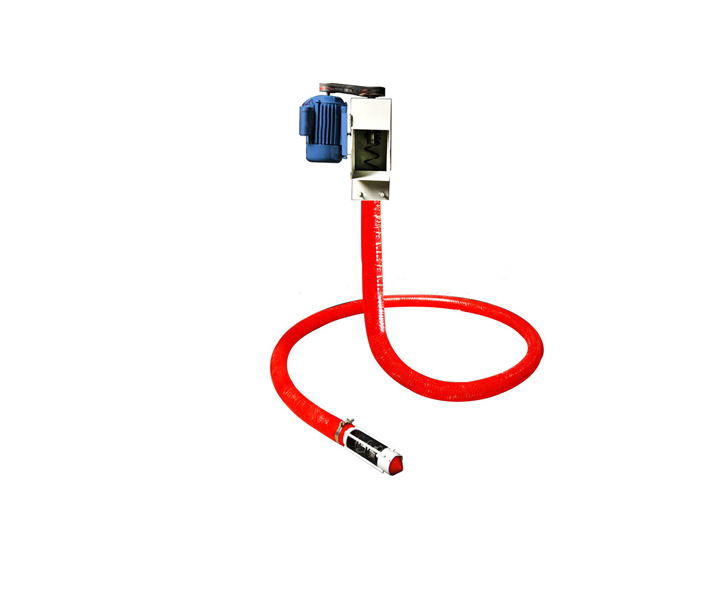

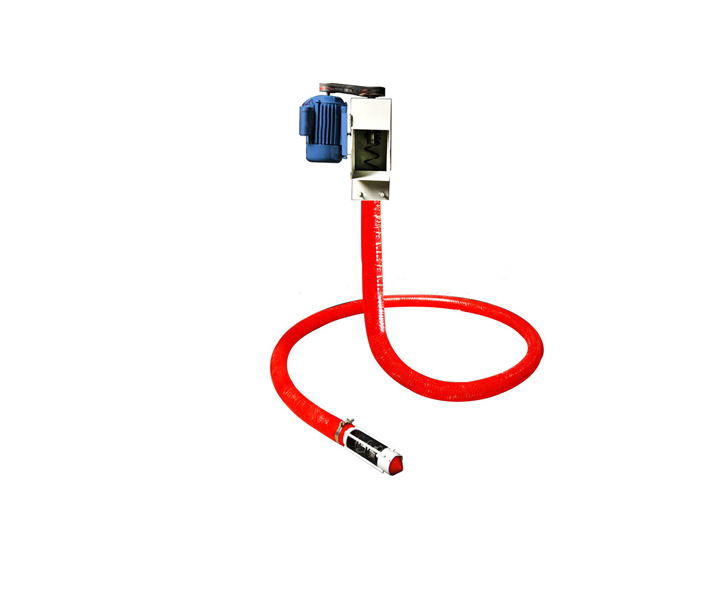

Convey powdery, granular and other small materials along the pipeline with a flexible screw

![]()

![]()

Price:$80.00-$1000.00/Set

Consult now and enjoy a 10% discount

Pipe diameter: 100mm/120mm/160mm

Conveying length: 3m-12m

Vertical height: 3m-4m

Conveying capacity: 4-20 tons/hour

Drive: single motor/three phase/Gasoline engine/diesel engine

Voltage: 220/380v or design

Conveying angle: 0-90 degrees

Application: Used in farms, feed mills, food factories, plastic factories, sand fields, etc. to transport wheat, soybean, corn, rice, sorghum, plastic, resin, rice, sand and other particles

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customizati

Flexible auger conveyor, also called flexible screw conveyor, is a versatile and efficient way to transport a variety of materials in a variety of industries and applications, providing design flexibility and ease of use, it uses a flexible auger or screw conveyor Material is conveyed along a pipe in which a screw or auger rotates, moving the material forward in a continuous flow. The screw or auger in a flexible auger conveyor is made of a flexible material, such as polyethylene or stainless steel wire, which allows it to bend and bend as it travels through the pipe. This flexibility allows the conveyor to maneuver around obstacles and through tight spaces, making it ideal for use in applications where space is limited.

The flexible auger conveyor can convey many types of free-flowing and non-free-flowing bulk materials, including powders, granules and pellets, as well as small irregularly shaped materials.

1. Agriculture: Commonly used in agriculture to transport grain and other small materials between grain storage bins, trucks and other handling equipment.

2. Food processing: used to transport grain and other small materials, such as nuts, seeds, etc., for processing and packaging.

3. Mining industry: used to transport minerals, ores and other small materials.

4. Waste management: Used to transport small materials such as sawdust and wood chips.

5. Construction: Used in construction applications for conveying small materials such as sand and gravel.

There are several types of flexible auger conveyors available, each designed to meet specific application requirements. Here are some of the common types of flexible auger conveyors:

1. Portable flexible auger conveyor: Designed for small operations such as farms and small grain handling facilities. They are compact and easy to move, making them ideal for transporting grain between storage bins and trucks.

2. Truck-mounted flexible auger conveyor: Mounted on a truck or trailer for easy transport between grain loading and unloading locations. They are typically used in larger grain handling facilities.

3. PTO-driven flexible auger conveyor: Are powered by a tractor's power take-off (PTO), making them ideal for use on farms and other agricultural operations. They are commonly used to transport grains between storage bins and trucks.

4. Electric-powered flexible auger conveyor: Are powered by electricity, making them ideal for use in facilities with access to an electrical power source. They are commonly used in smaller grain handling facilities.

Flexible auger conveyor consists of a tube that contains a flexible screw or auger that rotates inside the tube, moving the material along the length of the tube to eventually exit the outlet end of the conveyor, as the screw or auger rotates, it Continuous flow moves the material forward, and the flexible material of the screw or auger allows it to flex and bend as it passes through the pipe, allowing it to maneuver around obstacles and through tight spaces.

Versatility

It can be used to convey a wide range of materials, including powders and granules. They can also be designed to run in different orientations, including horizontal, inclined or vertical.

Save space

Typically smaller and more compact than traditional conveyor systems, ideal for applications where space is limited.

Customizable

Can be easily customized to meet specific application requirements, including the type of material being conveyed, flow rate and conveyor orientation.

Easy to install and maintain

Easy installation and minimal maintenance make it a cost-effective solution for many applications.

Handle materials gently

Gentle handling of materials reduces the risk of damage to transported materials. This is especially important in industries such as food processing and pharmaceuticals, where product integrity is of paramount importance.

Energy saving

Energy efficient, requiring less electricity to operate compared to traditional conveyor systems, reducing production costs.

Difference Between Flexible Auger Conveyor and Ordinary Auger Conveyor

The main difference between a flexible auger conveyor and an ordinary auger conveyor lies in their design and function.

| Difference | Flexible Auger Conveyor | Ordinary Auger Conveyor |

| Design | Consisting of a flexible helical screw enclosed in a flexible housing, it is designed to fit in tight spaces and around corners. | Consists of a solid or hollow tube with helical blades designed to move material along the tube. |

| Function | Used to move dry or semi-solid materials from one place to another. The screw rotates, moving the material along the conveyor. | Used to move dry or semi-solid materials from one place to another. The screw rotates, moving the material along the conveyor. |

| Advantages | Bendable, mobile, easy to carry, low breakage rate, less than 0.2%, save space, low maintenance, low cost | The ability to move large volumes of material at consistent speeds and the ability to operate in harsh environments can be costly |

Flexible screw auger conveyor

Flexible auger conveyor for grain

| Model No. | Length (Meters) |

Pipe diameter | Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

How to choose a suitable flexible auger conveyor?

1. What is your capacity do you need?

100mm with 5.7t/h

120mm with 7-10t/h

160mm with 10-20t/h

2. How many lengths do you need?

3. What is your need about power?

There are single motor/three phase/gasoline engine/diesel engine

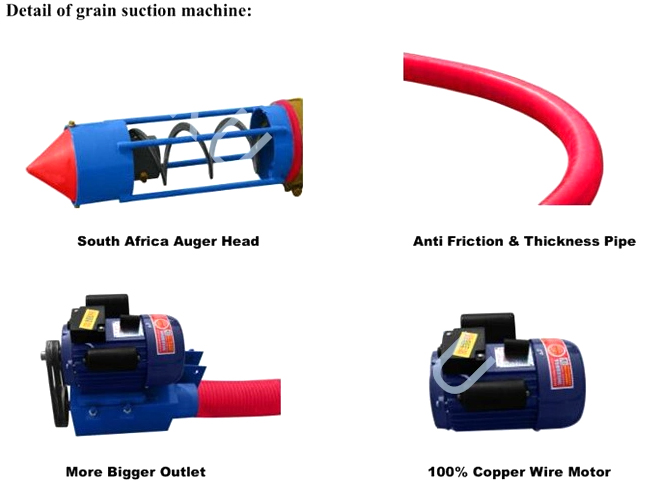

The conveyor consists of three main components: flexible polymer hose, helical screw and drive motor.

The following is the structural breakdown of the hose screw conveyor:

Flexible polymer hose: The flexible polymer hose is the outer shell of the conveyor. It is made of durable polymer materials such as polyurethane or PVC, and is designed to be flexible and bendable. The hose is available in various lengths and diameters to meet the specific needs of the application.

Auger Screw: The Auger Screw is the internal component of the conveyor. It is a helical metal or plastic screw that runs the length of the hose. The screw is connected to a drive motor and rotates to move material along the length of the conveyor.

Drive motor: The drive motor is the power source of the conveyor. It is usually an electric motor attached to the end of the conveyor and driving the auger screw.

When selecting a flexible auger conveyor manufacturer, it is important to consider specific application requirements, as well as the manufacturer's reputation and customer service. It is also important to ensure that the machine complies with the safety and regulatory standards in the intended application.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.