Accurate to 6-level separation, the screening efficiency is as high as 90%-99%, suitable for all fine and ultra-fine powder and granular materials, especially for difficult-to-handle materials.

![]()

![]()

![]()

Price:$900.00-$8,500.00/Set

Consult now and enjoy a 10% discount

Output:4-200mm

Sieve surface inclination:5-8°

Screen box stroke:25-60mm

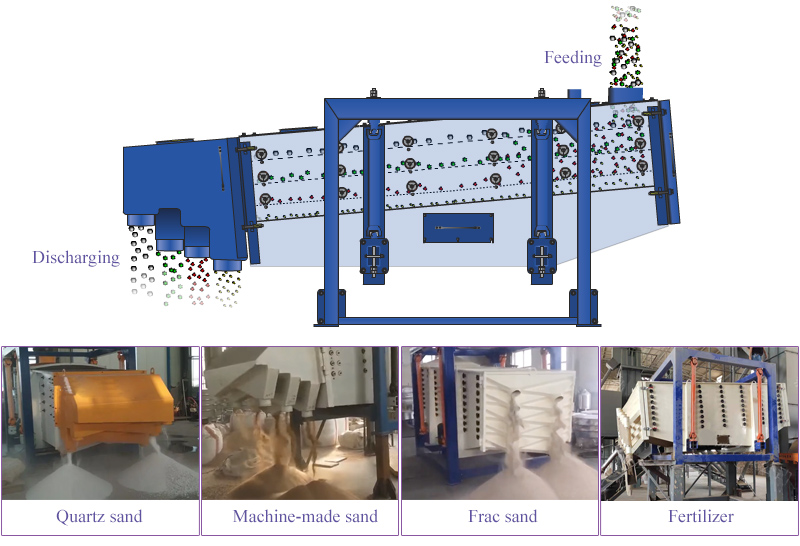

Suitable for screening: quartz sand, industrial salt, fracturing sand, machine-made sand, plate sand, dry sand, ceramsite sand, pearl sand, silica sand, polypropylene, dry mineral powder, calcium carbonate powder, mica powder, talcum powder , river sand, chemical fertilizers, etc.

Applicable materials:

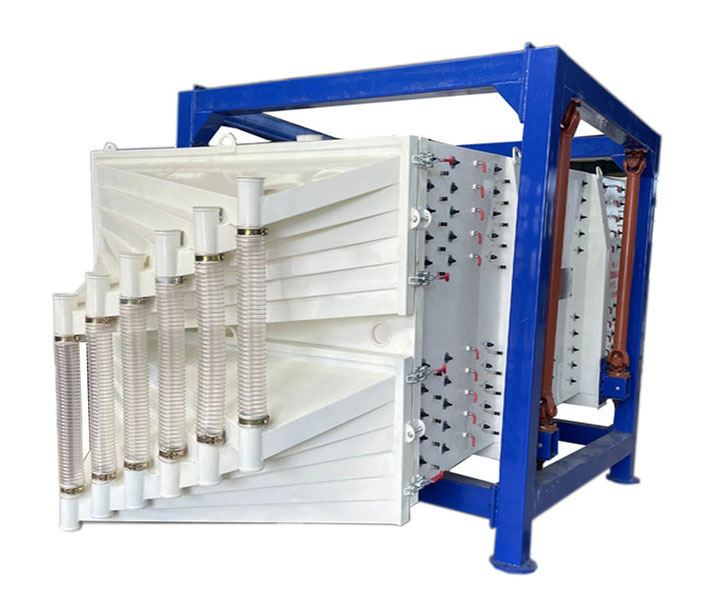

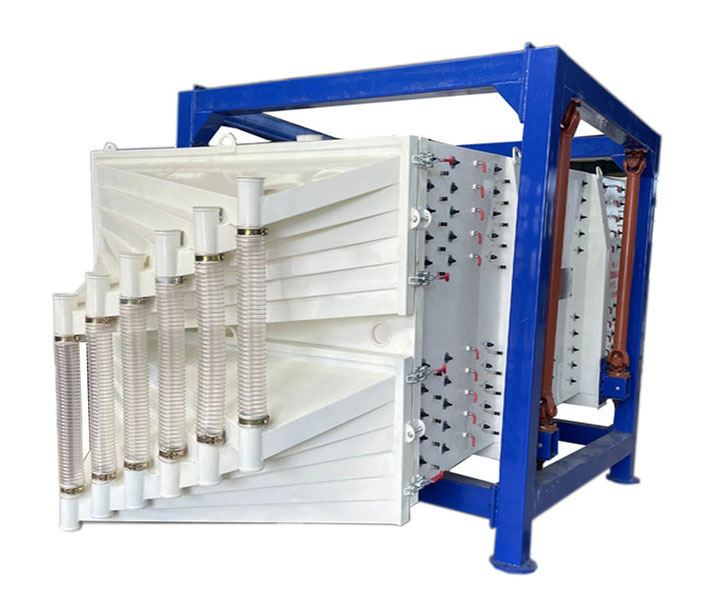

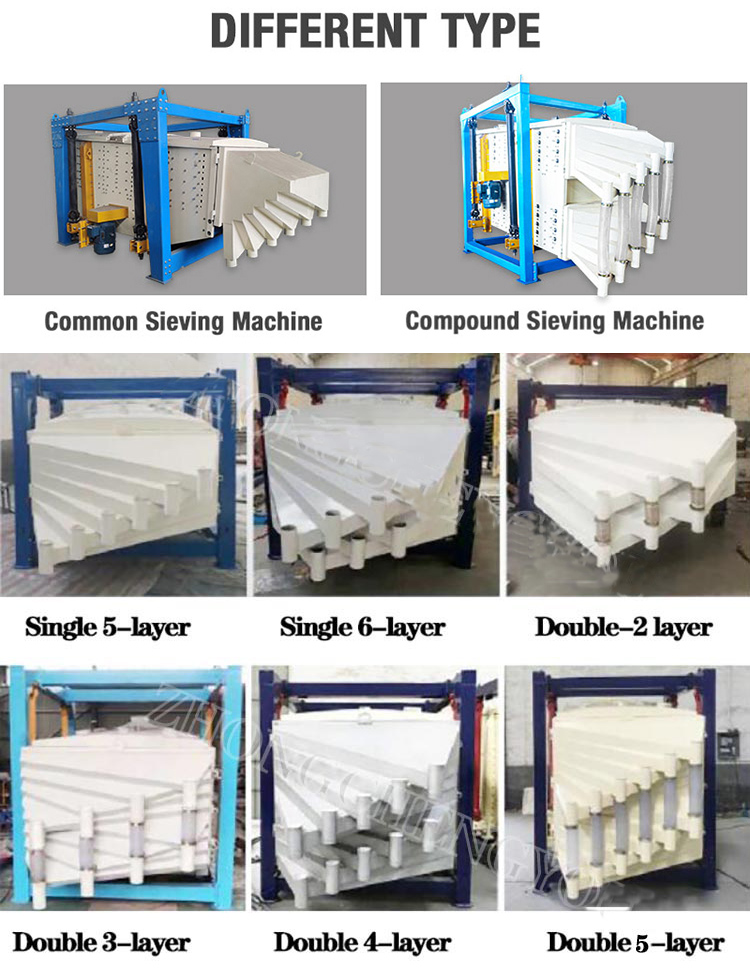

Gyratory vibrating screen, also known as reciprocating screen, is a high-efficiency and large-capacity screening equipment. Due to the principle of plane rotation, it effectively reduces the dynamic-to-static ratio and basic dynamic load of the equipment, and the efficiency is increased from 93% to 98.5%. Blocking and anti-sticking net, especially suitable for products with strong hygroscopicity, high viscosity and easy blocking.

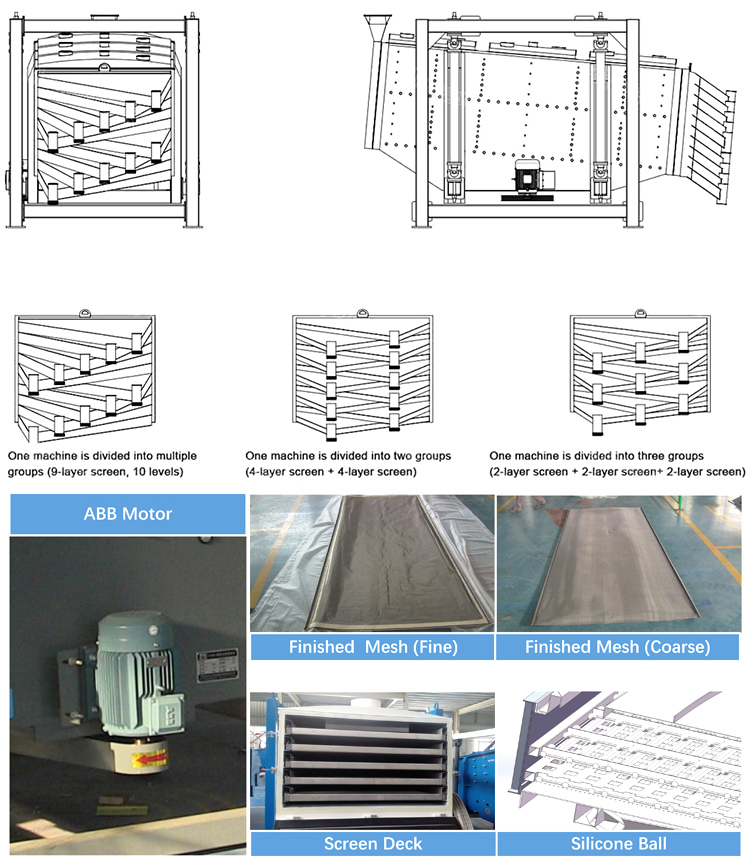

Gyratory vibrating screen adopts a unique multi-layer classification design. One machine is divided into two groups, one is equivalent to multiple machines, and the output is doubled. Generally, the design is 3~5 layers, and 4~6 sizes of materials can be graded at the same time. Users can install the number of screen layers according to their needs.

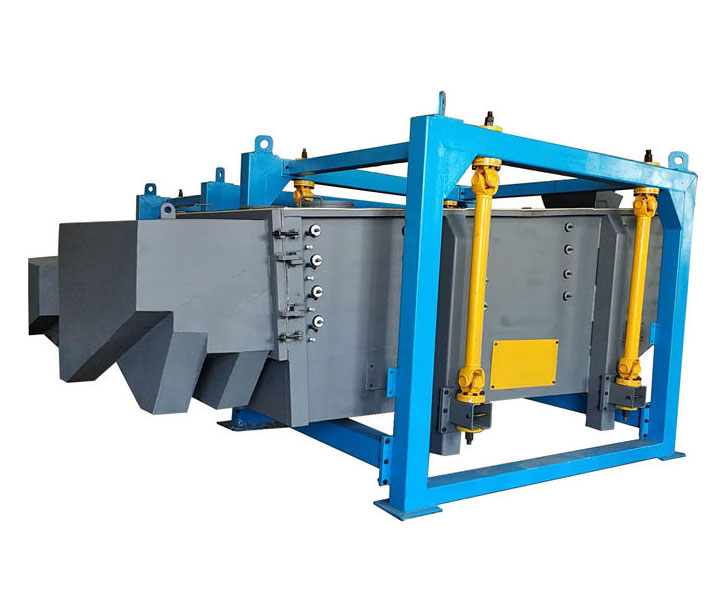

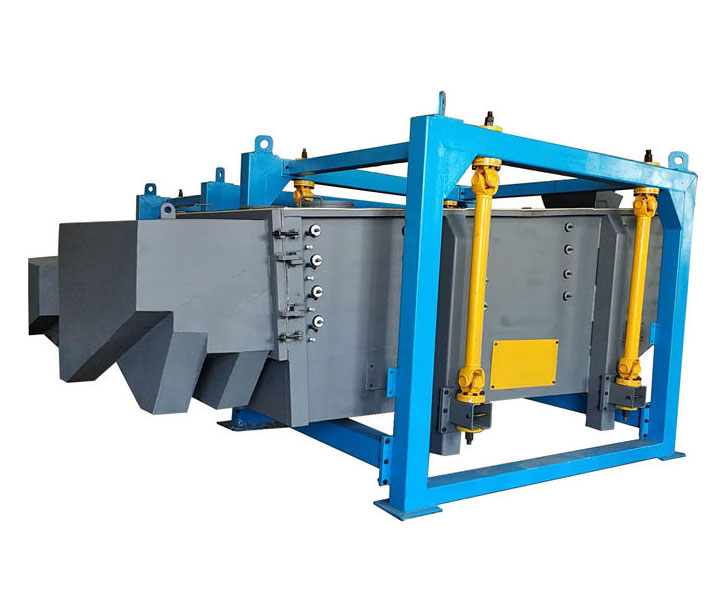

Single Vibration Source Gyratory Vibrating Screen

Single Vibration Source Gyratory Vibrating Screen is equipped with only one vibration source, has a simple structure and is easy to maintain.

Features: Suitable for materials with larger particle size and low screening accuracy requirements.

Application: some small production lines or laboratories

Double Vibration Source Gyratory Vibrating Screen

Double Vibration Source Gyratory Vibrating Screen is equipped with two or more vibrators at different parts of the screen body. The screening efficiency is higher and the net cleaning effect is better.

Features: Strong adaptability and can handle a variety of materials, including wet materials and sticky materials.

Application: It is widely used in chemical, food, metallurgical and other industries where high screening accuracy is required and large screening capacity is required.

Three-dimensional Source Gyratory vibrating screen

Three-dimensional Source Gyratory vibrating screen makes complex movements in the three-dimensional space, and the materials are subjected to multi-directional forces on the screen surface.

Features: High screening accuracy and large processing capacity

Application: Suitable for high-precision screening of metal powder, ceramic powder, etc.

Lower-Vibration Source Gyratory Vibrating Screen

The vibration source of the low-vibration rotary screen is located at the bottom or below the screen, which can reduce the impact of vibration on the upper structure of the screen machine.

Features: Suitable for materials that require high screening accuracy, such as ultra-fine powders, etc.

Application: Suitable for mining, metallurgy and other industries that require high screening stability or for screening heavier materials.

Middle-Vibration Source Gyratory Vibrating Screen

The vibration source of the medium-vibration square rotary screen is usually located in the middle or near the center of the screen surface, which can transfer materials evenly

Features: Suitable for handling materials that are difficult to screen

Application: Suitable for fine chemicals, food and other industries that require high screening efficiency and uniformity.

Gyratory Vibrating Screens are mainly used in the mining field and the building materials industry. They can be used to classify and screen ores and separate minerals of different particle sizes. Its high precision and stability make gyratory vibrating screens widely used in the mining field. In the building materials industry, gyratory vibrating screens can be used to prepare sand and gravel aggregates of various specifications to meet the needs of construction projects.

The screen surface of the gyroscopic vibrating screen is generally horizontal or slightly inclined (the inclination angle is 0°~5°). The working principle of the square pendulum screen is that after the screen machine is started, the vibrating screen, that is, the screen box reciprocates under the action of inertial force, and the screen box drives the screen surface to vibrate periodically, so that the materials on the screen surface match the screen box. Used in conjunction with the plane rotation motion. During this period, the material smaller than the sieve surface diameter will fall to the lower layer through the sieve hole and become the material under the sieve.

Operation trajectory:

The first step is the rotational movement. It occurs on the feed side of the rotary vibrating screen, prompting the material to be quickly and evenly distributed on the screen, and begins to form preliminary stratification, while advancing forward along the screen surface.

The second step is elliptical movement. When the material moves to the central area of the screen, its movement pattern changes to an elliptical shape.

The third step is reciprocating motion. As the material approaches the discharge end, its motion becomes reciprocating. At this stage, the material continues to undergo an effective stratification process until it is finally discharged from the screen surface.

Good sealing: Gyratory vibrating screen usually adopts a closed structure, which can effectively prevent dust from flying and improve the working environment.

High screening efficiency: Through the periodic movement of the screen box, the materials form a multi-directional movement trajectory, which improves efficiency.

Strong adaptability: Gyratory vibrating screen can handle a variety of materials and has strong adaptability, including wet materials, sticky materials, etc.

High screening precision: Gyratory vibrating screen can achieve high-precision screening by adjusting the vibration frequency, amplitude and screen aperture.

Mullite sand gyratory vibrating screen

Fracturing sand gyratory vibrating screen

| Model | Screen surface L*W(mm) |

Screen box stroke (mm) |

Power (kw) |

Layer | Single layer weight (kg) |

| FYB1021 | 1000*2100 | 25-60 | 3 | 1~5 | 980 |

| FYB1030 | 1000*3000 | 25-60 | 3 | 1200 | |

| FYB1236 | 1200*3600 | 25-76 | 4 | 1850 | |

| FYB1530 | 1500*3000 | 25-76 | 5.5 | 2050 | |

| FYB1536 | 1500*3600 | 25-76 | 5.5 | 2410 | |

| FYB1836 | 1800*3600 | 25-76 | 7.5 | 3880 | |

| FYB2050 | 2000*5000 | 25-92 | 11 | 5500 |

1.Device usage history: Have you used similar devices before? If you have used it, please provide the device model.

2.Material information: What material do you need to screen?

3.Capacity requirements: How many tons of material per hour do you want the equipment to process?

4.Screening specifications: How many layers of screens do you need? What is the pore size of each layer of screen?

5.Special requirements: Do you have any other special requirements for the equipment, such as dust-proof, explosion-proof, noise requirements, etc.?

Dahan gyroscopic vibrating screen manufacturer focuses on the research and development of screening equipment and has been in production for 15 years. At the same time, the company has two production bases with strong production capacity and guaranteed production quality. It can recommend selection according to user needs, provide assembly line design solutions, and also According to different usage scenarios, accessories and equipment can be customized services.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.