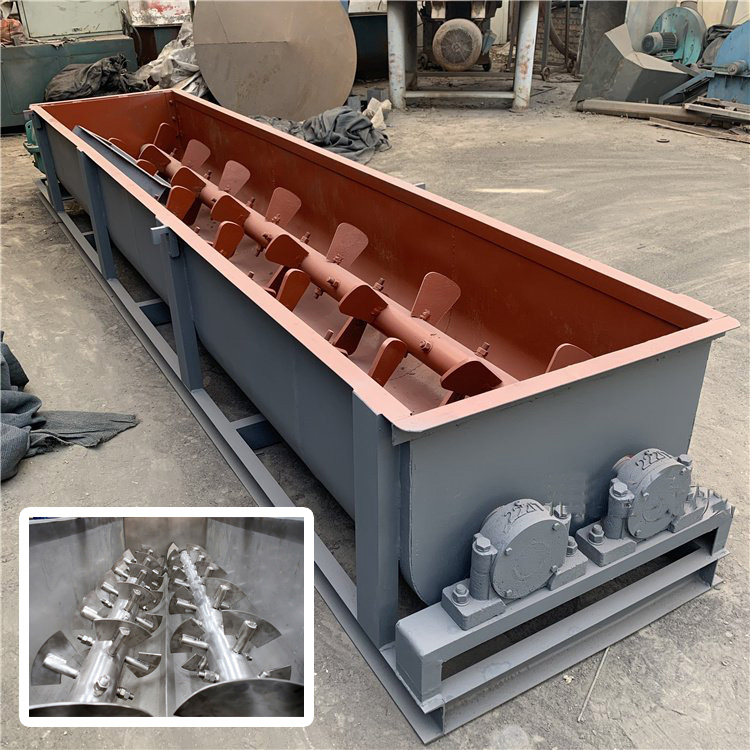

Paddle conveyors are basically used when materials need to be mixed while moving to their destination

![]()

![]()

![]()

Price:$658.00 - $2,900.00/Set

Consult now and enjoy a 10% discount

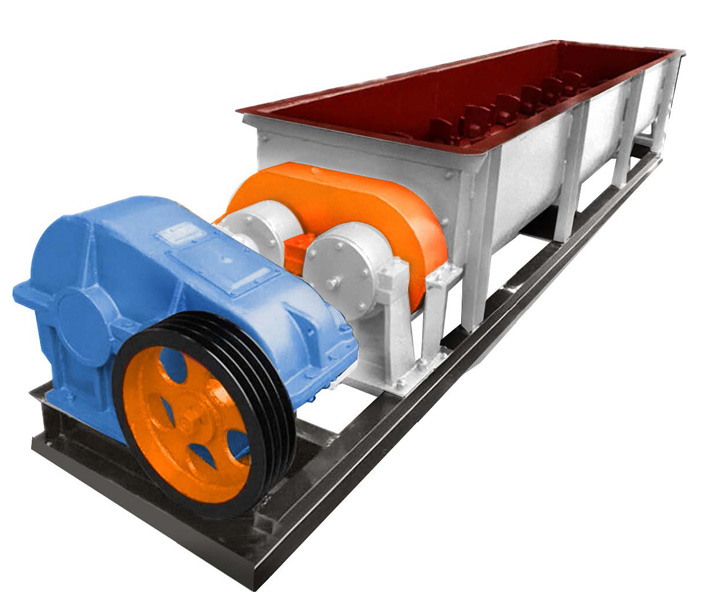

Material type: solid liquid, dry powder, granule

Each processing capacity range: 1000-3000L

Diameter of stirring blade: Φ 450-Φ 600nn

Production capacity: 10-200t/h

Application: used for mixing and mixing of clay, coal slime, nutrient soil, organic fertilizer, etc. in brick factories

Commitment:

Paddle Conveyors are basically used when material needs to mixed while moving to destination.In a paddle conveyor, the paddles are fitted at regular intervals along the length of the shaft.Its angle can be changed to control the speed of material of being carried out and its mixing.Paddles control the flow of the material there by resulting in effective stirring and mixing of the carried material.

Paddle conveyors can be either single shaft or double shaft depending upon the application and material being conveyed/mixed.Paddles are made of flat with thickness up to 10 mm.

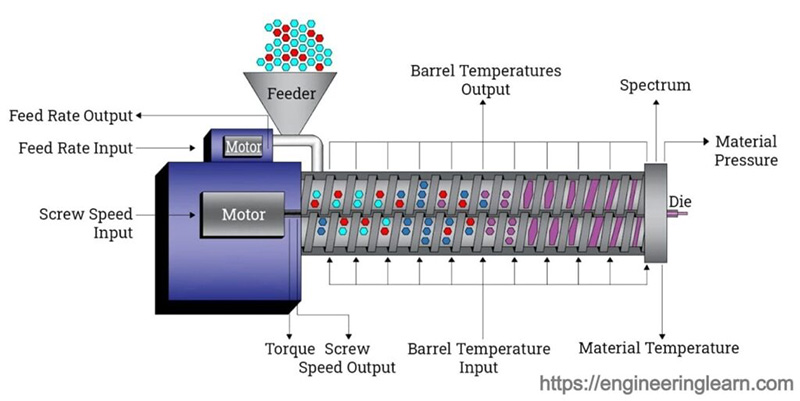

Paddle Conveyor can realize the functions of conveying, stirring, mixing and cooling at the same time. The horizontal or vertical inclined transmission of various powders, granules, and small pieces of materials through the screw on the internal shaft is especially suitable for various grains, cement, sand, and pebbles, and has strong economic benefits. . This machine is mainly used for pre-adding water and mixing before the ball forming machine in the cement plant, and can also be used for mixing other materials under the same conditions.

When the two kinds of materials enter the trough from the feeder through the feed port, the power transmission mechanism drives the helical main shaft equipped with multiple sets of blades to rotate, and the driven helical shaft and the main shaft are driven to rotate at a constant speed by the meshing transmission gear. So that the materials are evenly blended and fully stirred.

Combining conveying and mixing functions

The mixing speed is fast and the uniformity is good. It can mix and add viscous materials with 30% liquid. It is used for the transportation and mixing of chemicals and medicines, spices, minerals, sugar, pulp and other products.

Even and fast mixing

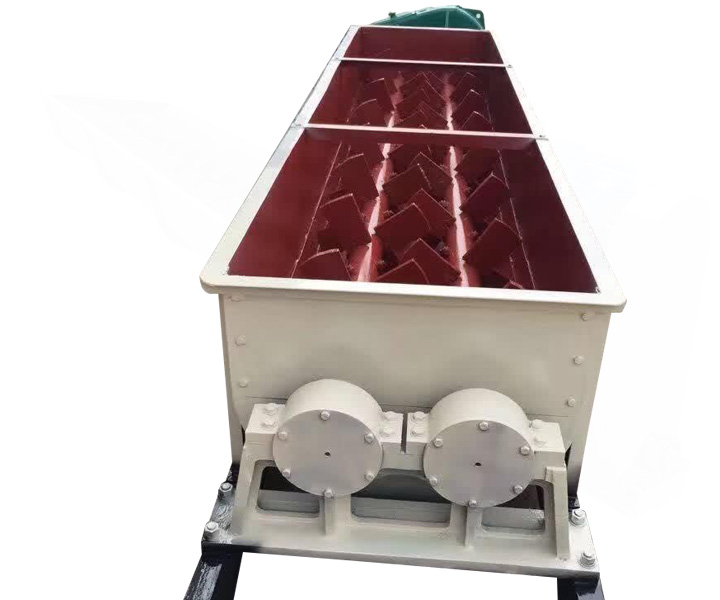

When working, there are two paddle rotors that rotate in opposite directions to stir in the middle. Because the paddles have multiple special angles, they can mix quickly and effectively regardless of the shape, size and density of the material.

sealed structure

The casing is tightly sealed, and there will be no flying ash or ash leakage.

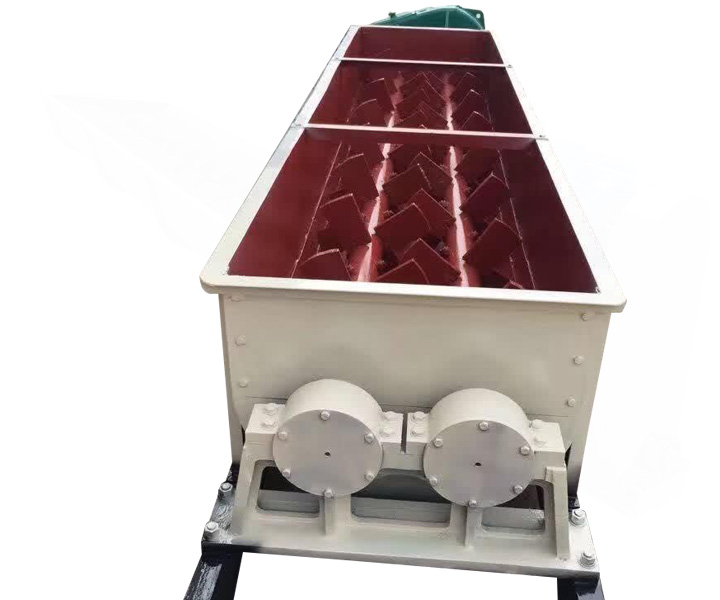

Low noise

The equipment is driven by a cycloidal pinwheel reducer, with stable rotation and low noise.

| Double shaft horizontal mixer model | HDWJ2000 | HDWJ2500 | HDWJ3000 |

| production capacity(t/h) | 8 | 10 | 18 |

| Spindle speed(r/min) | 35 | 35 | 35 |

| motor(kw) | 7.5KW4class | 11KW4class | 15KW4class |

| Dimensions (L×W×H) | 3100×750×500 | 4200×800×620 | 4700×800×620 |

| equipment weight(kg) | 1600 | 2500 | 3200 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.