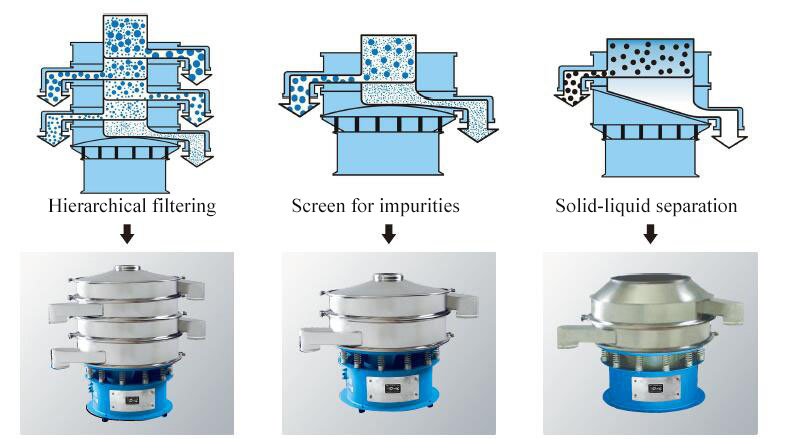

Used to screen dry powder or granular products as well as wet products and liquids, it can eliminate foreign matter in the product through continuous filtration

![]()

![]()

Price:$420.00-$3600.00/Set

Consult now and enjoy a 10% discount

Diameter: 400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Material: Q235 carbon steel, stainless steel 304 or 316L, polypropylene plastic

Motor power: 0.25Kw to 2.2Kw or customized

Application: Widely used in a variety of applications including solid-liquid separation, liquid filtration, dewatering, sludge treatment and particle classification. They can be used in processes such as wastewater treatment, industrial filtration, product recycling and manufacturing quality control.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Filter shaker, also known as a shaking filter or vibratory filter, is a device used for separating solid particles from a liquid by passing it through a vibrating sieve or filter media. It is commonly used in various industries, including wastewater treatment, chemical processing, food and beverage, pharmaceuticals, and more.

Filter shakers are widely used for various applications, including solid-liquid separation, liquid filtration, dewatering, sludge processing, and particle classification. They can be employed in processes such as wastewater treatment, industrial filtration, product recovery, and quality control in manufacturing.

The main purpose of a filter shaker is to achieve solid-liquid separation or particle classification. It is commonly used in various industries, including food processing, pharmaceuticals, chemicals, mining, and wastewater treatment. Some specific applications of filter shakers include:

1.Solid-liquid separation: Filter shakers are used to separate solid particles from liquids. This can be done to remove impurities from liquids or to recover valuable solids from a liquid stream.

2.Particle classification: Filter shakers can classify particles based on their size or shape. This is useful in industries where specific particle size ranges are required for product quality or process efficiency.

3.Dewatering: Filter shakers can be used to remove excess moisture from solids, thereby facilitating further processing or disposal.

4.De-dusting: Filter shakers help remove dust or fine particles from materials, improving the quality and cleanliness of the final product.

5.Safety screening: Filter shakers are used for safety screening to ensure that no oversized or foreign particles are present in the product, preventing equipment damage or product contamination.

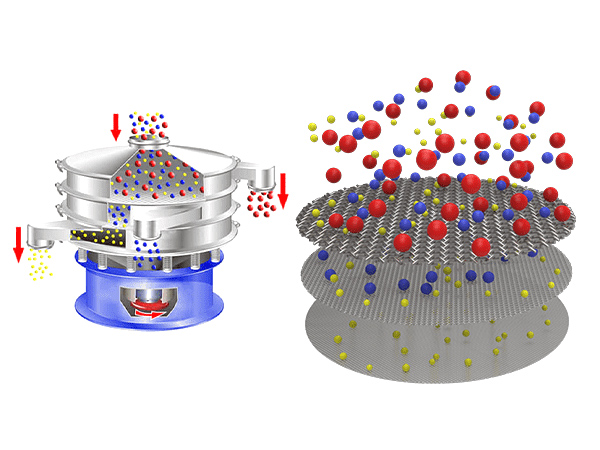

The filter shaker uses a vertical motor as the vibration source. The upper and lower ends are equipped with eccentric hammers to convert the rotation of the motor into a horizontal-vertical-tilt three-dimensional motion, and then this motion is transmitted to the screen surface, so that the material is gradually expanded on the screen surface Open line movement, rotary vibrating screen has the advantages of long material running trajectory and high screen surface utilization rate. It can carry out fine screening and probability screening of materials.

By changing the angle and mass of the upper and lower eccentric blocks of the vibrating motor, the vibrating motor can drive the equipment to produce different vibration forces, thereby changing the vibration amplitude in the horizontal or vertical direction, thereby changing the flow rate and efficiency of the screening.

Efficient particle separation

The vibration of the screen or filter media helps separate particles quickly and efficiently based on their size, resulting in a clarified and clean product.

High separation capacity

They can process large amounts of material in a relatively short period of time, thereby increasing productivity and throughput in the production process, with a throughput of up to 3300kg per hour.

Precise particle size control

Selecting the appropriate filter media or mesh size allows precise separation of particles within the desired size range, ensuring consistent product quality and meeting specific requirements.

Continuous operation

Can be operated continuously, allowing for uninterrupted separation and processing. They can be integrated into automated systems to provide consistent and efficient operations without human intervention.

Save costs

Its reusable screen mesh or mesh reduces the frequency and cost of screen replacement.

Customizable and adjustable

Filter media or screens can be selected based on the particle size distribution and characteristics of the material being processed.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Filter shaker is a common solid-liquid separation equipment that screens materials through a vibrating screen. It is widely used in various industry scenarios that require solid-liquid separation and particle size classification.

1. Food industry

Our filter shaker can be used to process starch, powdered sugar, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.

2. Pharmaceutical industry

Chinese medicine powder, Chinese medicine liquid, western medicine powder, western medicine liquid, Chinese and western medicine granules and other powders, liquids and granules can be sieved

3. Chemical industry

It can be widely used in the screening of resin powder, paint, washing powder, micro powder, paint, soda ash, lemon powder, rubber, plastic and other materials.

4. Metallurgical industry

Screen filter shaker can be used to screen electromagnetic materials, metal powder, electrode powder, etc.

| Product | Purpose of usage | Mesh size | Capacity |

| food additive powder | Separate and remove impurities | 40 mesh | 500 kg/h |

| Ore particles | Grading and classification | 80 mesh | 1000 kg/h |

| building material pellets | Screening and separation of particles of different sizes | 60 mesh | 2000 kg/h |

| pharmaceutical powder | Screening of powders and removal of large particle impurities | 100 mesh | 300 kg/h |

| chemical particles | Separating fine particles to obtain products of specific particle sizes | 120 mesh | 1500 kg/h |

| grain powder | Removal of impurities and classification to obtain products of different particle sizes | 50 mesh | 800 kg/h |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.