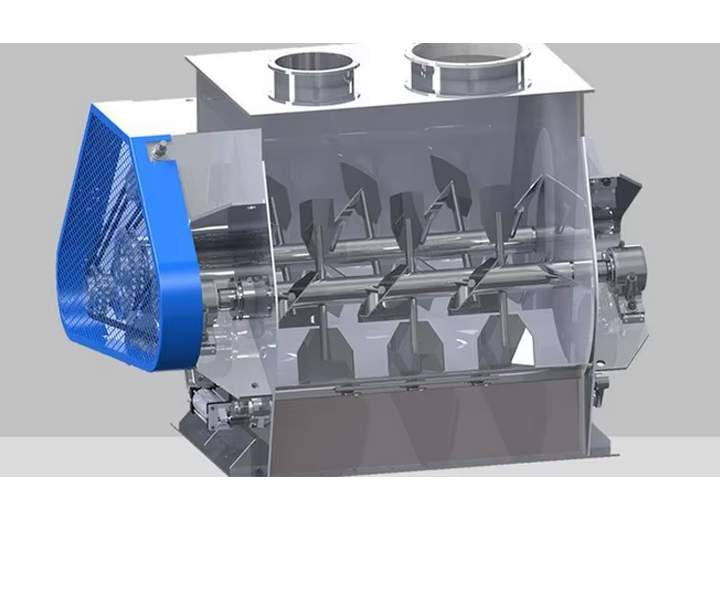

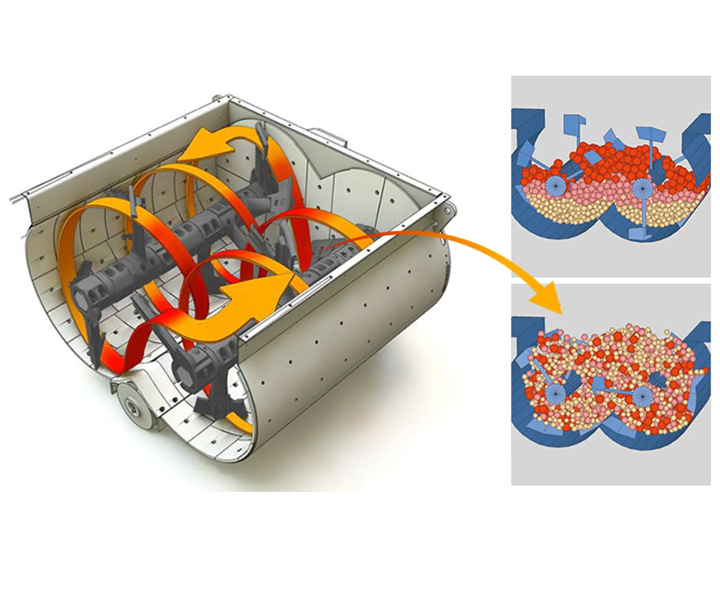

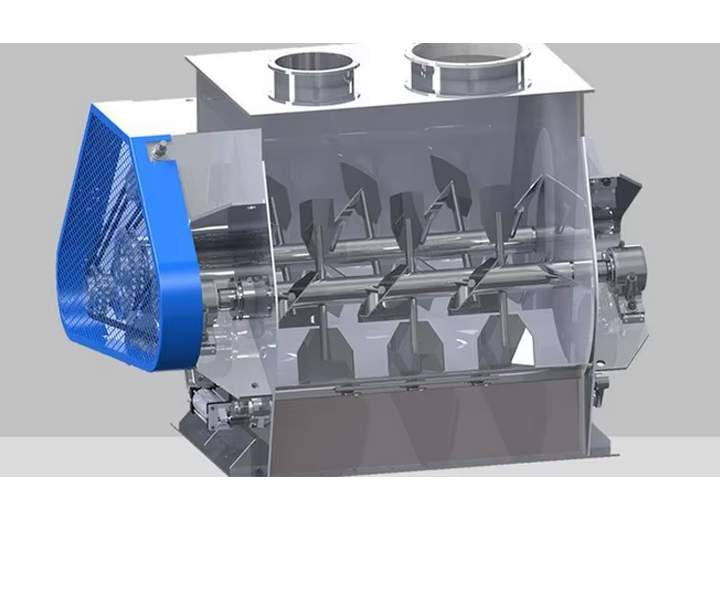

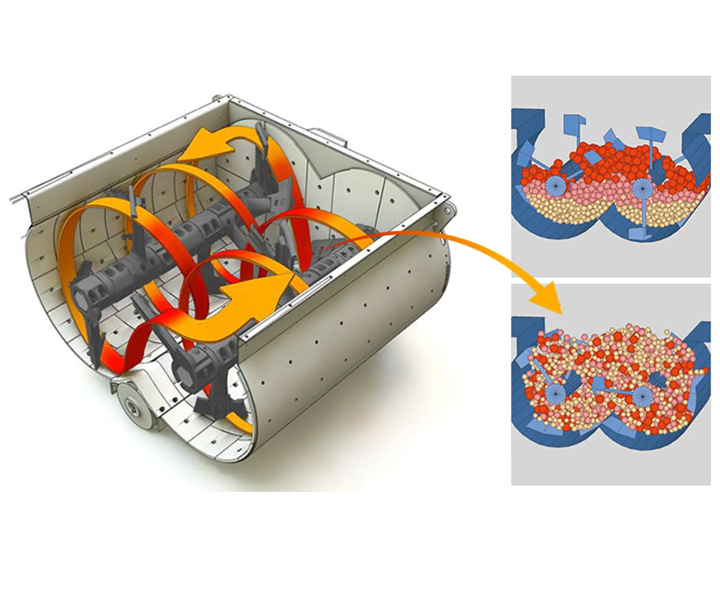

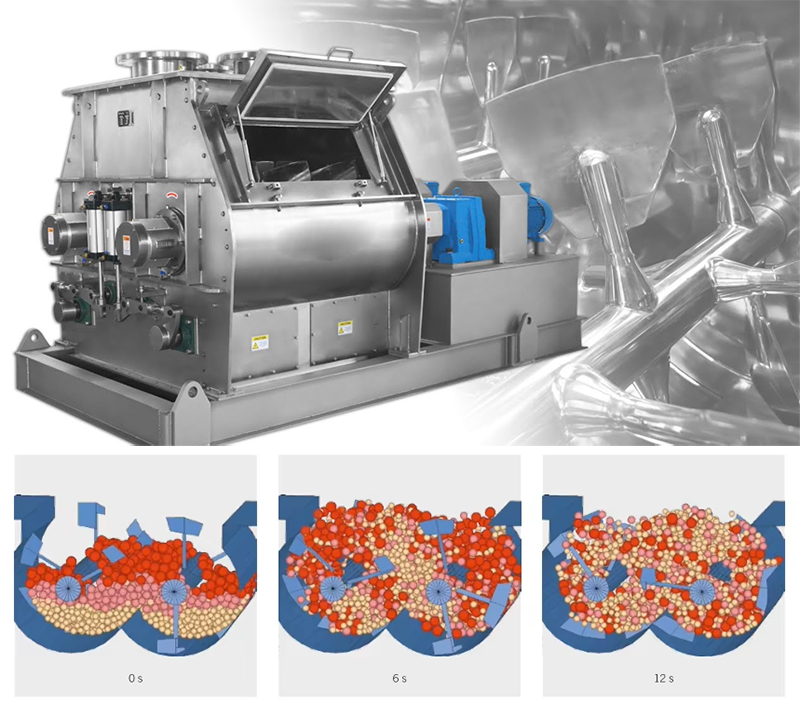

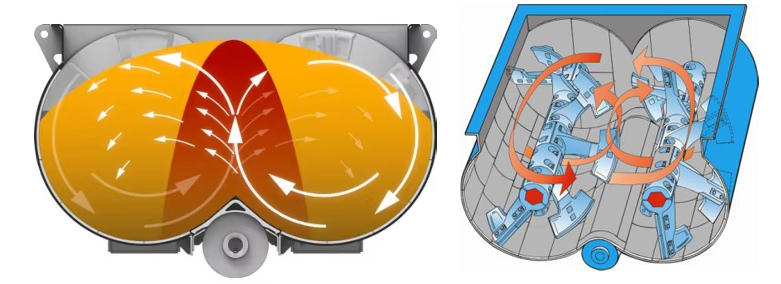

Adopting the convection mixing principle (symmetrical angled blades), it discharges faster, more evenly and cleanly than the ribbon mixer.

![]()

![]()

![]()

Price:$500.00-$6,000.00/Set

Consult now and enjoy a 10% discount

Mixing speed: 3-5 minutes (feed: 3 minutes mortar: 5 minutes)

One-time mixing: 100-6000 (kg)

Capacity: 0.1cbm-20cbm

Material: Carbon steel or stainless steel

Application: Anti-crack mortar, thermal insulation mortar, bonding mortar, plastering mortar, floor mortar and other dry mortars with high mixing uniformity requirements and medium and high-grade putty powder

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

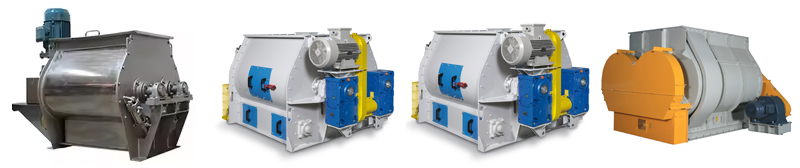

Double Shaft Paddle Mixer is a device used to mix powdered, granular, flake, block and thin materials. It is a device that uses a pair of spiral shafts with stirring blades to synchronously rotate, spray, humidify and stir the powdered materials while conveying them. It can be used to mix and crush clay materials in the ceramsite industry; powder and other raw materials and aggregates, additives, etc. are evenly mixed and mixed.

Double shaft paddle mixer uses the most powerful motor, which can mix materials evenly in the shortest time, and is particularly suitable for mixing materials with large differences in specific gravity, mesh size, and fluidity. It can select batch working capacity from 0.1cbm to 20cbm, and the unloading and driving methods can be selected as manual, pneumatic, and electric.

The working principle of a double shaft paddle mixer is based on the principle of convection mixing. It uses the upward motion of the material in the mixer to form a fluidized layer, produce instantaneous weightlessness, and achieve the best mixing state. The rotation speed of the equipment is usually 50%-80% of the critical speed. The paddle moves the material from A to B at a specific angle, and then achieves all-round mixing through axial movement.

During the working process, the transmission device drives the two blade shafts with stirring blades to rotate synchronously. When the material enters the machine slot from the feeding port, the water spraying device immediately sprays water to change the material from dry to wet; while humidifying, the wet material is continuously stirred and mixed with each other under the action of the spiral stirring blades, and moves toward the discharge port, and finally the qualified material is unloaded from the discharge port.

Efficient mixing

The counter-rotating shafts with paddles provide high intensity mixing action, ensuring that materials are thoroughly mixed and a uniform blend is achieved.

Versatility

Double paddle mixers can handle a wide range of materials, including powders, granules, pastes and liquids, making them suitable for different applications.

Short mixing time

Due to the high intensity mixing action, double shaft paddle mixers can achieve a uniform mix in a relatively short time, making the production process more efficient.

Uniform discharge

These mixers are designed to ensure uniform discharge of mixed materials, reducing the risk of component separation or uneven distribution.

High throughput

The larger mixing chamber volume can accommodate more material and is suitable for large-scale production, starting at 500 kg at a time.

Gentle mixing

The mixer's paddles produce a gentle mixing action, suitable for fragile or heat-sensitive materials that need to be handled carefully during the mixing process.

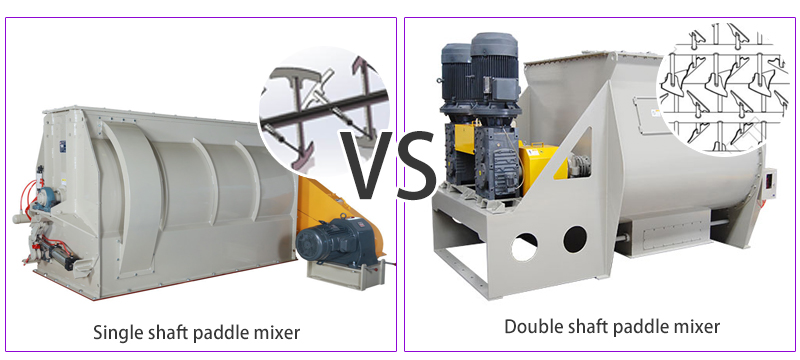

Here's a table summarizing the key differences:

| Difference | Single Shaft | Double Shaft |

| Shafts | One shaft | Two counter-rotating shafts |

| Mixing Action | Lifting and throwing | Shearing, folding, intense mixing |

| Material Handling | Moderate viscosity | High viscosity, pastes, demanding mixing |

| Cost | Generally lower | Potentially higher |

| Complexity | Simpler design | More complex design |

It is suitable for stirring viscous materials such as sludge, oil sludge, coal slime, bentonite, etc. The materials are very viscous and difficult to stir.

| model | SJ-30 | SJ-32 | SJ-35 | SJ-40 | SJ-42 | SJ-46 | SJ-50 | SJ-60 |

| Center distance between two axes/mm | 300 | 320 | 350 | 400 | 420 | 460 | 500 | 600 |

| Spindle speed/(r/min) | 53 | 53 | 53 | 53 | 53 | 53 | 45 | 45 |

| Tank length/mm | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 |

| Equipment capacity/m³ | >6-8 | >8-10 | >10-13 | >13-24 | >24-28 | >28-35 | >35-38 | >38-80 |

| Motor power/kW | 22 | 30 | 37 | 45 | 55 | 75 | 75 | 110 |

| Note: 1. The capacity in the equipment table is the capacity when the blade inclination angle is 15 degrees and the filling system is 0.33. 2. The power in the equipment table refers to the power when the bulk density is 1.0-1.3. 3. This series of double-shaft mixers are equipped with ZQ series soft-tooth reducers and ZQL axial pneumatic clutches. |

||||||||

It is suitable for humidifying and stirring powdery and small granular materials. The materials have low viscosity and are easy to stir.

| model | ZJ250 | ZJ300 | ZJ400 | ZJ500 | ZJ600 | ZJ650 | ZJ700 | ZJ800 | ZJ900 | ||||||

| Stirring blade rotation diameter(mm) | 250 | 300 | 400 | 500 | 600 | 650 | 700 | 800 | 900 | ||||||

| Spindle speed(r/min) | 62.6 | 63.5 | 53 | 53 | 53 | 53 | 45 | 45 | 45 | ||||||

| Tank length(mm) | 1500-2500 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-6000 | 2000-6000 | 3000-4000 | 3000-4000 | 3000-4000 | ||||||

| Distance between inlet and outlet(mm) | 900-1900 | 1400-3400 | 1300-3300 | 1300-3300 | 1200-5200 | 2200-5200 | 2200-3200 | 2200-3200 | 2200-3200 | ||||||

| Equipment capacity(m³/h) | 0-3 | >3-6 | >6-12 | >12-25 | >25-35 | >35-45 | >45-50 | >50-70 | >70-100 | ||||||

| Motor power/kW | 7.5 | 11 | 2000≤Groove length<3000 | 3000≤Groove length≤4000 | 2000≤Groove length<3000 | 3000≤Groove length≤4000 | 2000≤Groove length<3000 | 3000≤Groove length≤5000 | 5000≤Groove length≤6000 | 2000≤Groove length<3000 | 3000≤Groove length≤5000 | 5000≤Groove length≤6000 | 55 | 75 | 90 |

| 15 | 18.5 | 18.5 | 22 | 30 | 37 | 45 | 37 | 45 | 55 | ||||||

| Note: 1. The capacity in the equipment table is the capacity when the blade inclination angle is 15 degrees and the filling factor is 0.33; 2. The power in the equipment table refers to the power when the bulk density is 1.0-1.3. 3. This series of twin-shaft mixers are equipped with ZSY series hard-toothed reducers and YOX series hydraulic couplers. |

|||||||||||||||

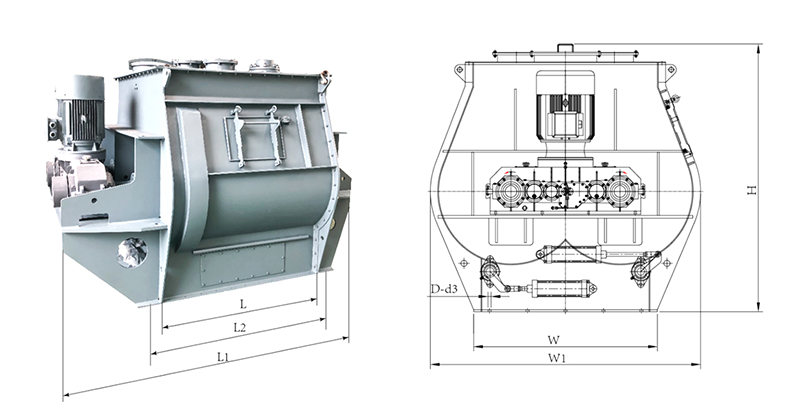

Double shaft paddle mixer has a simple and effective structural design, which mainly consists of a main structure, a twin-shaft design, paddles or agitators, a transmission device, a feed port and a discharge port, a mixing chamber and a control system to achieve efficient and uniform mixing.

1. Helical Paddles: Shaped like a screw or spiral. Suitable for mixing powders, granules, and some pastes.

2. Ribbon Paddles: Flat, ribbon-like paddles that may be single or double.Effective for both conveying and mixing. They create a strong shearing action, which is crucial for breaking down lumps and ensuring thorough dispersion of ingredients.Widely used for a variety of materials, including pastes, slurries, and viscous liquids.

3. Intermeshing Paddles: Paddles on the two shafts are designed to intermesh with each other. Create intense shearing and folding action due to the close contact between the paddles. Ideal for high-viscosity materials and those requiring very thorough mixing, such as pastes and doughs.

4. Anchor Paddles: Large, flat paddles that anchor the material to the bottom of the mixer.Prevent the material from accumulating at the bottom and ensure that all parts of the material are subjected to the mixing action.

1. Material selection

The materials can be carbon steel, manganese steel, 304, 316L, 321; in addition, different materials can be used in combination for the parts in contact with the raw materials and the parts not in contact with the raw materials. The surface treatment of stainless steel includes sandblasting, brushing, polishing, and mirror polishing, which can be used in different parts of the mixer.

2. Driven unit

The drive device, power, and speed vary according to the raw materials, starting method, and processing technology. Due to the meshing relationship of the blades, the dual-axis drive device must have synchronization capabilities. The four different drive combinations launched by Shengli Company can meet the different requirements of two synchronous gearboxes, dual output gearboxes, dual synchronous planetary gearboxes, and reducer and chain combinations.

3. Mixing device

According to the properties of the raw materials, the tray can be adjusted and designed accordingly, such as adding wear-resistant plates, Teflon plates, and serrated trays. The dual-axis paddle mixer can also add high-speed crushing bars in the barrel to disperse the materials as they flow.

4. Discharge device

The standard valve of the dual-axis paddle mixer is a dual pneumatic flat fin valve. When the valve is closed, the flat fins fit perfectly with the mixing cylinder, leaving no mixing dead zone and providing a better mixing effect.

Food Industry: Used for mixing ingredients in the production of snacks, cereals, and baked goods.

Chemical Industry: Ideal for blending powders, granules, and pastes in chemical formulations.

Pharmaceuticals: Used for mixing active ingredients and excipients in drug formulations.

Construction Materials: Commonly used for mixing dry mortar, concrete additives, and other construction materials.

Animal Feed Production: Efficiently blends feed ingredients to ensure uniform nutrient distribution.

Plastic and Rubber: Used for mixing additives and fillers in the production of plastic and rubber products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.